Everything You Need to Know About Automotive Electrical Bus Bars

As vehicles evolve with more advanced electrical systems, components like the automotive electrical bus bar play an increasingly vital role in ensuring efficiency, reliability, and safety. This article provides a comprehensive exploration of automotive electrical bus bars, including their design, applications, advantages, and much more. By the end, you’ll have a thorough understanding of why these components are indispensable in modern vehicles.

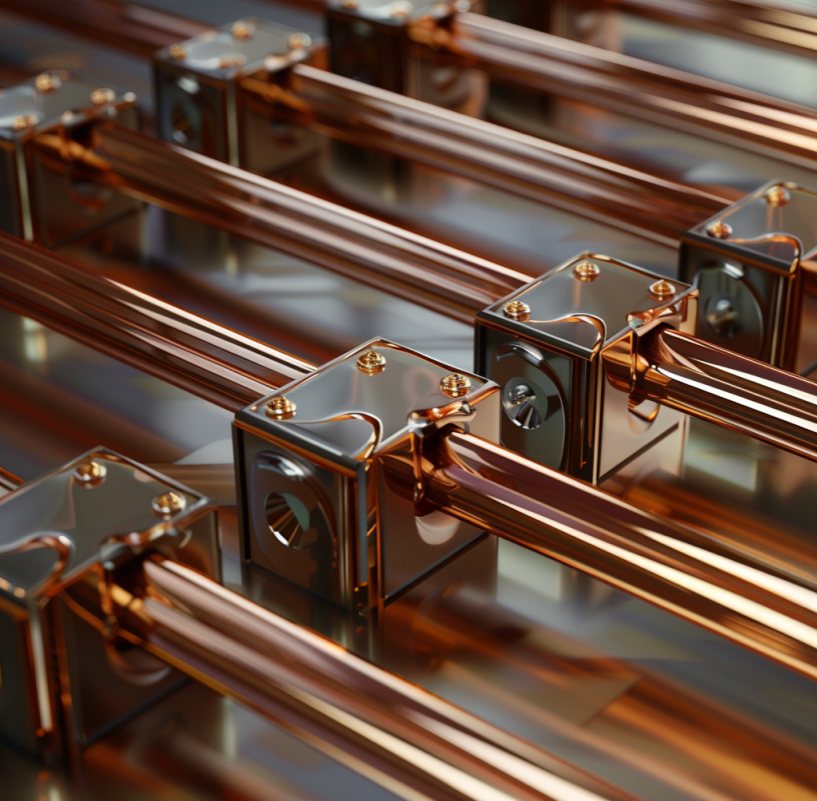

What is an Automotive Electrical Bus Bar?

An automotive electrical bus bar is a conductive strip or bar used to distribute electrical power efficiently across multiple circuits in a vehicle. Its design is optimized for compactness and reliability, ensuring seamless power flow to critical automotive systems.

Bus bars are typically made of high-conductivity materials like copper or aluminum and are often coated or laminated to provide insulation and protection against environmental factors such as moisture and corrosion. Unlike traditional wiring harnesses, which can become complex and bulky, bus bars offer a simplified and organized method for managing electrical connections.

Key Characteristics of Automotive Electrical Bus Bars:

- High Conductivity: Ensures minimal power loss during distribution.

- Compact Design: Saves space in increasingly tight automotive layouts.

- Durability: Withstands heat, vibration, and other automotive stresses.

