ALUMINIUM BUSBAR

RHI - Professional Aluminium Busbar Supplier & Manufacturer

Detailed Characteristics of Aluminium Busbar

Aluminium busbars are conductive components made primarily of aluminium or aluminium alloys, widely used in power transmission, distribution equipment, rail transit, new energy, and industrial manufacturing. Their excellent physical, chemical, and mechanical properties make them essential in modern electrical engineering

Lightweight

- Aluminium is only 1/3 the density of copper, making aluminium busbars significantly lighter while maintaining the same current-carrying capacity.

- This reduces the overall weight of equipment, which is crucial in aerospace, rail transit, and automotive industries, improving energy efficiency.

- Transportation and installation are easier and more cost-effective due to reduced material weight.

Excellent Electrical Conductivity

- Although aluminium's conductivity (35~61% IACS) is lower than copper (100% IACS), increasing the cross-sectional area can achieve comparable electrical performance while reducing costs.

- High-purity aluminium (such as 1350-grade aluminium) provides excellent conductivity, making it suitable for high-current transmission.

- In applications like power distribution and data centers, aluminium busbars offer an efficient and cost-effective alternative to copper busbars.

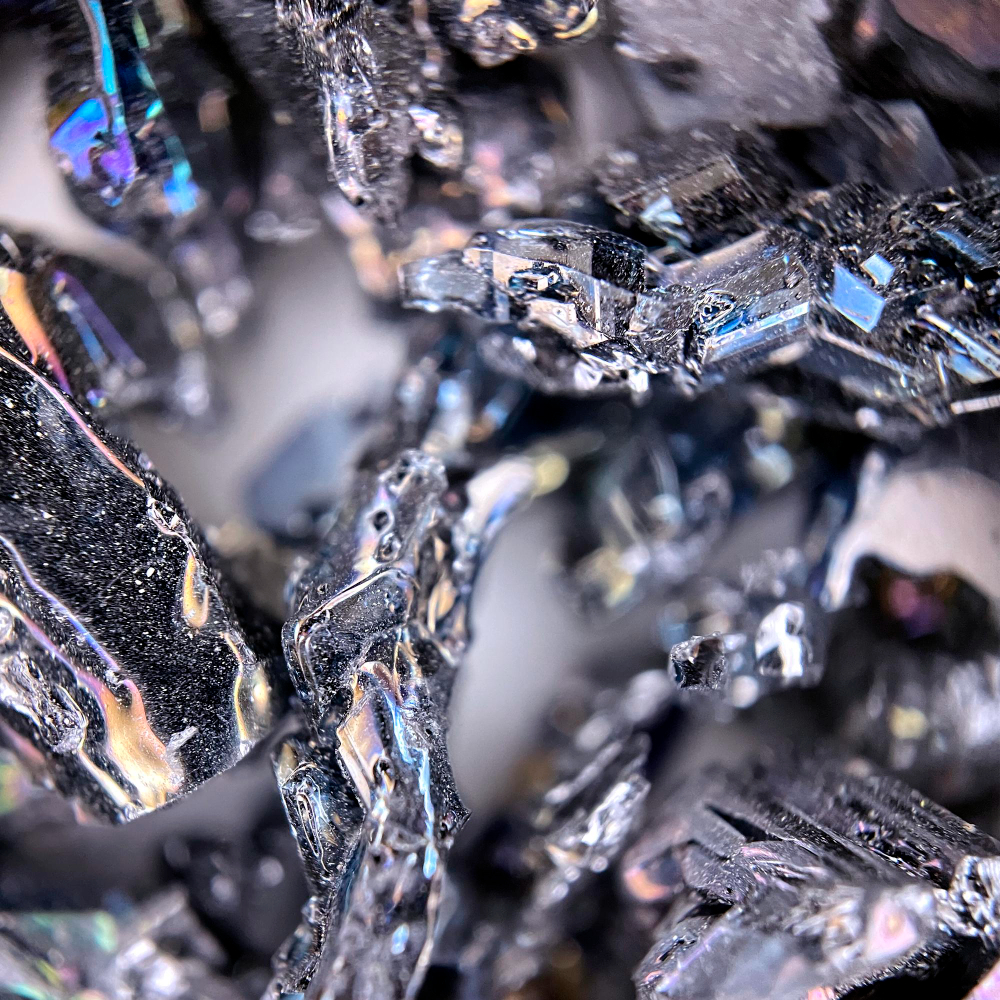

Superior Corrosion Resistance

- Aluminium naturally forms a dense oxide layer (Al₂O₃) on its surface, preventing further oxidation and corrosion.

