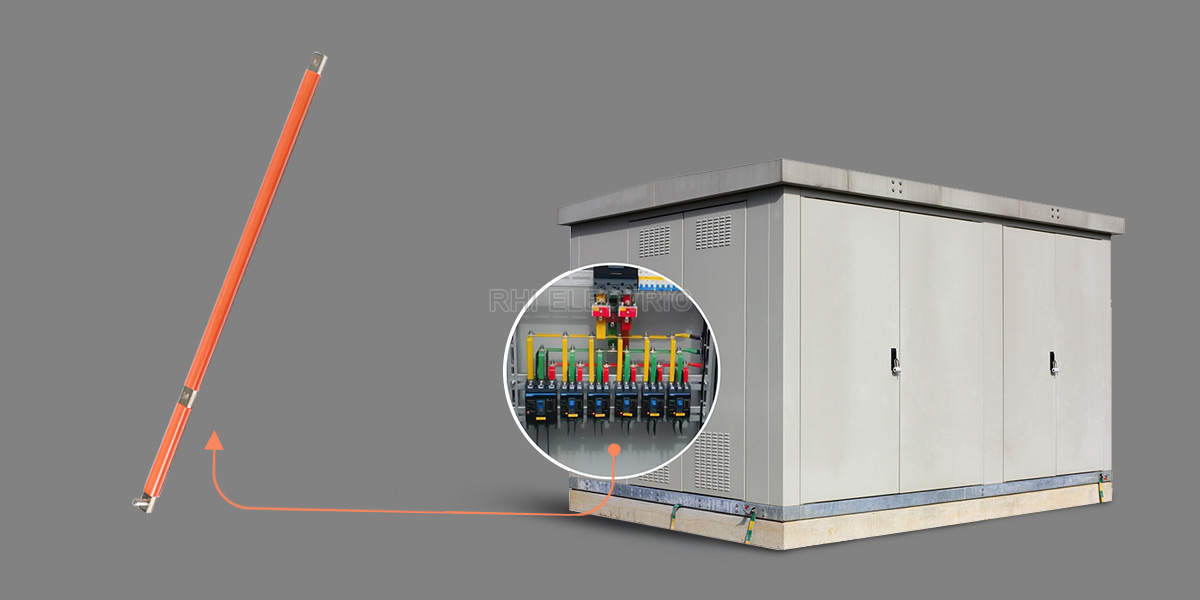

Rigid Aluminium Busbars with PVC Insulation for Panel Boards

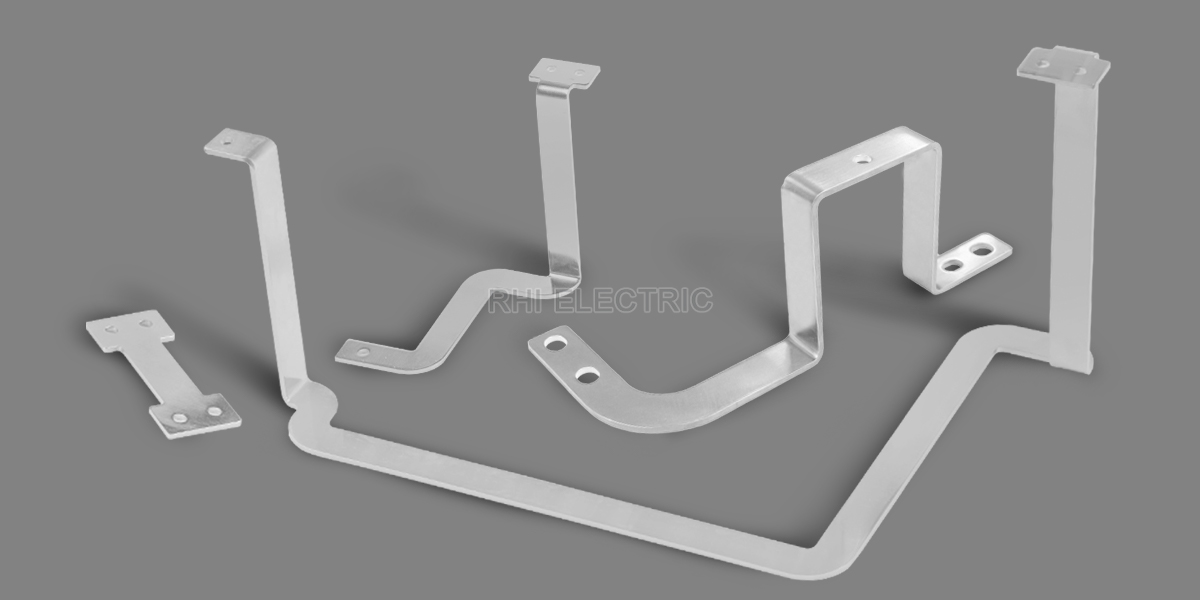

Rigid aluminium busbars are ideal for power connections in distribution panels. These power busbars offer precise bending and easy installation, making them suitable for space-saving integrated setups. With high electrical conductivity and resistance to electrical surges and mechanical stress, they ensure long-term system stability. Aluminium busbars can be customized and insulated with PVC for enhanced corrosion resistance and electrical safety. Their strong bending and tensile strength allow them to maintain shape under high voltage without deformation.

