Bending Process of Electrical Busbars

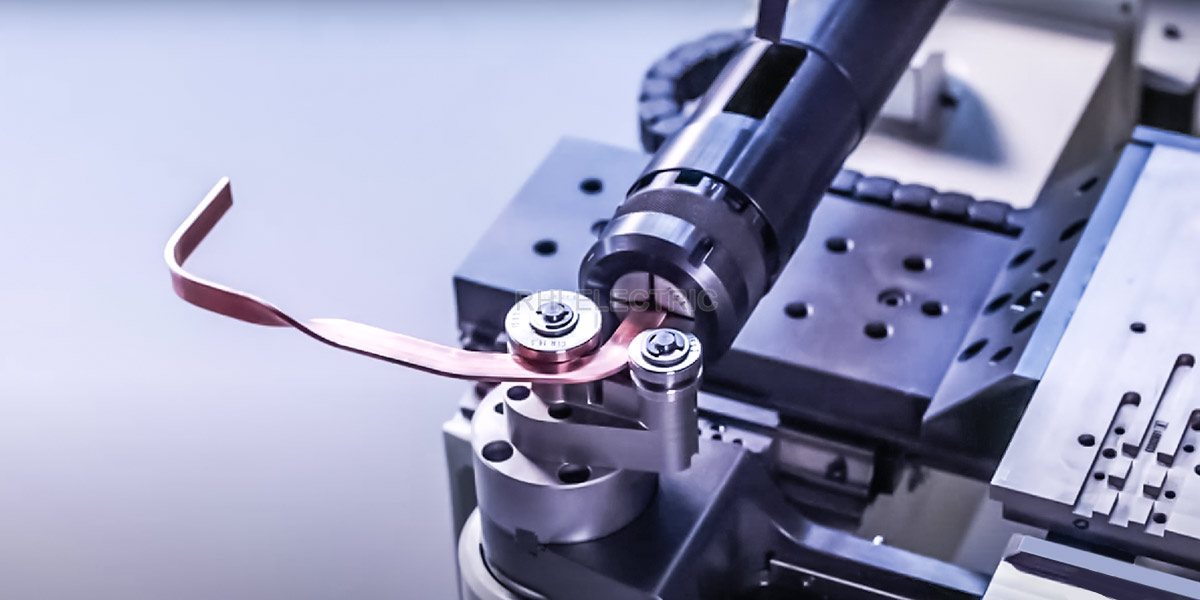

The spring machine is one of the essential devices in our bending process, primarily used for precision twisting of busbar materials. This technique is suitable for specific electrical applications and achieves a helical twist through meticulous control. This twisting process enables electrical busbars to maintain stable electrical performance and mechanical strength in high-vibration and high-impact environments.

Spring Machine: Precision-Controlled Twisting Process

The spring machine is one of the essential devices in our bending process, primarily used for precision twisting of busbar materials. This technique is suitable for specific electrical applications and achieves a helical twist through meticulous control. This twisting process enables electrical busbars to maintain stable electrical performance and mechanical strength in high-vibration and high-impact environments.

The spring machine carefully controls the uniform stress distribution on the busbars, avoiding stress concentration issues common in traditional bending processes. This reduces material fatigue and fracture risks. The technology is particularly suited for electrical connections in high-voltage environments, significantly enhancing the reliability and lifespan of EV busbars.

