DFM: Enhancing Quality, Reducing Costs in Busbar Manufacturing

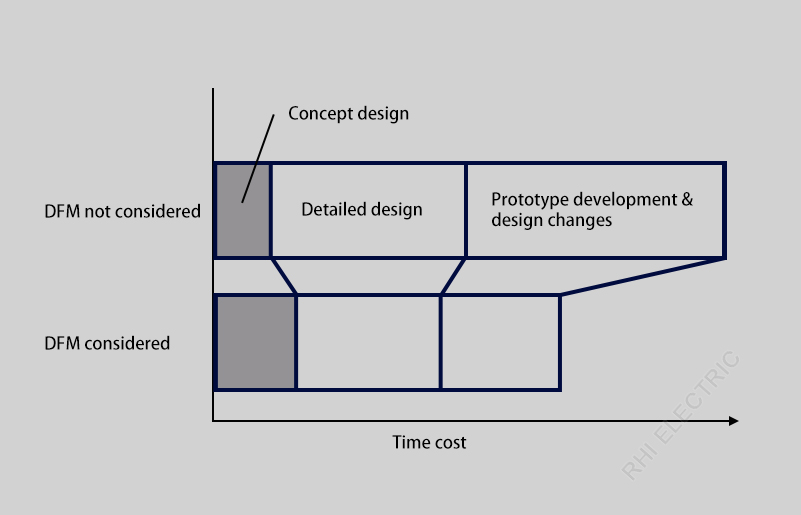

As a manufacturer of new energy busbars, RHI recognizes the vital role of Design for Manufacturability (DFM) reviews in improving product quality and reducing costs. DFM is more than a technical approach—it’s essential for mutual success with our customers.

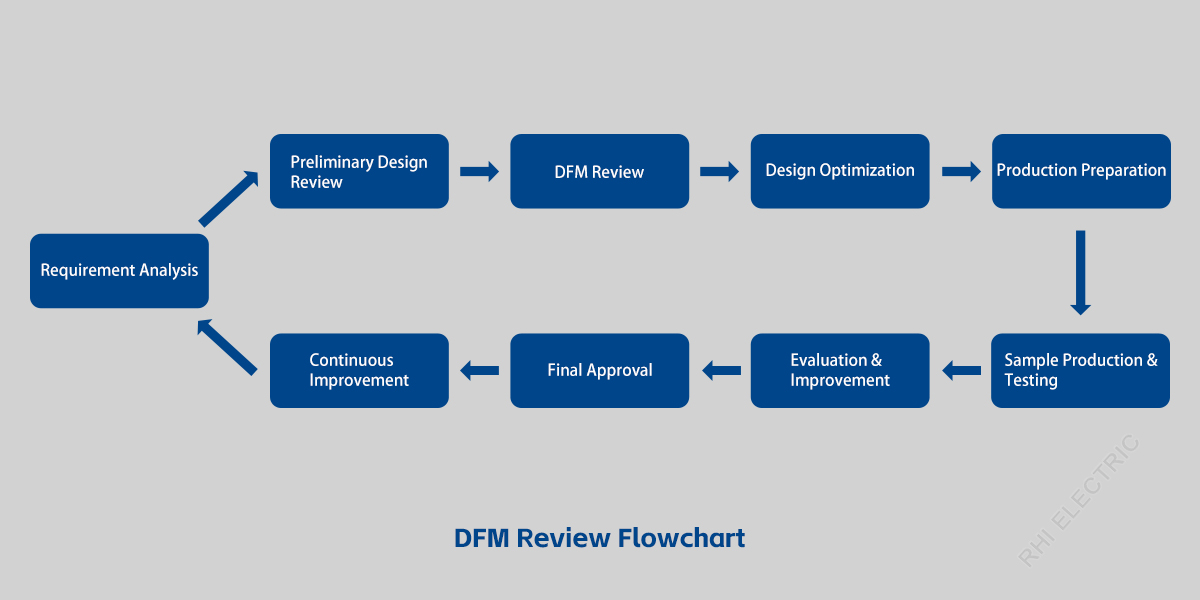

DFM Review Process

Our DFM review is a systematic and comprehensive process that starts at the initial design stage. Through multiple stages of review and analysis, RHI ensures the design is fully optimized for manufacturability before production begins. Our process includes:

- Preliminary Design Assessment: Analyzing the initial design to identify potential manufacturing challenges.

- Process Feasibility Analysis: Evaluating the practical feasibility of the design with our manufacturing capabilities.

- Pre-production Review: Conducting detailed design optimization before manufacturing to ensure a smooth, efficient production process.

This structured review process ensures that every design decision supports efficient manufacturing and minimizes risks and costs.

Design Optimization

Design optimization is a critical part of our DFM review. Our team thoroughly analyzes and refines designs to address potential issues, including:

- Material Selection: Optimizing copper and aluminum busbar materials to ensure excellent conductivity and durability while controlling costs.

- Processing Techniques: Evaluating and refining manufacturing processes to reduce production time and material waste.

- Ease of Assembly: Improving designs to simplify assembly, lower labor costs, and increase production speed.

These optimizations enhance production efficiency and significantly reduce manufacturing costs, providing more competitive products for our customers.

Manufacturing Capability Assessment

Our DFM review also includes a comprehensive evaluation of manufacturing capabilities. We analyze how well the design aligns with our existing equipment and processes to ensure seamless production. Our capabilities include:

- Advanced Manufacturing Processes: Techniques like extrusion and hot pressing that ensure product consistency and high quality.

- Automated Production: Utilizing automated equipment to enhance efficiency and precision, especially for large-scale orders, ensuring timely delivery.

This in-depth understanding of our manufacturing capabilities helps prevent unnecessary adjustments and delays during production.

Cost Control

RHI achieves effective cost control through our DFM review in several areas, including:

- Material Utilization Optimization: Reducing material waste through optimized design, lowering material costs.

- Simplifying Processing Techniques: Streamlining production processes to eliminate unnecessary steps and boost efficiency.

- Minimizing Waste: Precise design and efficient manufacturing processes reduce waste and defects.

These strategies allow us to offer competitive pricing while maintaining high product quality.

Quality Assurance

Quality control is integral to our DFM review. RHI adheres strictly to international standards, conducting thorough quality checks at every stage, including:

- Quality Management System: Implementing a quality management system that meets international standards to ensure every aspect meets quality requirements.

- Product Testing: Performing comprehensive electrical and mechanical tests on busbars before delivery to ensure reliability and stability under various conditions.

These measures guarantee that our products consistently deliver high reliability and performance.

Technical Support

RHI provides comprehensive technical support in addition to our products. Through DFM reviews, RHI offers:

- Design Recommendations: Leveraging our expertise to provide professional design advice that helps optimize product design.

- Process Improvements: Proposing process enhancements tailored to customer needs to improve production efficiency.

- Material Selection Guidance: Offering expert advice on material choices to achieve the best balance between performance and cost.

Our goal is to help customers avoid potential issues early in the design stage, ensuring a smooth transition to production.

Customer Involvement and Feedback

RHI encourages active customer involvement throughout the DFM review process. Close collaboration allows us to better understand specific needs and expectations, ensuring designs meet both manufacturing and customer requirements.

- Customer Participation: Inviting customers to participate in the DFM review to jointly assess design manufacturability.

- Feedback and Improvement: Making prompt design adjustments based on customer feedback to continuously improve our design process and product quality.

DFM reviews are crucial for enhancing our manufacturing capabilities and reducing costs, helping us build trust and achieve win-win outcomes with customers. By rigorously optimizing designs and assessing manufacturing capabilities, RHI ensures every busbar product is high-quality and competitive.