The Role of Bus Bars in Automotive Applications

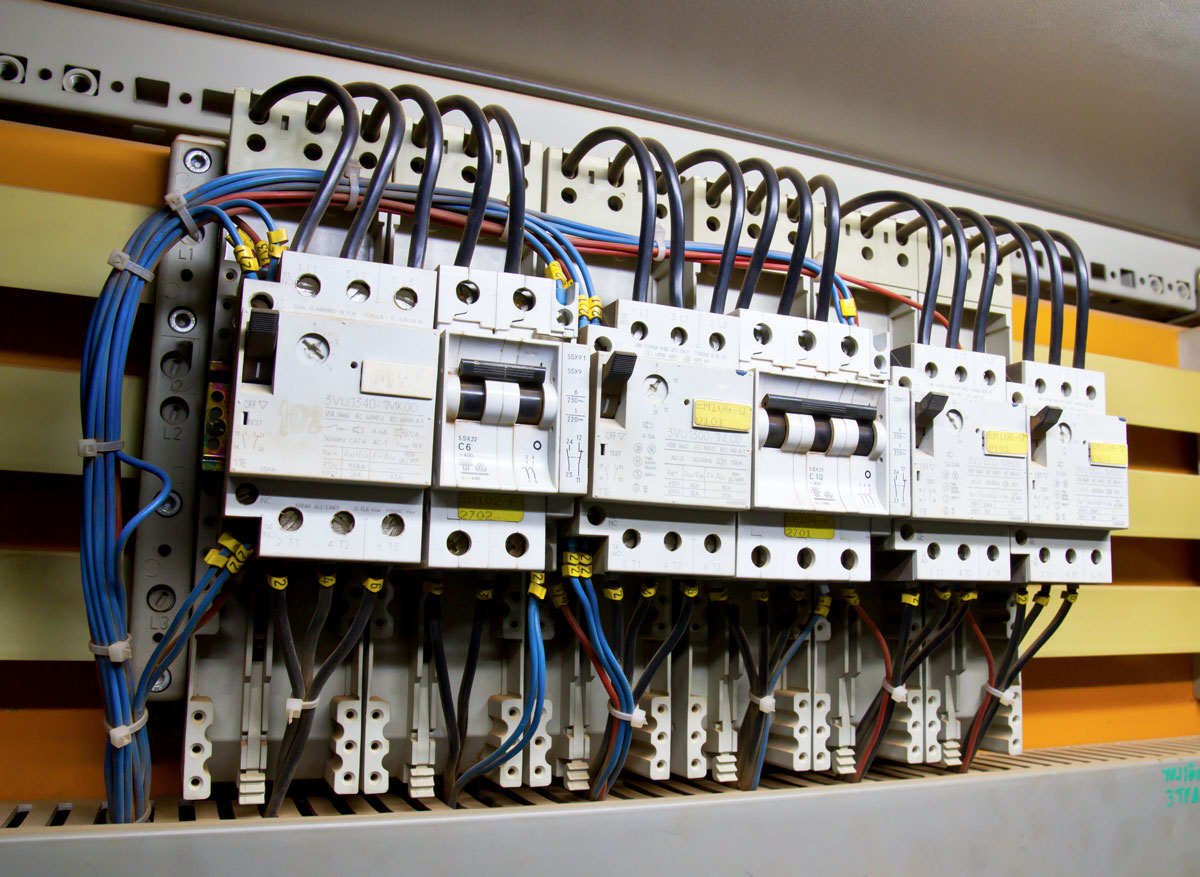

In today’s vehicles, the electrical system is a complex network powering everything from essential functions like ignition and lighting to advanced features like autonomous driving sensors and infotainment systems. The automotive electrical bus bar serves as the central hub, connecting various components efficiently.

How Bus Bars Work:

- They consolidate power distribution, replacing bulky wiring harnesses with a single, efficient component.

- They provide a low-resistance path for electricity, ensuring consistent power delivery to all connected systems.

Types of Automotive Electrical Bus Bars

Bus bars come in various designs to cater to the diverse needs of automotive systems. Each type is suited for specific applications based on factors like flexibility, current capacity, and environmental conditions.