- Suitable for humid and high-salinity environments, such as coastal power transmission systems and renewable energy installations like wind and solar farms.

- Additional anodizing treatment can enhance corrosion resistance, making aluminium busbars even more durable in harsh conditions.

Efficient Heat Dissipation

- Aluminium has a thermal conductivity of approximately 235 W/m·K, slightly lower than copper’s 400 W/m·K, but still offers excellent heat dissipation.

- Its high surface-area-to-volume ratio allows for faster cooling and reduced temperature rise, ensuring the safety and stability of power equipment.

- This is particularly beneficial for high-power electronic devices such as data centers, industrial power systems, and renewable energy inverters.

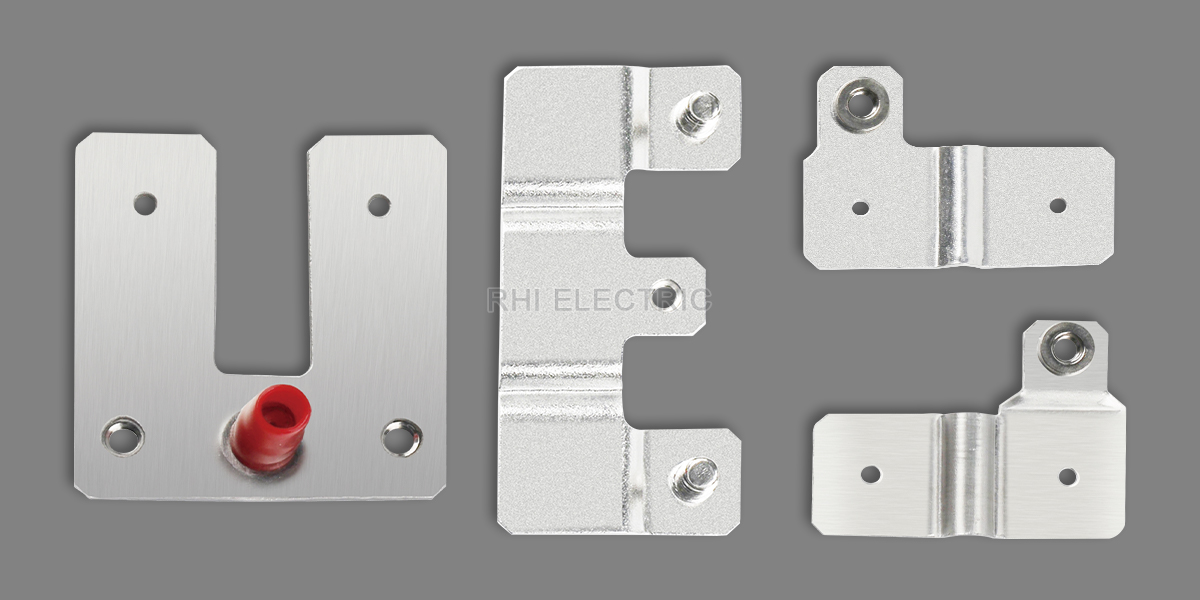

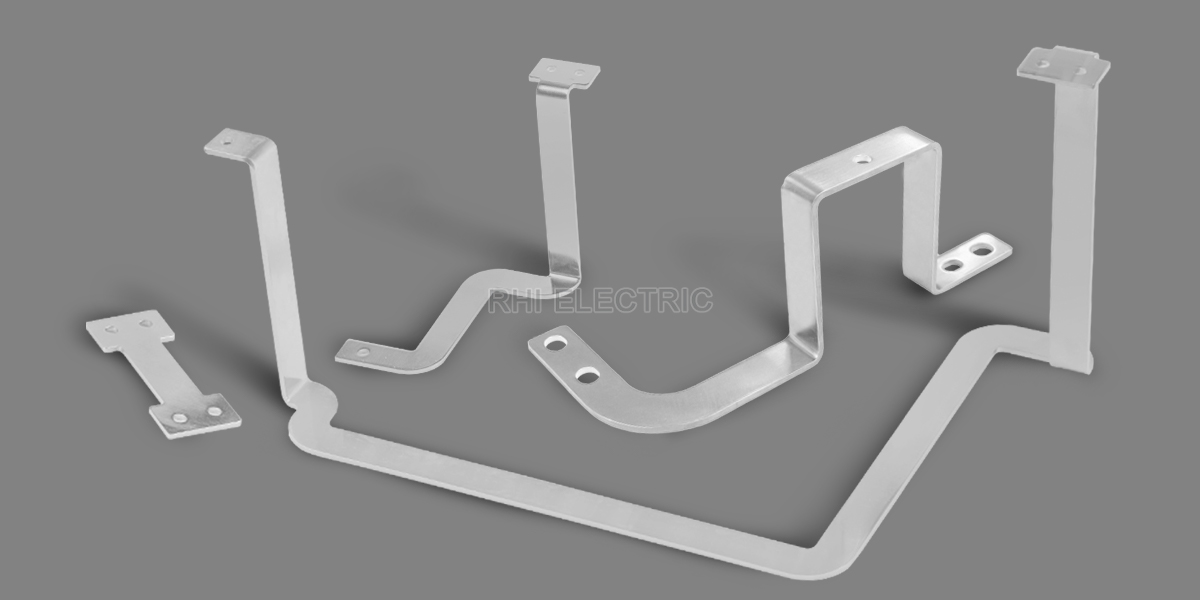

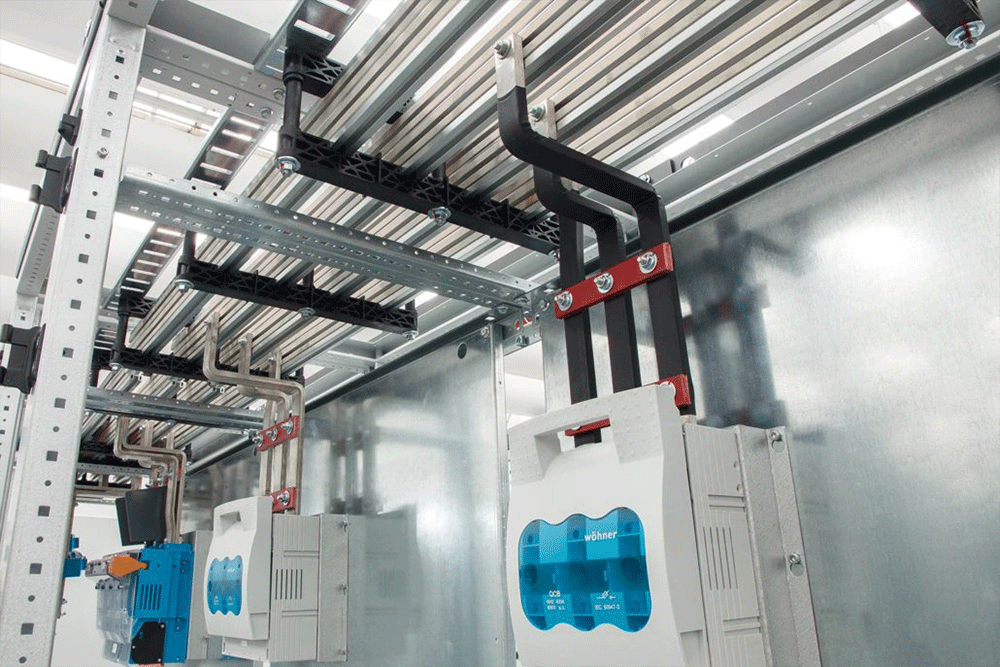

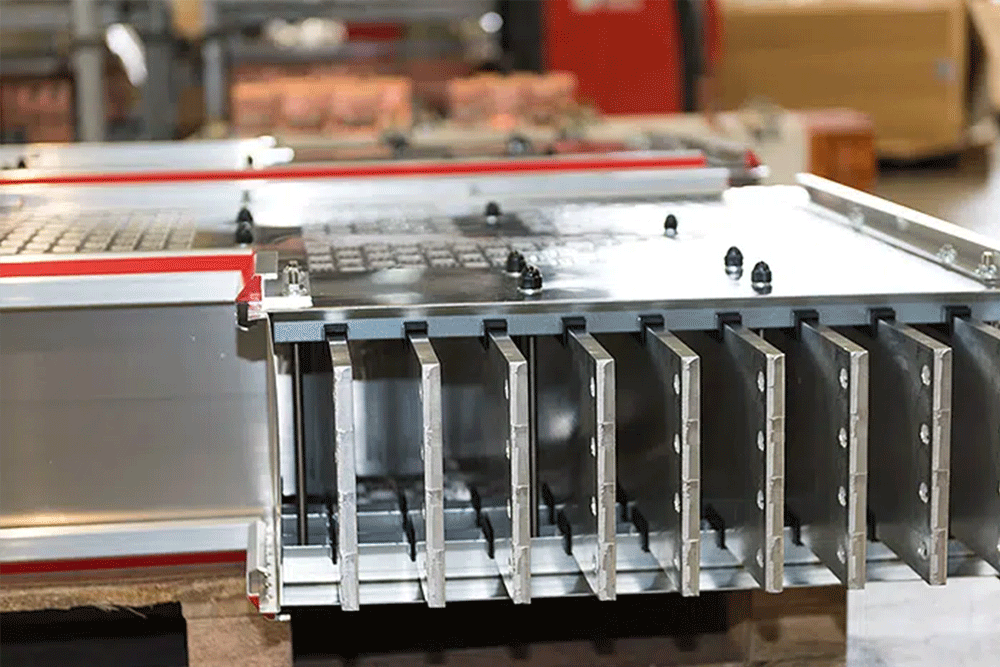

Excellent Workability

- Easily cut, punched, bent, drilled, and welded, making it highly customizable for different electrical equipment needs.

- Suitable for extrusion, rolling, drawing, and casting, allowing the production of various aluminium busbar shapes, including solid, hollow, and multi-layer busbars.

