Choosing the Right Insulated Busbar for Your Electrical Project: A Buyer's Guide

When it comes to designing and implementing electrical systems, selecting the right components is crucial for efficiency, safety, and performance. One of the key components that often requires careful consideration is the insulated busbar. This guide aims to provide you with an in-depth understanding of insulated busbars, including their types, applications, advantages, and crucial factors to consider when making your choice. By the end of this guide, you will have the knowledge necessary to select the most suitable insulated busbar for your electrical project.

What is an Electrical Busbar?

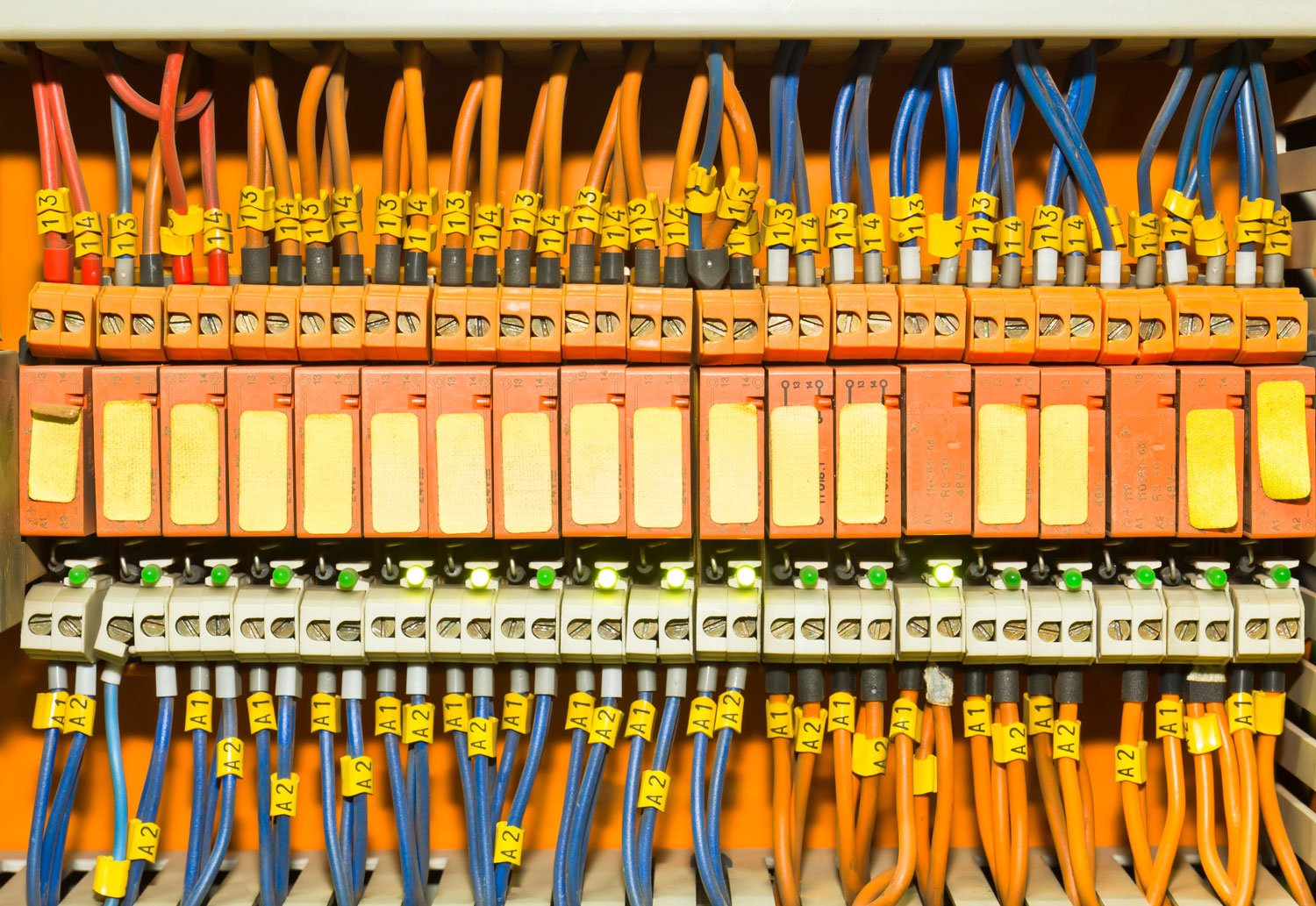

An electrical busbar is a crucial component in power distribution systems, functioning as a conductive material that acts as a central hub for distributing electrical power to various circuits. Typically constructed from highly conductive materials like copper or aluminium, electrical busbars are designed to facilitate the efficient transfer of electricity while minimizing resistance and heat generation. This efficiency is particularly important in high-load applications, where excessive heat can lead to energy losses and potential safety hazards.

