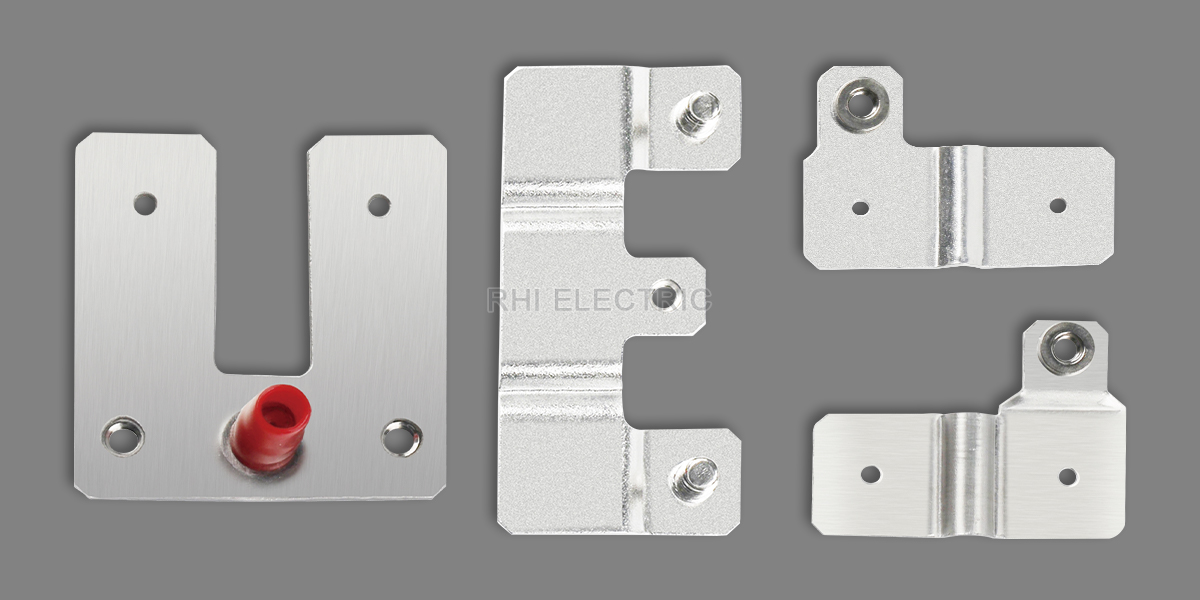

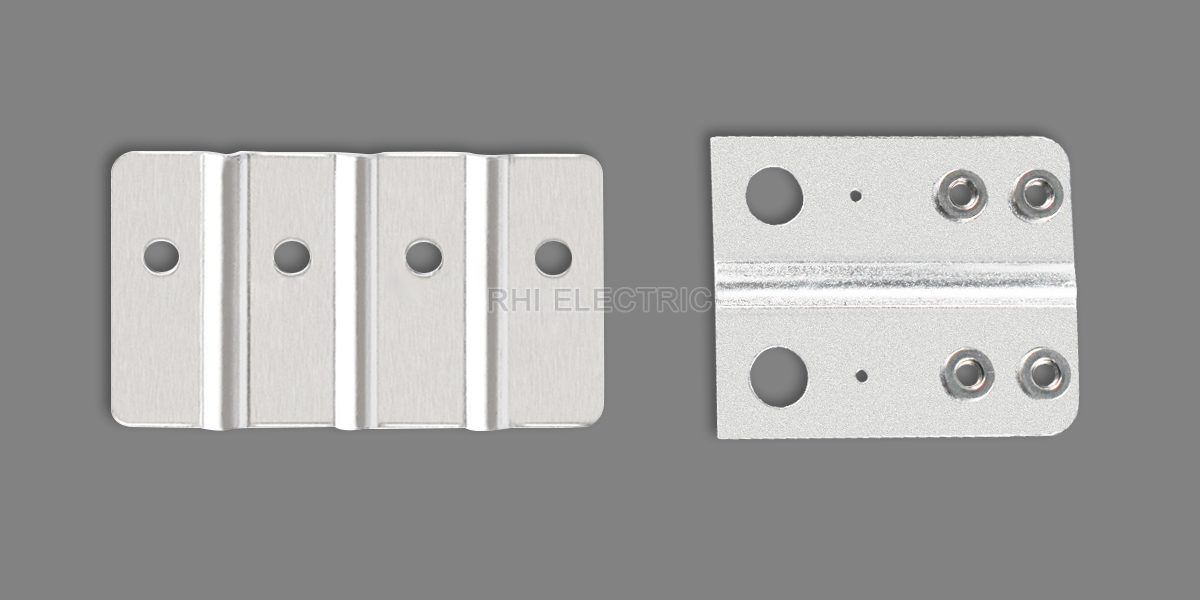

