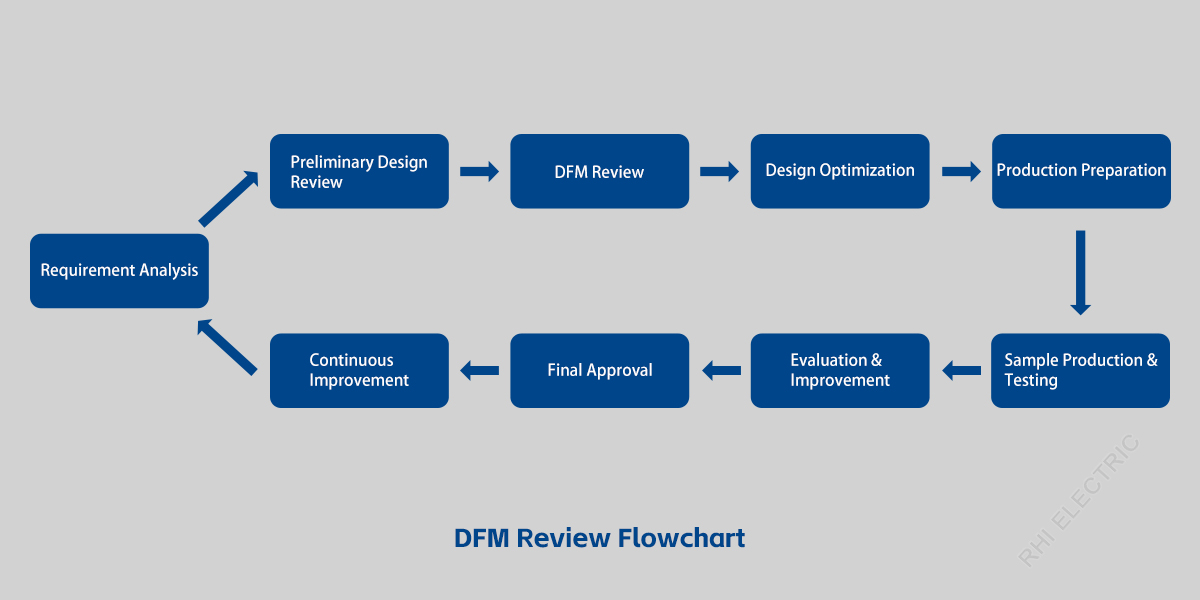

DFM Review

Design for Manufacturability (DFM) Review is a critical process in product development aimed at enhancing the manufacturability of products by considering manufacturing constraints and capabilities during the design phase. At RHI, the DFM review process ensures that busbar products are optimized for efficient production, cost-effectiveness, and quality.

R&D Design

R&D Design at RHI focuses on innovation and the development of cutting-edge busbar solutions tailored to meet the evolving needs of various industries, including electric vehicles, energy storage, and industrial power systems. The R&D design process emphasizes advanced engineering techniques, rigorous testing, and collaboration to ensure high-quality products that excel in performance and reliability.

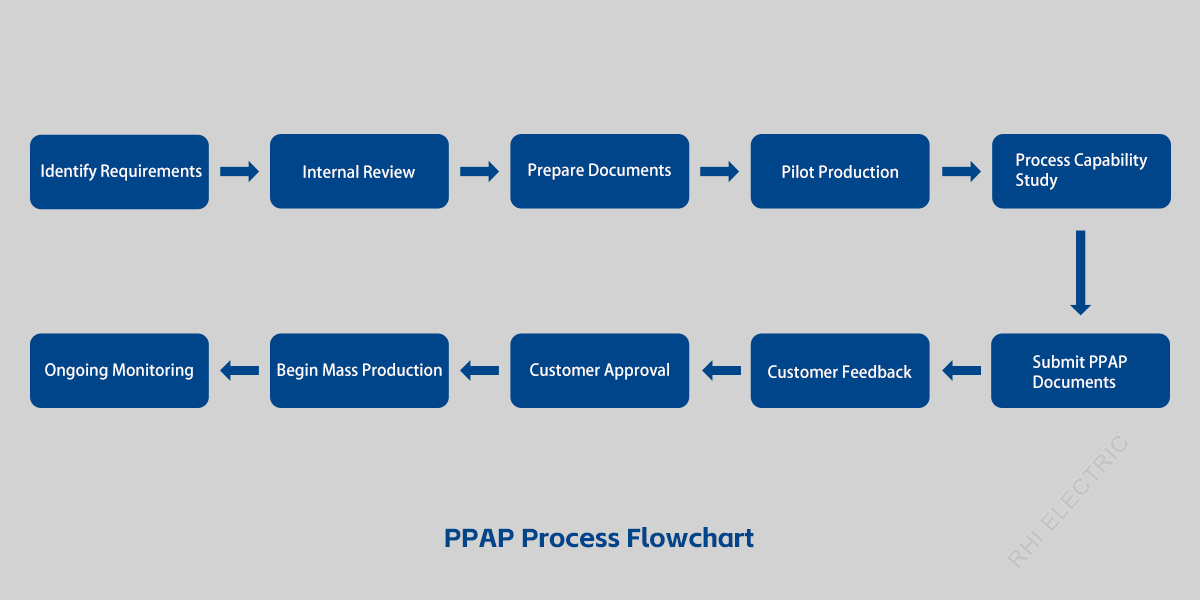

PPAP & APQP

PPAP (Production Part Approval Process) and APQP (Advanced Product Quality Planning) are essential quality management methodologies used in manufacturing, particularly in industries like automotive and electronics, to ensure that products meet design specifications and quality standards. At RHI, these processes play a crucial role in ensuring that busbar products are developed and manufactured to the highest quality standards.

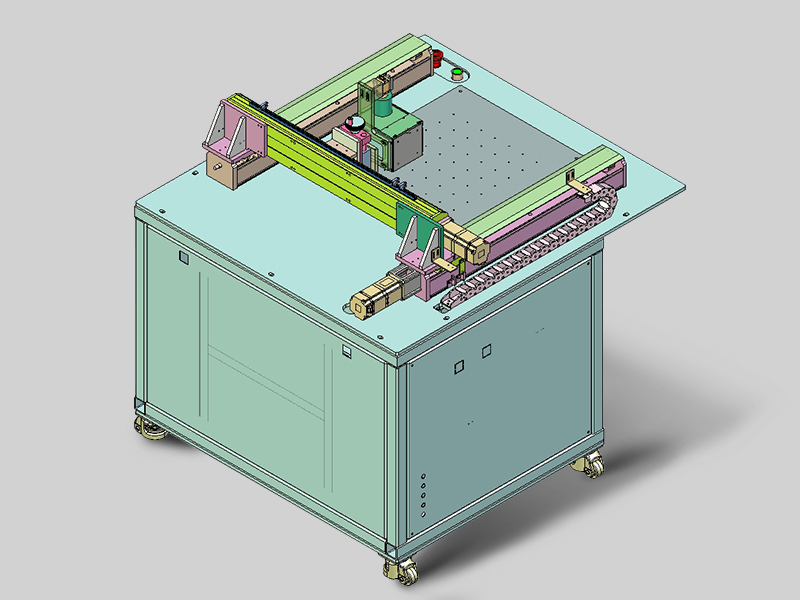

CCD Inspection

CCD Inspection (Charge-Coupled Device Inspection) is a highly advanced imaging technology used in manufacturing and quality control processes to ensure precision and accuracy in product inspection. At RHI, CCD inspection plays a crucial role in the quality assurance of busbar products, enabling rapid and reliable detection of defects and dimensional variations.