The aluminium busbar has a smooth, oxidation-resistant surface. The PVC insulation offers strong electrical strength and arc tracking resistance, ensuring reliable performance in high-voltage environments. It prevents arcing and short circuits, protecting the insulation and improving system safety. Rigid aluminium busbars are easy to process, install, and can be connected via welding or bolts, reducing installation time and labor costs.

Advantage

- Cost Efficiency: Rigid aluminum busbars are lightweight, offering significant cost savings while ensuring reliable electrical conductivity.

- Electrical Surge Resistance: Capable of withstanding high-voltage electrical surges and mechanical stress, ensuring stable system operation.

- Low Maintenance: Durable with a smooth surface, reducing maintenance frequency and costs.

- Insulation Safety: Provides excellent electrical strength and arc tracking resistance, effectively preventing arcing and short circuits, ensuring reliable insulation.

- Ease of Processing and Installation: Easy to process and install, with flexible options for welding or bolt connections, reducing installation time and labor costs.

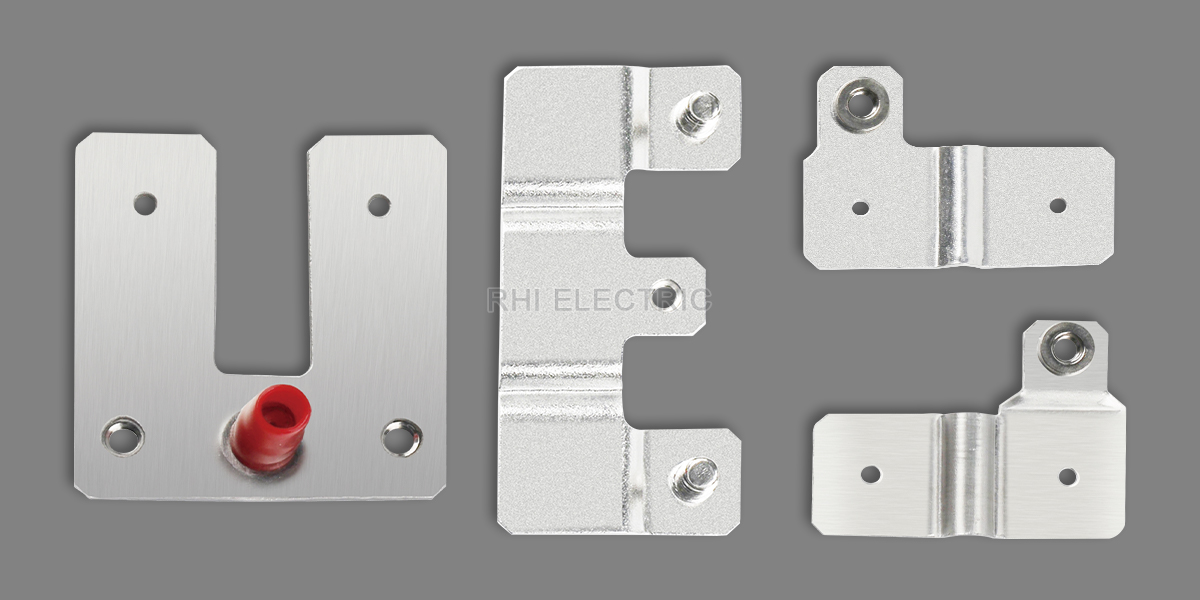

Product Details

|

Material Standard: |

Aluminium (1060) Or other specified materials. |

|

Insulation Treatment: |

PVC (dipping) Thickness: 0.8-2mm |

|

Operating Temperature: |

-40 to +125 º |

|

Quote Response Time: |

After receiving the drawings and verifying their feasibility, it will take 5-7 days to make a quotation. |

|

Quality Management Standard: |

Meet Auto Industry IATF16949 |

|

Eco-friendly Certificate: |

RoHS, REACH |

|

Delivery Time: |

The delivery time will take about 15-20 days after payment. |

Manufacturing Process Display

The aluminium substrate undergoes cutting, stamping, bending, perforating, and surface cleaning to remove oxide layers and oil. It is then preheated to the appropriate temperature. Next, the aluminium busbar is immersed in liquid PVC, where the PVC coating process forms a uniform insulating layer, ensuring excellent electrical performance and wear resistance. Finally, after cooling and curing, a quality inspection is conducted to ensure uniformity and strong adhesion of the PVC layer, resulting in a finished PVC-coated rigid aluminium busbar.