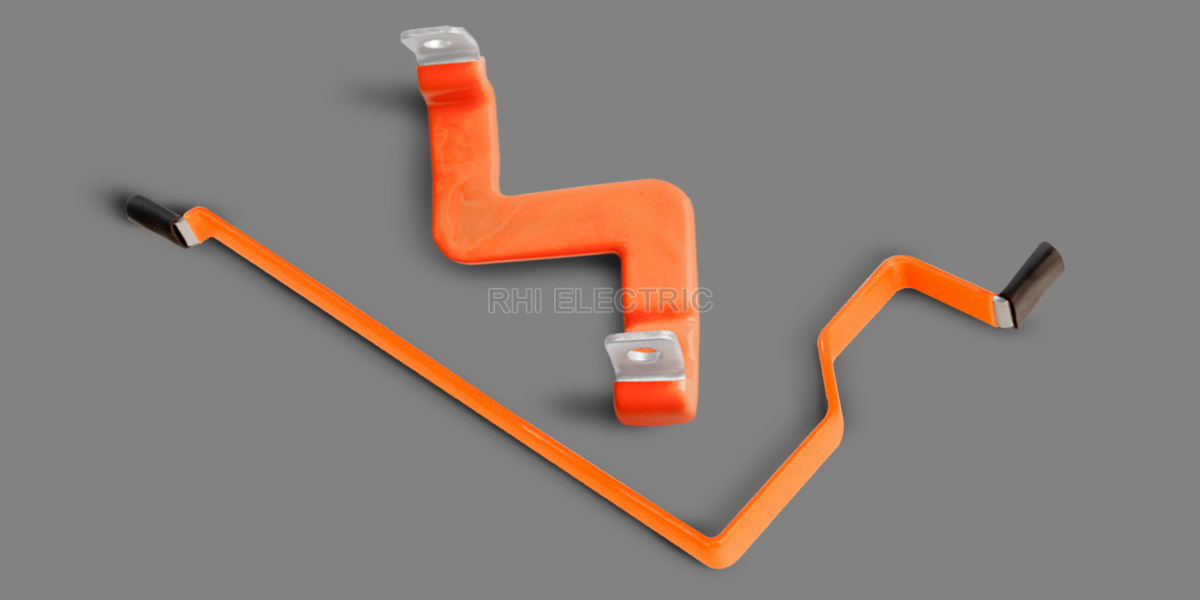

Flexible Aluminium Busbar Insulated for EV Applications

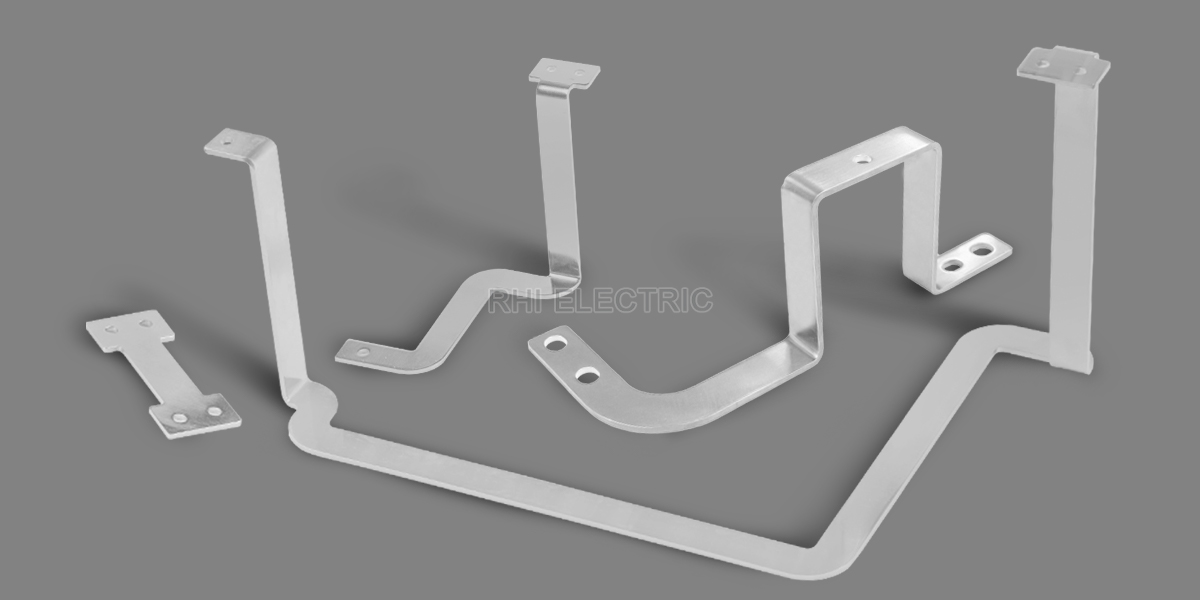

The flexible busbar, made of aluminium foil or strip and covered with an insulating layer, offers excellent conductivity, heat dissipation, and flexibility. It is lighter and more cost-effective than copper busbars while meeting current capacity requirements. Aluminium busbars are ideal for high-voltage series and parallel connections in electric vehicle battery packs, supporting the integrated assembly needs of electric vehicles.