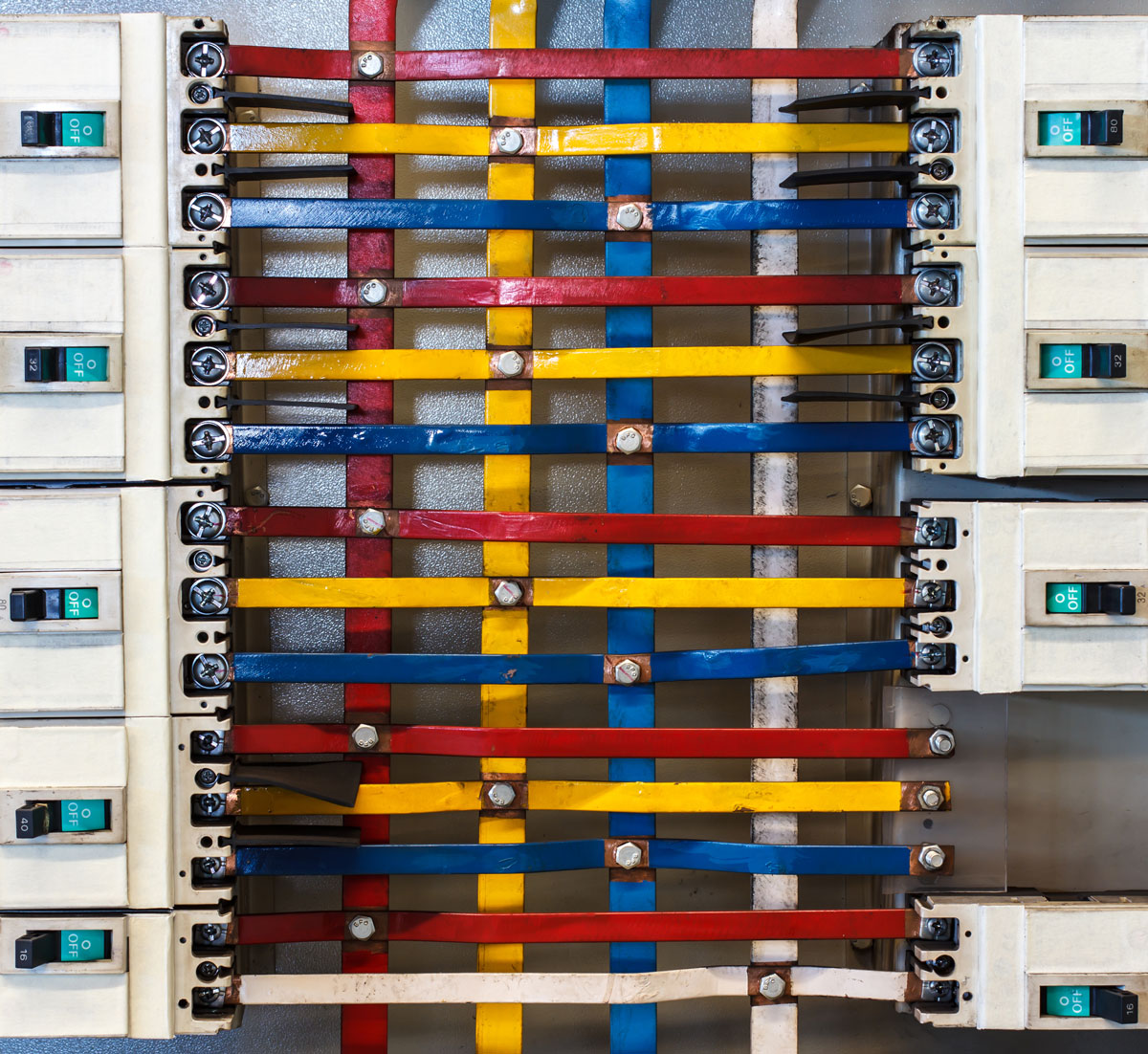

a. Solid Bus Bars

- Made from a single piece of conductive material, typically copper or aluminum.

- Best suited for high-power applications where rigidity is not a concern.

- Commonly used in heavy-duty vehicles and industrial-grade systems.

