Leading Busbar Manufacturer

RHI, founded in 2011, is a leading Chinese manufacturer and exporter of flexible and rigid busbars. With over a decade of expertise, the company operates a 30,000㎡ facility. As a Tier 1 supplier, RHI serves major clients such as CATL, the Renault-Nissan Alliance, and Trina Solar, offering tailored solutions and advanced technical support.

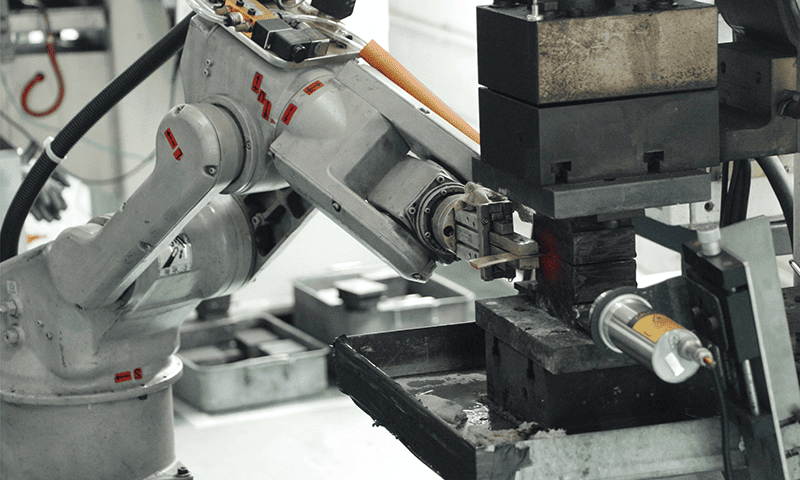

Equipped with fully automated production lines, six-axis robotic workshops, a precision mold processing center, and quality inspection facilities, RHI ensures efficient production control.

Our company follows IATF 16949, ISO 14001, and ISO 45001 standards, with all products meeting RoHS, REACH, and UL 94V-0 requirements. Adherence to ISO 9001 guarantees consistent, high-quality products.