Advantages

- Lighter weight and lower cost while meeting current capacity requirements

- Flexible conductor, supports quick perforation, flexible & practical installation, easy to operate

- Good conductivity & heat dissipation, decent shock & vibration resistance, good corrosion resistance

Product Details

|

Conductor Material: |

Al Strip or Foil Aluminium (1060) T2 Copper Or other materials per your request. |

|

Welding Process: |

Butt Welding/ Lap Welding |

|

Insulating Material: |

Heat Shrink Tube/ PVC (dipping) |

|

Working Temperature: |

-40 up to 105℃ |

|

Voltage: |

3500V AC |

|

Flame Retardant: |

UL94V-0 |

|

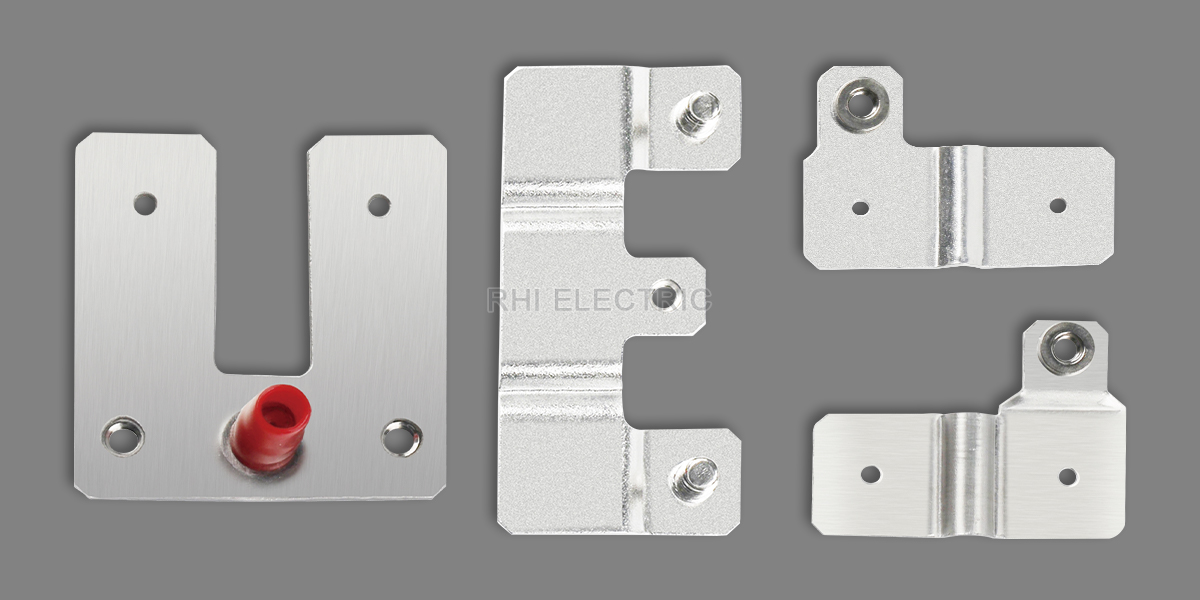

Punch Hole Design: |

Holes can be punched through the laminated strips/foils in either round or oblong shapes, as requested. |

|

Enterprise Certificate: |

IATF16949, ISO45001, ISO14001 |

|

Eco-friendly Certificate: |

RoHS, REACH |

|

Quote Response Time: |

After receiving the drawings and verifying their feasibility, it will take 5-7 days to make a quotation. |

|

Delivery Time: |

The delivery time will take about 15-20 days after payment. |

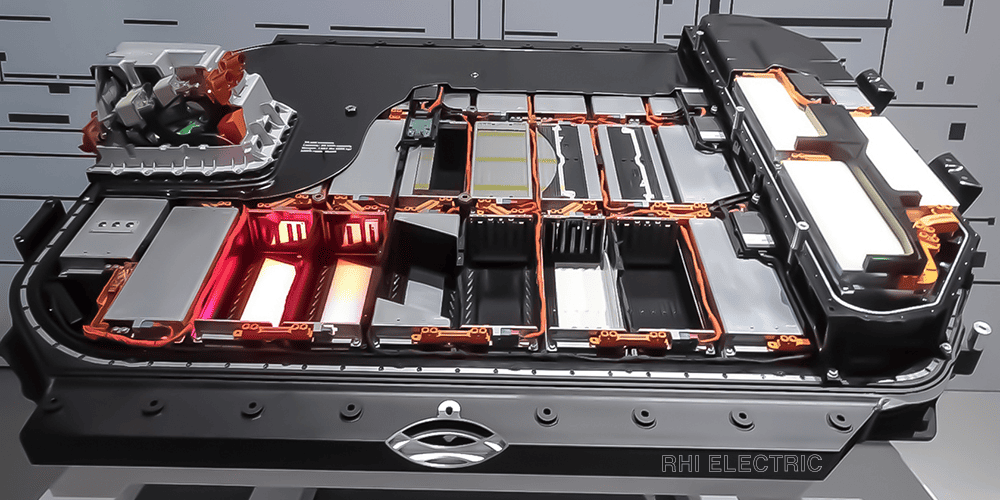

Application

In electric vehicle (EV) battery packs, PVC insulated flexible aluminium busbars provide reliable, efficient electrical connections. Made from aluminium strips with PVC insulation, they offer flexibility for easy integration into compact assemblies and are lighter than copper, reducing vehicle weight.

Despite their cost-effectiveness, these electrical busbars maintain excellent conductivity, heat dissipation, and current-carrying capacity, making them ideal for high-voltage connections. Their combination of safety, performance, and thermal efficiency supports the growing demands of modern EV designs, ensuring robust, lightweight power distribution.