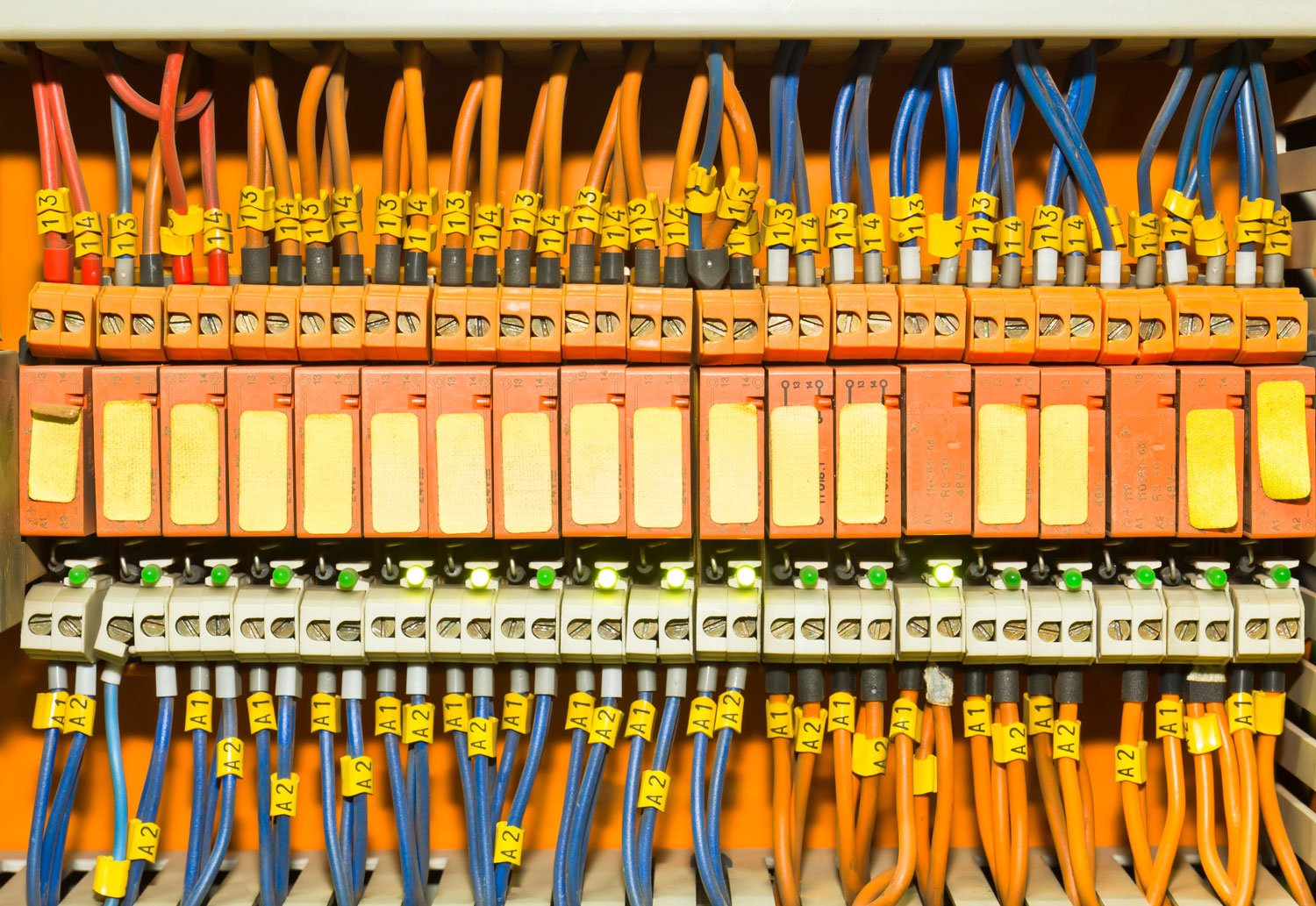

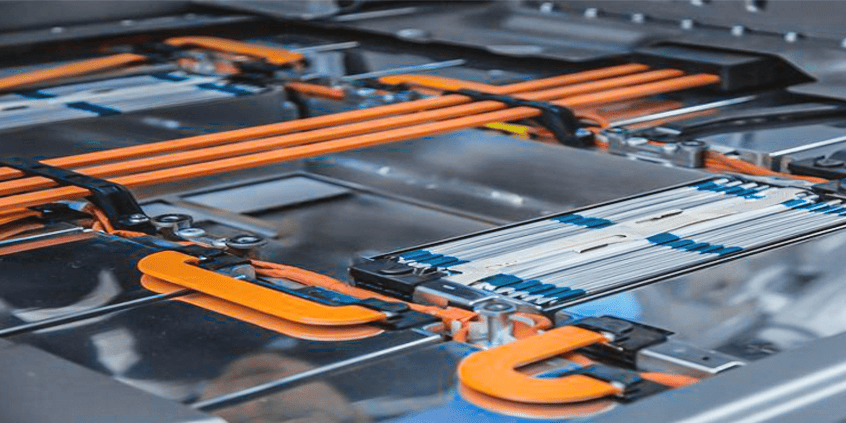

b. Laminated Bus Bars

- Composed of multiple conductive layers separated by insulation.

- Minimize inductance and electromagnetic interference (EMI), making them ideal for high-frequency applications.

- Often found in electric and hybrid vehicles where performance and compactness are critical.

c. Flexible Bus Bars

- Constructed using thin layers of conductive material, allowing flexibility.

- Designed to accommodate vibrations and movements in vehicles, reducing the risk of connection failures.

- Widely used in dynamic automotive systems and tight spaces.

d. Custom Bus Bars

- Tailored to specific automotive designs and requirements.

- Frequently used in electric and hybrid vehicles to meet unique power distribution challenges.

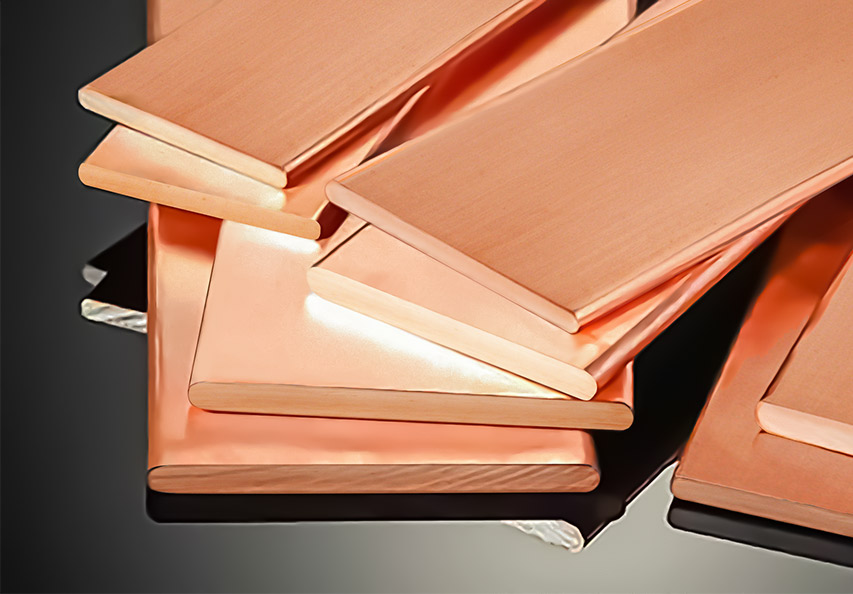

Materials Used in Automotive Electrical Bus Bars

The choice of material significantly influences the performance, cost, and durability of an automotive electrical bus bar.