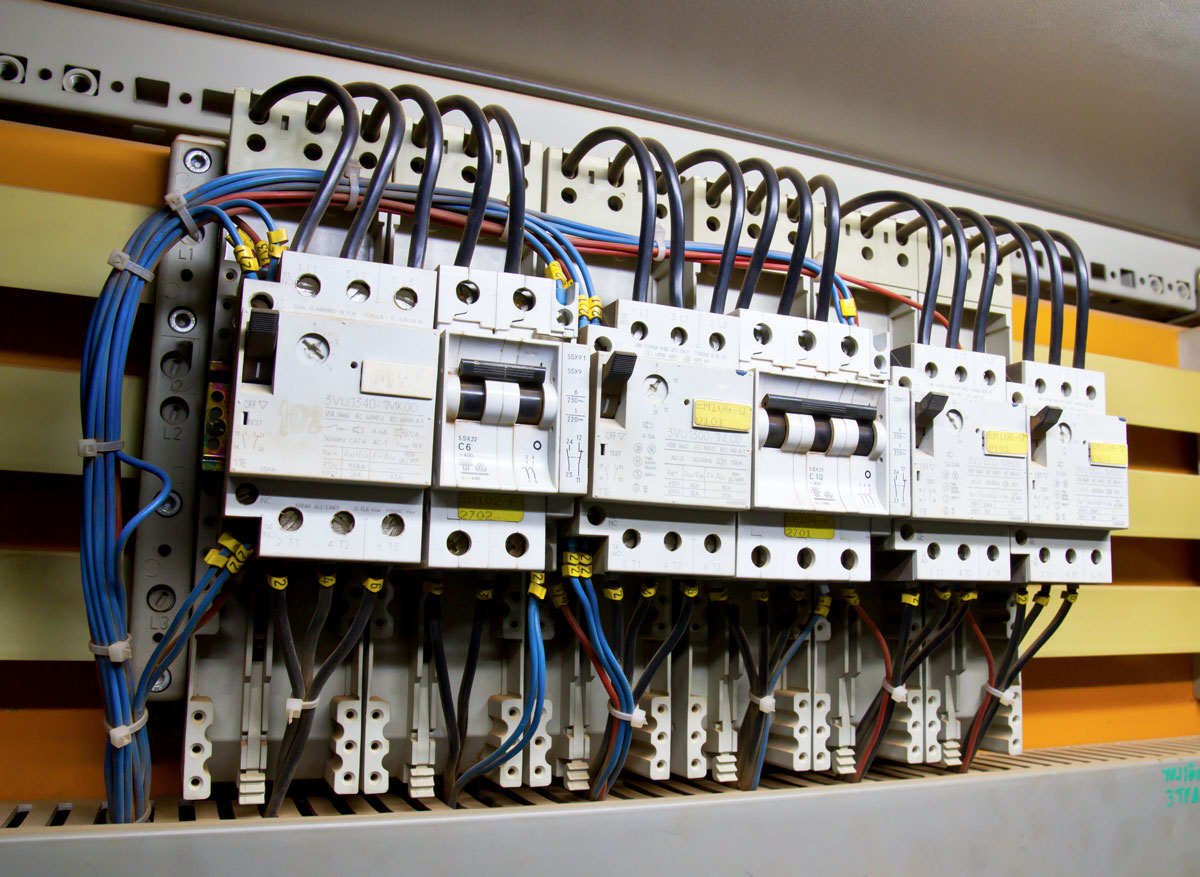

Electrical busbars are commonly employed in a variety of settings, including electrical panels, switchgear, and substations, where they provide a robust framework for connecting multiple circuits and accommodating diverse electrical loads. Their ability to handle high currents makes them indispensable in both commercial and industrial environments. Additionally, electrical busbars can be configured in various shapes and sizes, allowing for flexibility in design and installation to meet specific project requirements. Overall, they play a vital role in ensuring reliable and safe electrical distribution.

Types of Busbars

Busbars come in various forms, each tailored to meet specific electrical applications and requirements. Understanding the different types can help you choose the most suitable option for your project.

- Bare Busbars: These are uncoated conductors that serve as straightforward solutions for direct connections in environments where insulation is not a concern. Bare busbars are typically utilized in settings such as substations and electrical panels, where they can be securely mounted and shielded from accidental contact. While they offer excellent conductivity, their use is often limited to areas where safety risks are mitigated through careful design and implementation.

- Insulated Busbars: Designed with safety as a top priority, insulated busbars are coated or encased in insulating materials to prevent accidental contact. This insulation significantly reduces the risk of electrical shocks and short circuits, making them ideal for environments where personnel may come into close proximity to electrical components. Insulated busbars also optimize space efficiency, as they can be compactly designed to fit into smaller installations without compromising safety.

- Flexible Busbars: Composed of multiple thin conductors, flexible busbars offer unique advantages in terms of adaptability. Their design allows them to be bent and shaped to fit various configurations, making them particularly useful in tight or irregular spaces. This flexibility is beneficial in applications where conventional busbars might not fit, such as in complex machinery or crowded electrical panels.

- Busway Systems: These are enclosed busbars that provide a modular approach to power distribution. Ideal for large commercial and industrial facilities, busway systems allow for easy scalability and reconfiguration as power demands change. They can accommodate high current loads while maintaining safety and efficiency, making them a preferred choice for environments requiring flexible and reliable electrical distribution.