- Commonly used in switchgear, battery connection busbars, and busway systems, offering flexibility in design and manufacturing.

Eco-Friendly & Sustainable

- Aluminium is 100% recyclable, with a high recycling rate, contributing to sustainability and reducing environmental impact.

- Aluminium production requires less energy compared to copper, aligning with global trends towards green energy solutions such as solar farms and wind power stations.

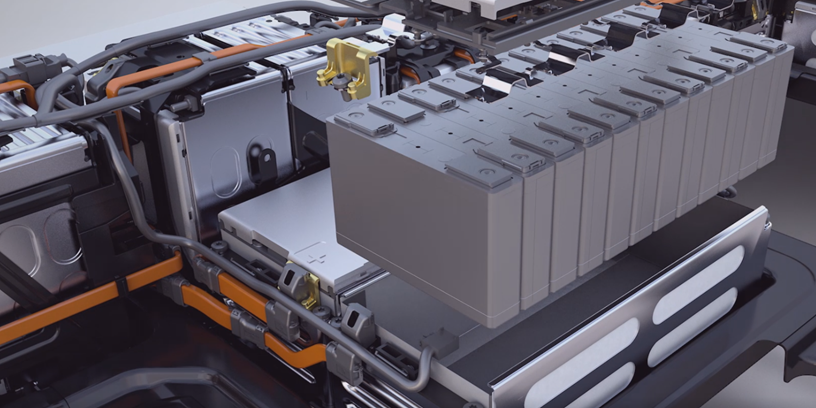

- The use of aluminium busbars in electric vehicles (EVs) and renewable energy applications supports energy efficiency and environmental protection efforts.