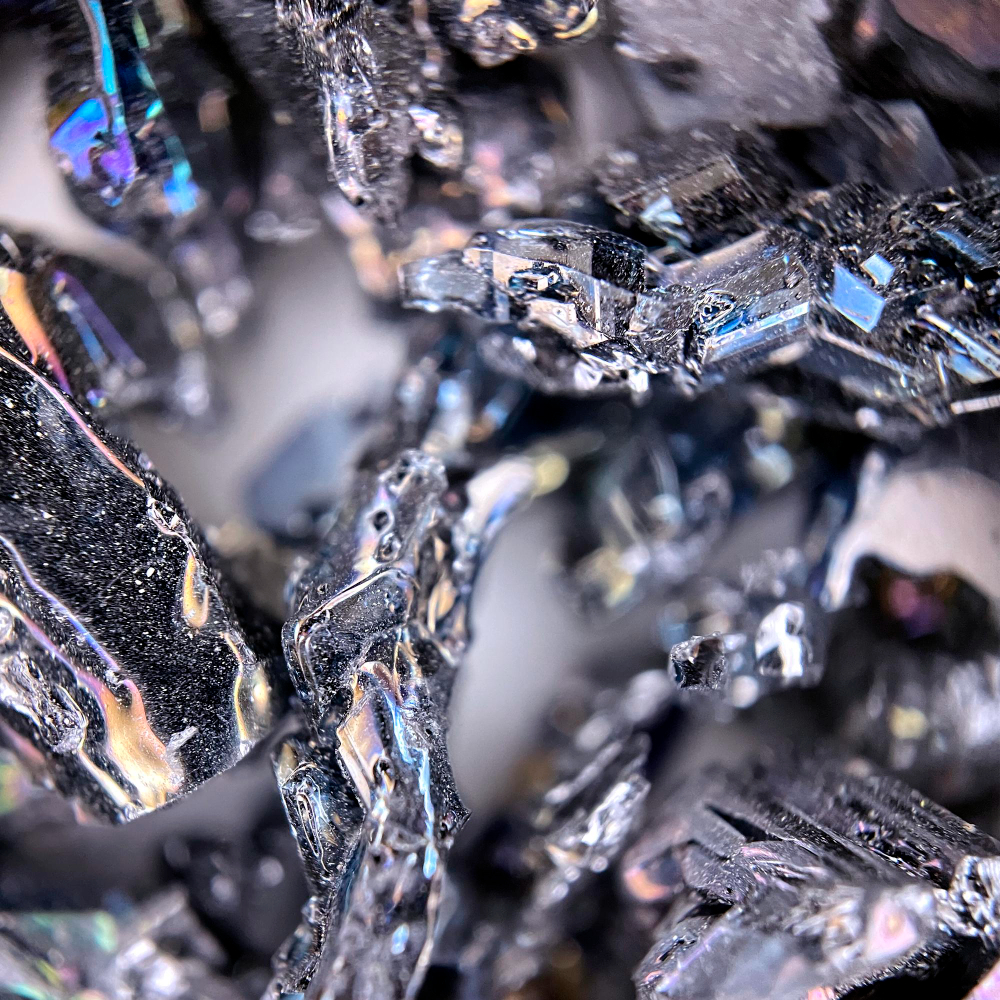

a. Copper

- Advantages: High electrical conductivity, excellent heat dissipation, and durability.

- Applications: High-performance vehicles, where efficiency is paramount.

b. Aluminum

- Advantages: Lightweight, cost-effective, and resistant to corrosion.

- Applications: Standard passenger vehicles, where weight reduction is a priority.

c. Silver-Plated Copper

- Advantages: Combines copper’s conductivity with silver’s corrosion resistance.

- Applications: Harsh environments, such as off-road vehicles and industrial applications.

d. Composite Materials

Emerging materials like carbon-reinforced polymers are being explored for their lightweight and sustainable properties.

Advantages of Using Automotive Electrical Bus Bars

a. Efficiency

Bus bars streamline power distribution, reducing the energy losses associated with traditional wiring systems.

b. Space Optimization

By consolidating multiple connections, bus bars reduce the space required for wiring, making them ideal for compact vehicle designs.

c. Durability and Reliability

Bus bars are engineered to withstand extreme conditions, including high temperatures, vibrations, and mechanical stress.

d. Safety

Insulated bus bars minimize the risk of electrical hazards such as short circuits, arcing, and fire.

e. Simplified Maintenance

The organized layout of bus bars makes it easier to diagnose and repair electrical issues.

Applications of Automotive Electrical Bus Bars

Bus bars are indispensable in various automotive systems, including:

a. Internal Combustion Engine (ICE) Vehicles

Manage power for ignition systems, lights, and climate control.

Enhance efficiency in power distribution to auxiliary systems.