The Importance of Insulation

The insulation on a busbar plays several critical roles that enhance both safety and performance in electrical systems.

- Safety is perhaps the most crucial function of insulation. It effectively prevents accidental contact with live conductors, significantly reducing the risk of electrical shocks and potential fires. This safety feature is especially important in environments where personnel work closely with electrical equipment, providing an essential barrier between users and hazardous voltages.

- Protection is another vital aspect. Insulated busbars are designed to resist degradation from environmental factors such as moisture, dust, and chemical exposure. These protective qualities ensure that the busbars maintain their performance over time, extending their lifespan and reliability in various applications.

- Efficiency: insulation contributes to efficiency by minimizing energy losses due to leakage currents. This is particularly important in high-power applications, where even small losses can translate into significant energy waste and increased operational costs.

- Space management is enhanced with insulated busbars, which can be more compact compared to their bare counterparts. This compact design allows for more efficient use of space in electrical installations, making it easier to organize and maintain systems without sacrificing performance or safety. Overall, the insulation on busbars is essential for ensuring optimal operation in diverse electrical environments.

Key Considerations When Choosing an Insulated Busbar

Selecting the right insulated busbar involves considering several key factors:

1. Material Selection

The choice of material for your insulated busbar is essential. Copper and aluminum are the most common materials used due to their excellent conductivity. Copper is preferred for applications requiring high conductivity and strength, while aluminum is lighter and less expensive, making it suitable for large-scale installations where weight is a concern.

2. Current Rating

Ensure that the insulated busbar you choose can handle the expected load. Current ratings are typically specified in amperes (A) and should be chosen based on the maximum load your electrical system will experience.

3. Temperature Rating

Busbars are subject to thermal stress due to the current passing through them. It’s crucial to select an insulated busbar with a temperature rating that accommodates the ambient conditions of your installation environment. Check the manufacturer's specifications for operating temperature limits.

4. Insulation Type

The type of insulation used can greatly impact the performance and safety of the busbar. Common insulation materials include:

- PVC (Polyvinyl Chloride): Cost-effective and widely used, suitable for low-temperature applications.

- XLPE (Cross-Linked Polyethylene): Offers better thermal performance and is suitable for high-temperature environments.

- Rubber: Provides flexibility and excellent resistance to environmental factors.

5. Size and Configuration

Consider the physical dimensions of the insulated busbar, including its height, width, and thickness. The busbar should fit well within your electrical cabinet or enclosure, allowing for easy installation and maintenance. Additionally, the configuration—such as straight, L-shaped, or T-shaped—should align with your layout requirements.

6. Environmental Considerations

Evaluate the environmental conditions where the insulated busbar will be installed. Factors such as humidity, temperature fluctuations, exposure to chemicals, and potential mechanical stress can influence your choice. Ensure that the selected busbar is rated for these conditions to guarantee durability.

7. Regulatory Compliance

Electrical installations are subject to various codes and standards. Ensure that your insulated busbar complies with relevant electrical safety standards, such as those set by the National Electrical Manufacturers Association (NEMA) or the International Electrotechnical Commission (IEC).

Advantages of Using Insulated Busbars

Choosing insulated busbars offers several benefits that enhance the performance and safety of your electrical system:

- Improved Safety: The primary advantage of using insulated busbars is the increased safety they provide, minimizing the risk of electrical accidents.

- Space Efficiency: Insulated busbars can save valuable space in electrical installations, allowing for more compact designs.

- Reduced Maintenance Costs: Insulation helps protect the busbars from environmental damage, reducing the frequency and costs of maintenance.

- Enhanced Performance: With lower energy losses due to insulation, the overall efficiency of the electrical system can be improved.

- Flexibility: Insulated busbars can be designed to accommodate various configurations, making them versatile for different projects.

Applications of Insulated Busbars

Insulated busbars are used in a variety of applications across different industries, including:

- Power Distribution: Essential in substations and electrical panels for distributing electricity safely and efficiently.

- Data Centers: Used to connect multiple server racks and power supplies while ensuring safe operation in high-density environments.

- Industrial Automation: Employed in factories and manufacturing plants for powering machinery and equipment.

- Renewable Energy Systems: Used in solar and wind energy applications to connect various components of the energy system.

Conclusion

Choosing the right insulated busbar is critical for the safety, efficiency, and performance of your electrical project. By considering the factors outlined in this guide—such as material, current rating, temperature rating, insulation type, and environmental conditions—you can make an informed decision that meets your project’s requirements.

Whether you're working on a small-scale installation or a large industrial application, the right insulated busbar will ensure that your electrical system operates safely and efficiently. Always consult with manufacturers and electrical engineers to confirm that your selected insulated busbar complies with relevant standards and is suited to your specific needs.

In summary, insulated busbars represent an essential component in modern electrical systems, providing a safe and efficient means of power distribution. Investing time in understanding their characteristics and applications will yield significant benefits in the long run, ensuring a successful and safe electrical project.