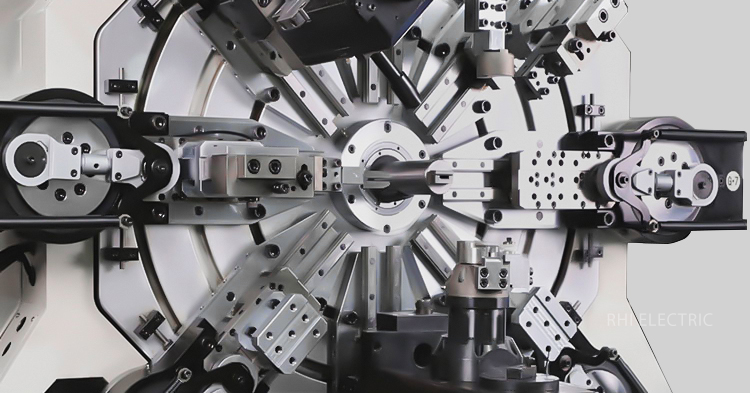

3D Automatic Bending Machine: Multi-Dimensional Precision Bending

We have also introduced advanced 3D automatic bending machines, further enhancing our custom busbar processing capabilities. Utilizing computer numerical control (CNC) technology, these machines perform precise bending in three-dimensional space, accommodating complex shapes as per design requirements. This technology ensures that each bending angle and radius is executed with high precision.

.png)

Compared to traditional manual bending methods, the 3D automatic bending machine greatly improves production efficiency, minimizes human error, and ensures high consistency and accuracy of the products. This is especially crucial in the design of electric vehicle battery packs, where busbars require precise bending shapes to fit within confined spaces and optimize current pathways. The 3D automatic bending machine allows operators to flexibly adjust the shape and structure of the busbars, ensuring superior electrical performance and mechanical strength in various complex environments.

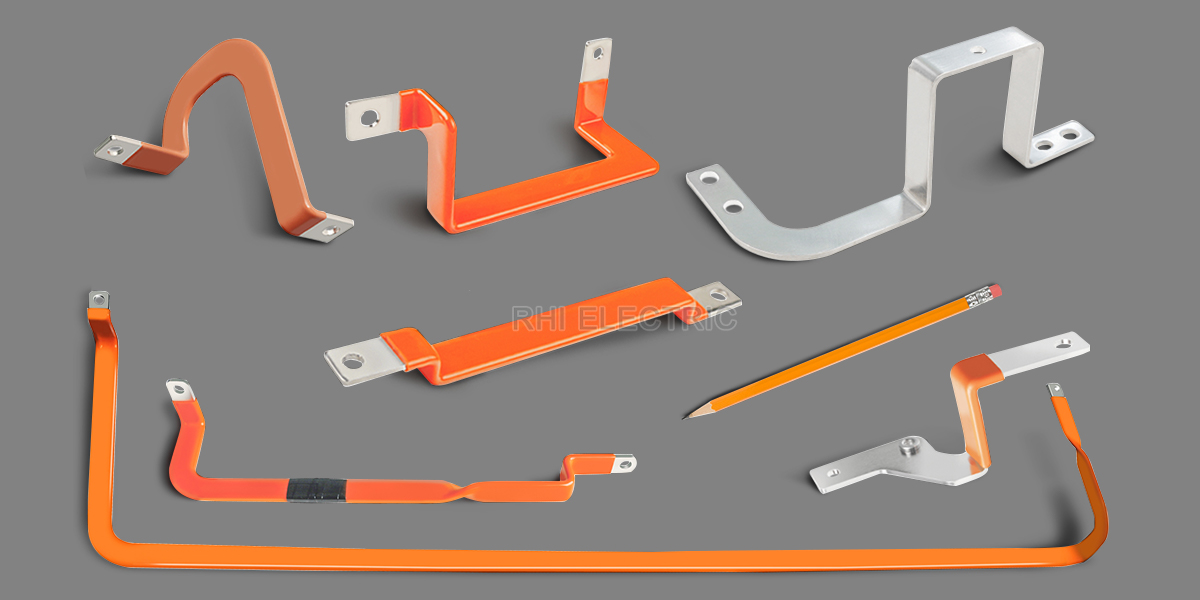

In the busbar manufacturing industry, the bending process affects not only the shape and size of the products but also their electrical performance and mechanical reliability. The combination of spring machines and 3D automatic bending machines enables RHI to meet diverse design requirements and application scenarios, providing customized busbar solutions for our clients.

By optimizing bending processes and upgrading equipment, RHI efficiently produces busbars that adhere to strict quality standards, ensuring precision and reliability. RHI is dedicated to technological innovation and process improvement to enhance product performance and customer satisfaction, supporting clients in achieving higher electrical efficiency and system stability in the new energy market and driving industry advancement.