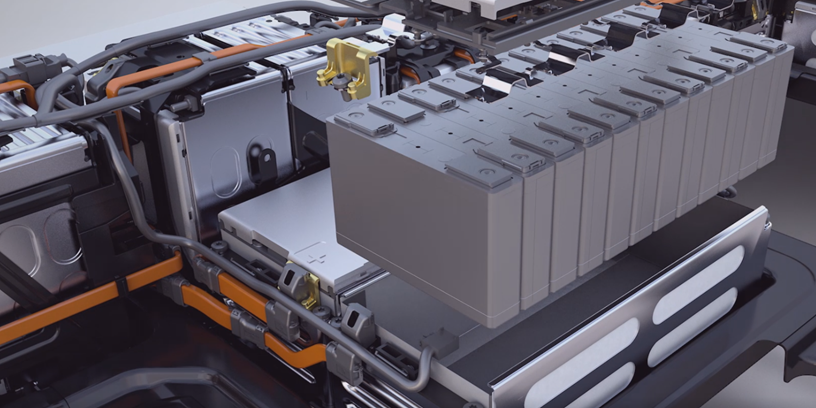

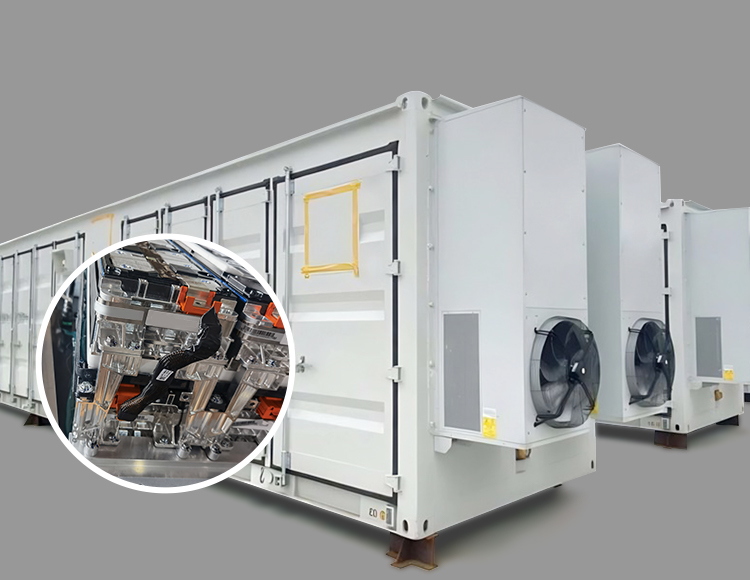

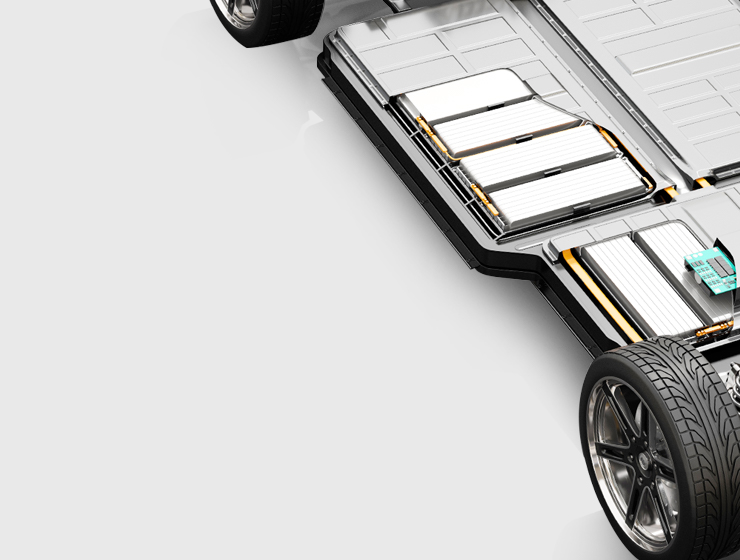

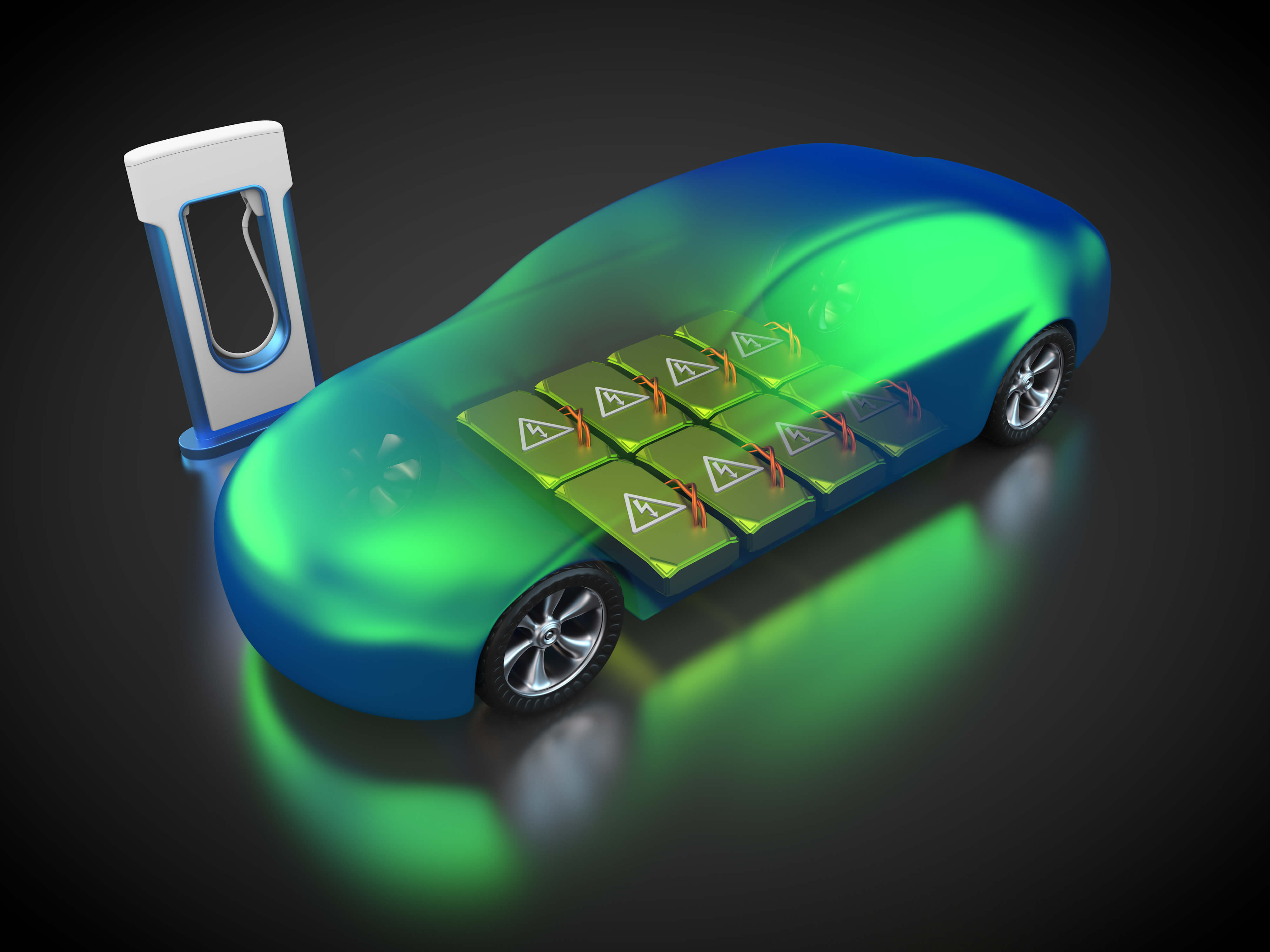