Cost-Effective Solution

- Aluminium is significantly cheaper than copper, typically costing 30% - 50% less, making it an economical alternative.

- Suitable for large-scale power transmission projects, data centers, rail transit, and electric vehicles, where cost efficiency is critical.

- Lower installation and maintenance costs, as aluminium’s lightweight nature makes transportation and assembly easier.

Mechanical Strength & Durability

- The mechanical strength of aluminium busbars can be enhanced through alloying (such as 6061, 6101 aluminium alloys), improving wear resistance and durability.

- Aluminium busbars maintain good mechanical stability under high-current surges and vibration, reducing the risk of mechanical failure.

- Widely used in industrial busway systems, power transformers, and battery connection busbars, where long-term durability is required.

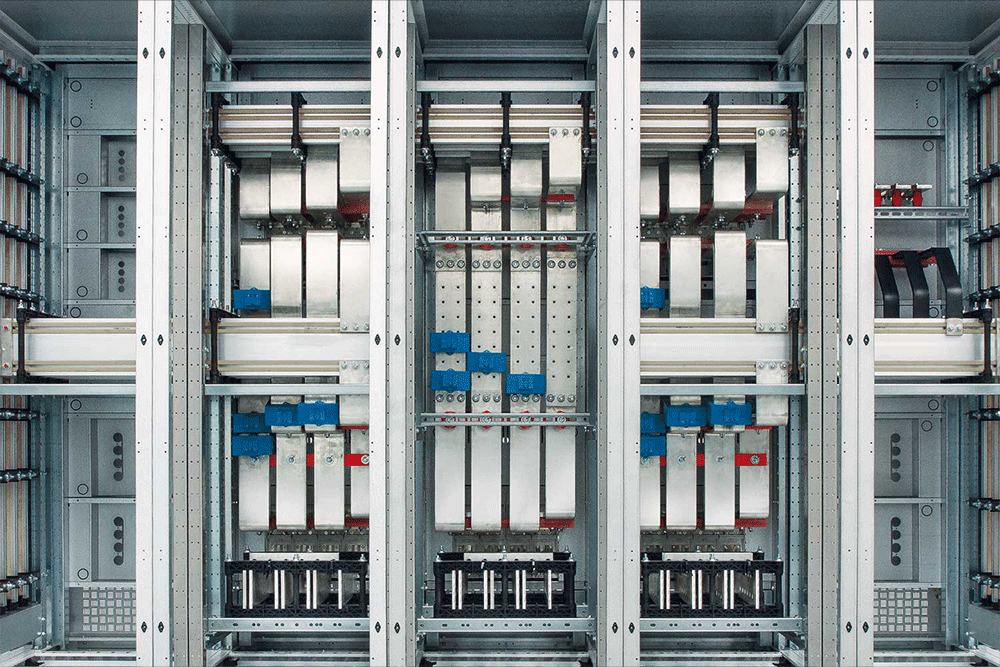

Wide Range of Applications

Due to its excellent physical and chemical properties, aluminium busbars are widely used across multiple industries, including:

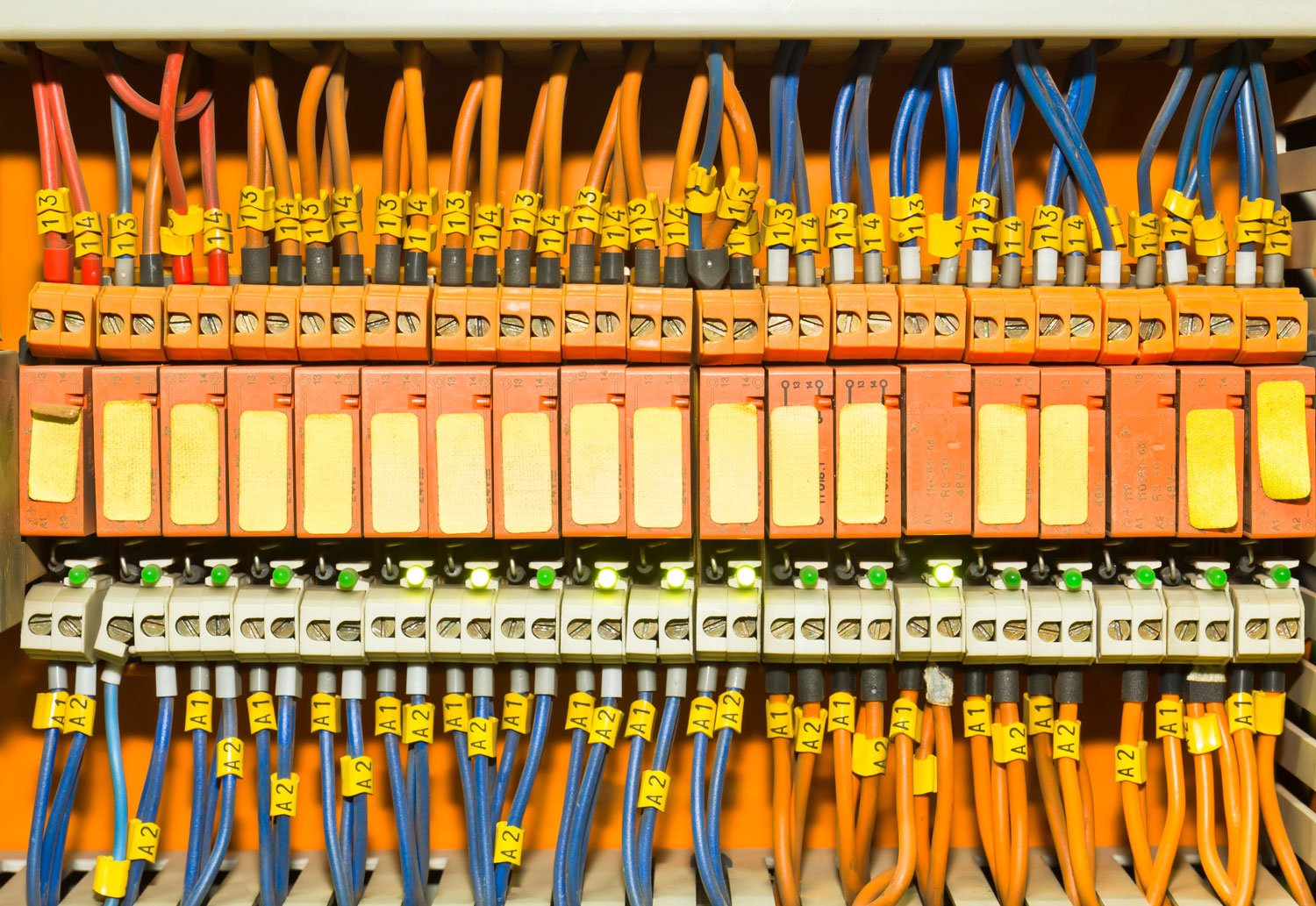

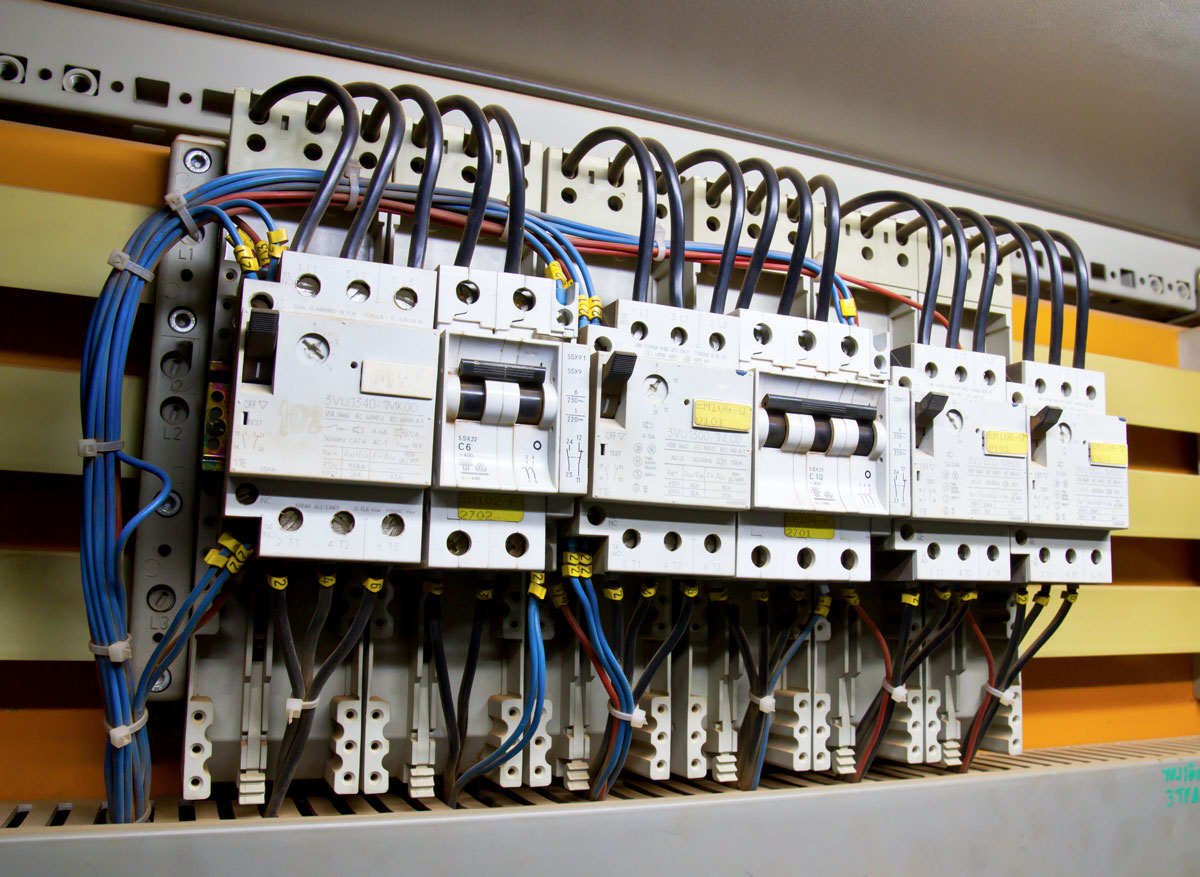

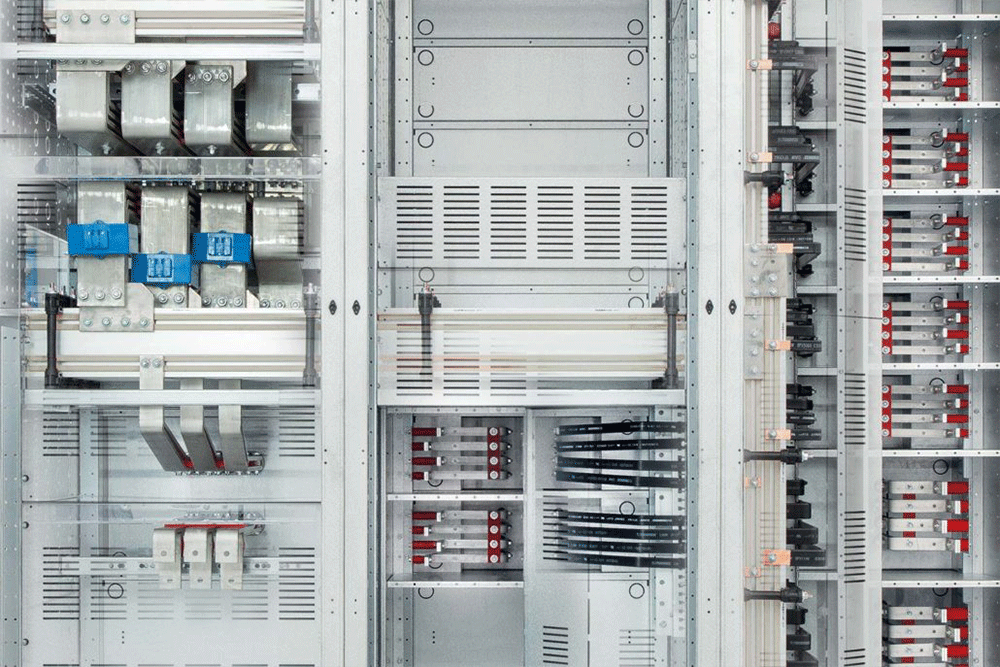

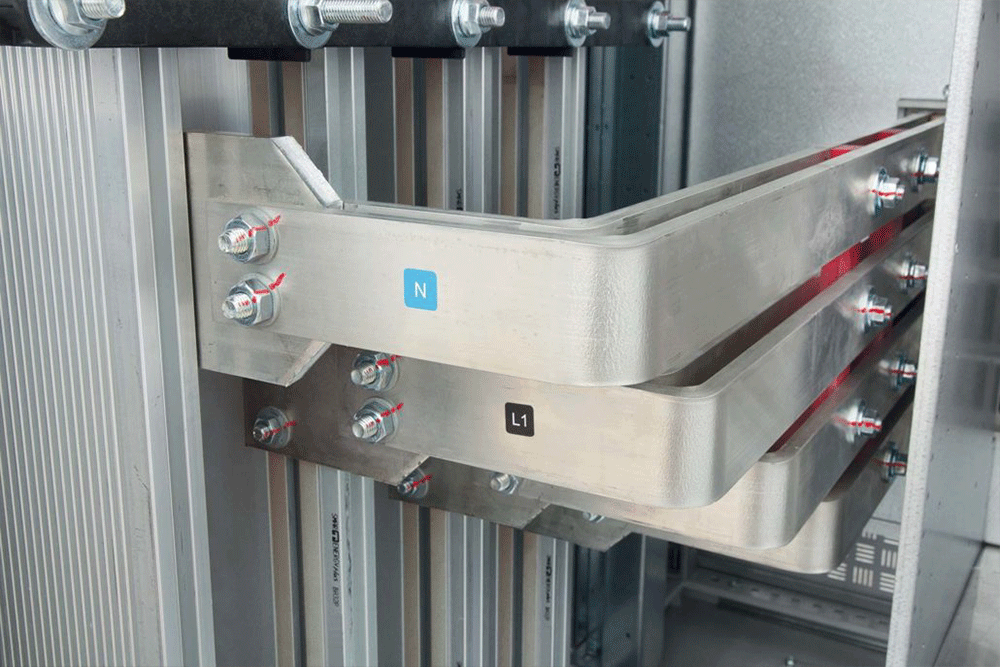

✅ Power Transmission & Distribution

- Substations, high and low voltage switchgear, busway systems, power transformers

✅ Rail Transit - Metro systems, high-speed rail power supply, locomotive busbar connections

✅ New Energy Vehicles (EVs) - Battery connection busbars, motor control systems

✅ Data Centers - Server power systems, large UPS power networks

✅ Renewable Energy - Solar power plants, wind energy systems, energy storage solutions

✅ Industrial Applications - Industrial automation equipment, large-scale machinery electrical connections

Conclusion

Aluminium busbars offer lightweight design, excellent electrical conductivity, superior corrosion resistance, efficient heat dissipation, and cost-effectiveness, making them an ideal alternative to copper busbars in modern electrical systems. Their versatility, sustainability, and affordability make them a preferred choice across various industries.

As a professional aluminium busbar supplier, RHI provides high-quality, customized aluminium busbar solutions to enhance electrical system efficiency and reliability. Contact us for more details or custom requirements!