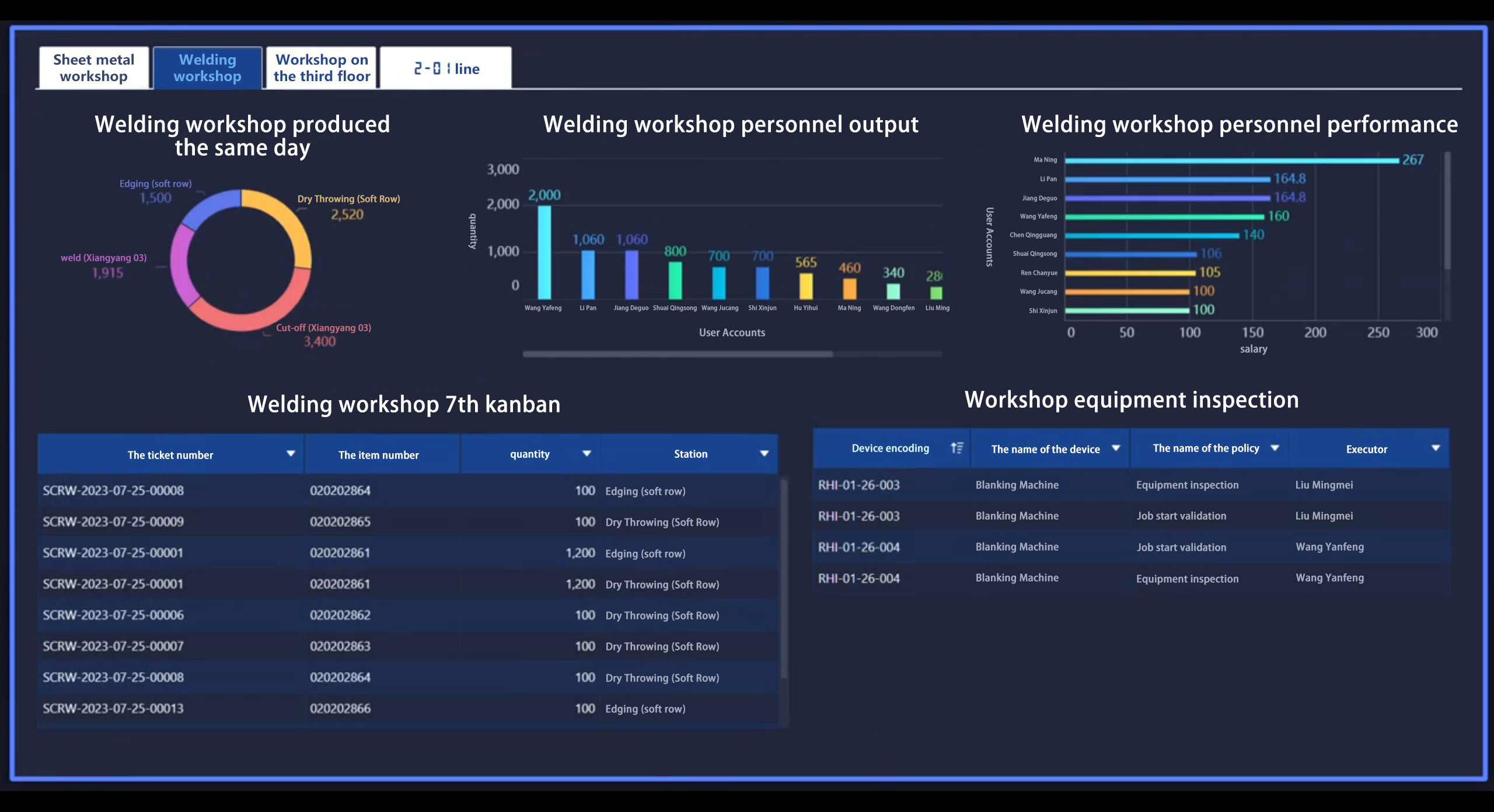

Digital Transformation Upgrade

RHI is undergoing a digital transformation by adopting ERP, PLM, and MES systems to improve busbar manufacturing efficiency and management, meeting the complex demands of the new energy industry. These systems provide full operational visibility, enabling quick market responses and delivering significant advantages. The PLM system ensures compliance with industry standards through material standardization and design data management, speeding up time-to-market and reducing risks.

The MES system improves production transparency with real-time equipment data and full quality traceability, enhancing reliability and efficiency. This integration has upgraded RHI's manufacturing processes, offering customers efficient and reliable products with real value.

Robust Manufacturing Capabilities

RHI operates a 30,000-square-meter facility with multiple automated production lines, producing over 100 sets of molds and 200+ tooling gauges monthly. We employ CCD automated inspection and a rigorous three-stage quality control process—initial, in-process, and final. Our standardized, consistent-quality products have earned inspection exemptions from multiple OEMs.

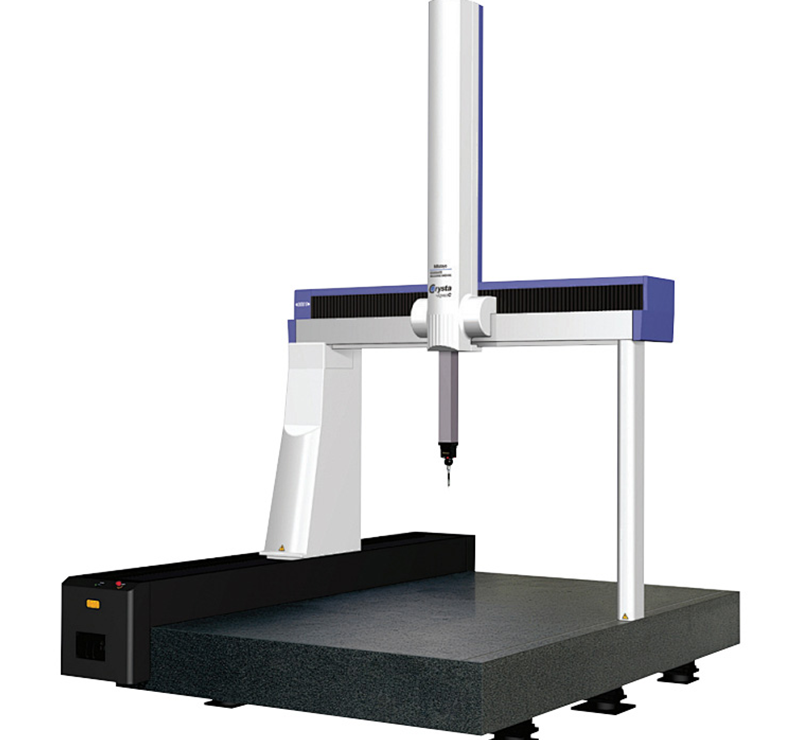

Utilizing advanced technologies like 3D design, electro-thermal simulation, and mold flow analysis, RHI Electric optimizes busbar product design and performance. Our laboratory is equipped with various testing devices for salt spray, hardness, pull-off strength, contact resistance, and bending capability. With these manufacturing capabilities, RHI Electric delivers efficient and reliable power connection solutions to clients in the new energy sector.

Precision Testing Equipment

RHI's laboratory is equipped with advanced devices, including a salt spray tester, metallographic analyzer, and constant temperature and humidity chamber. These enable testing of salt spray corrosion, hardness, pull-out force, contact resistance, and bending performance, ensuring our products meet industry quality standards in design and production.