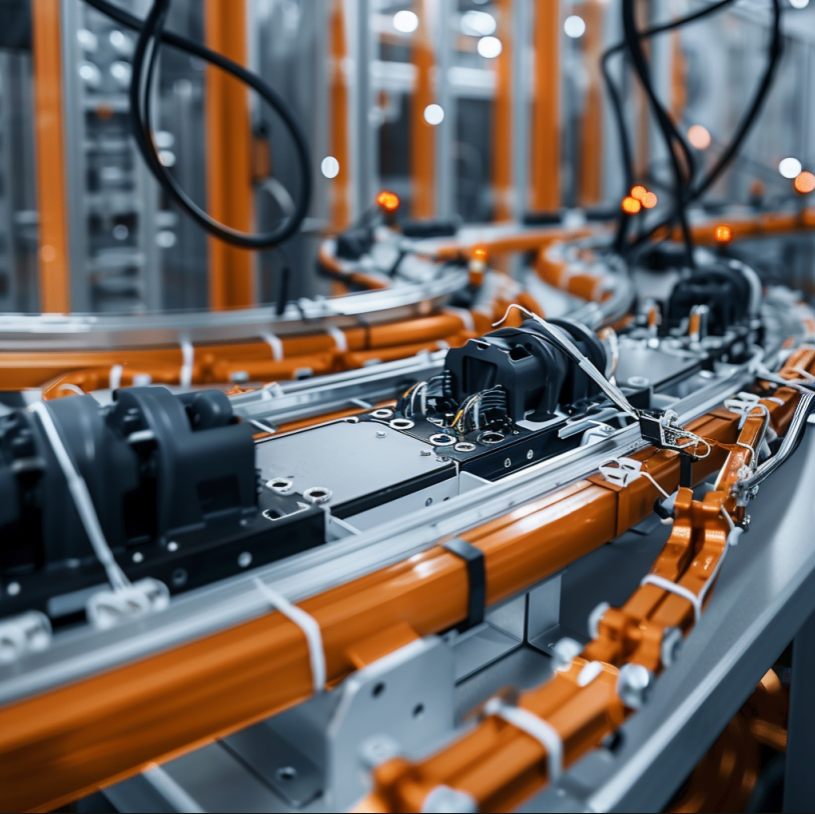

b. Electric Vehicles (EVs)

Connect high-voltage batteries to inverters and motors.

Enable efficient power management in ultra-fast charging systems.

c. Hybrid Electric Vehicles (HEVs)

Integrate power from electric motors and combustion engines seamlessly.

Provide efficient energy flow in regenerative braking systems.

d. Heavy-Duty Vehicles

Handle high currents required by trucks, buses, and construction equipment.

Ensure reliability in harsh operating conditions.

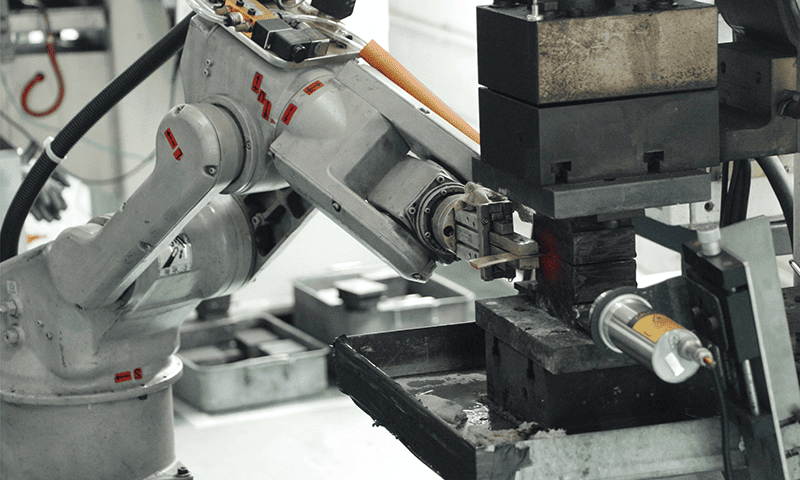

Manufacturing and Design Considerations

The design of an automotive electrical bus bar must account for:

a. Current Carrying Capacity

Bus bars should handle the maximum current without overheating or causing voltage drops.

b. Thermal Management

Proper heat dissipation is critical to maintaining performance and safety.

c. Insulation and Coating

Insulated designs prevent electrical shorts and improve resistance to environmental factors.

d. Customization

Custom designs cater to unique automotive applications, optimizing performance and compatibility.

Challenges in Automotive Electrical Bus Bar Implementation

Despite their advantages, bus bars come with certain challenges:

a. Initial Costs

The materials and manufacturing processes for bus bars can be more expensive than traditional wiring.

b. Weight Optimization

Balancing conductivity and weight requires careful material selection and design.

c. Integration with Modern Systems

Advanced automotive systems like autonomous driving technologies demand precise and innovative bus bar designs.

d. Environmental Factors

Bus bars must be designed to resist moisture, corrosion, and extreme temperatures.

The Future of Automotive Electrical Bus Bars

As the automotive industry transitions to electric and autonomous vehicles, the role of automotive electrical bus bars is expanding.

a. High-Voltage Systems

Future bus bars will need to handle ultra-fast charging and high-voltage applications.

b. Sustainable Materials

Eco-friendly and recyclable materials are becoming a priority for manufacturers.

c. Miniaturization

Compact designs will support the integration of more features in smaller vehicle spaces.

d. Smart Bus Bars

Embedded sensors and monitoring systems may enable real-time diagnostics and predictive maintenance.

How to Select the Right Automotive Electrical Bus Bar

Choosing the right bus bar involves:

a. Evaluating Electrical Requirements

Consider the voltage, current, and power demands of your system.

b. Assessing Environmental Conditions

Factor in temperature, moisture, and exposure to corrosive substances.

c. Consulting Experts

Work with experienced manufacturers to design and select the ideal solution.

Maintenance and Troubleshooting

Regular maintenance ensures the longevity and performance of an automotive electrical bus bar:

Inspect for Damage

Look for signs of corrosion, wear, or physical damage.

Monitor Performance

Check for overheating or unusual electrical behavior.

Replace Worn Components

Damaged or worn bus bars should be replaced promptly to prevent failures.

Conclusion

The automotive electrical bus bar is a critical component in modern vehicles, offering unparalleled efficiency, reliability, and safety. With advancements in electric and autonomous vehicles, bus bar technology continues to evolve, promising a future of improved performance and sustainability.

Whether you’re designing a vehicle or upgrading its electrical system, understanding the nuances of bus bars will help you make informed decisions that enhance functionality and longevity.