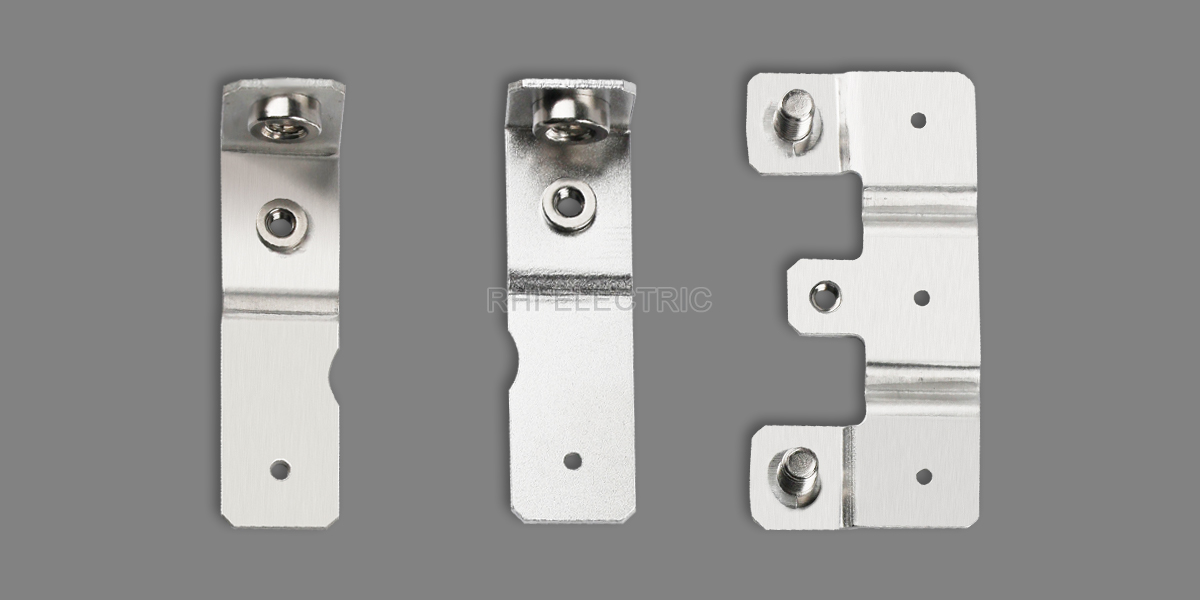

Aluminium Bus Bars for Cell Connection

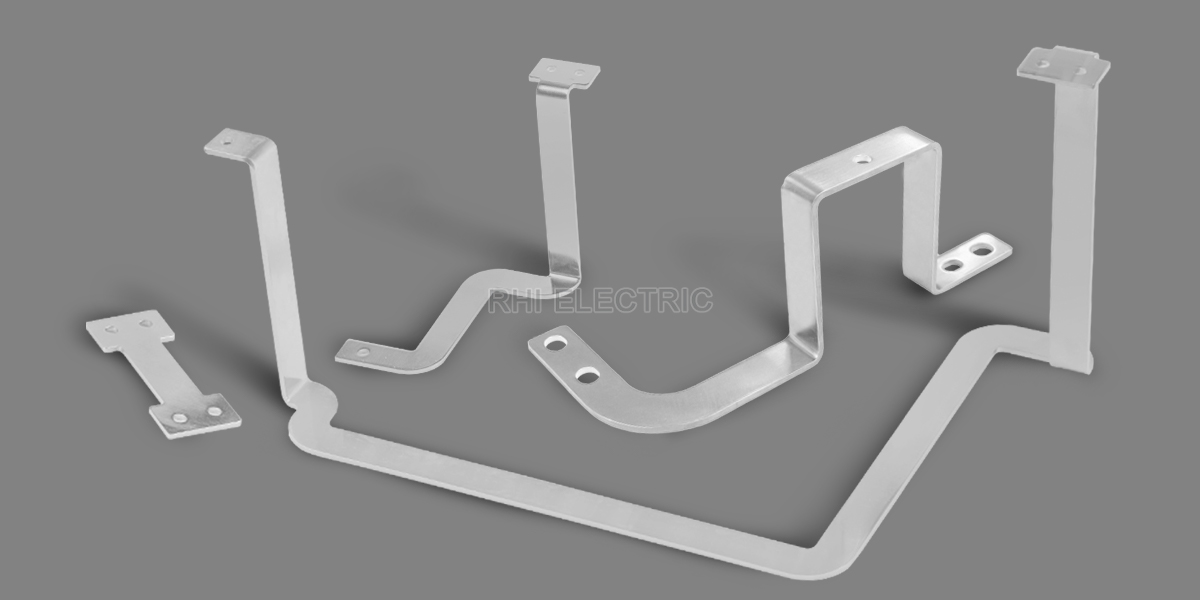

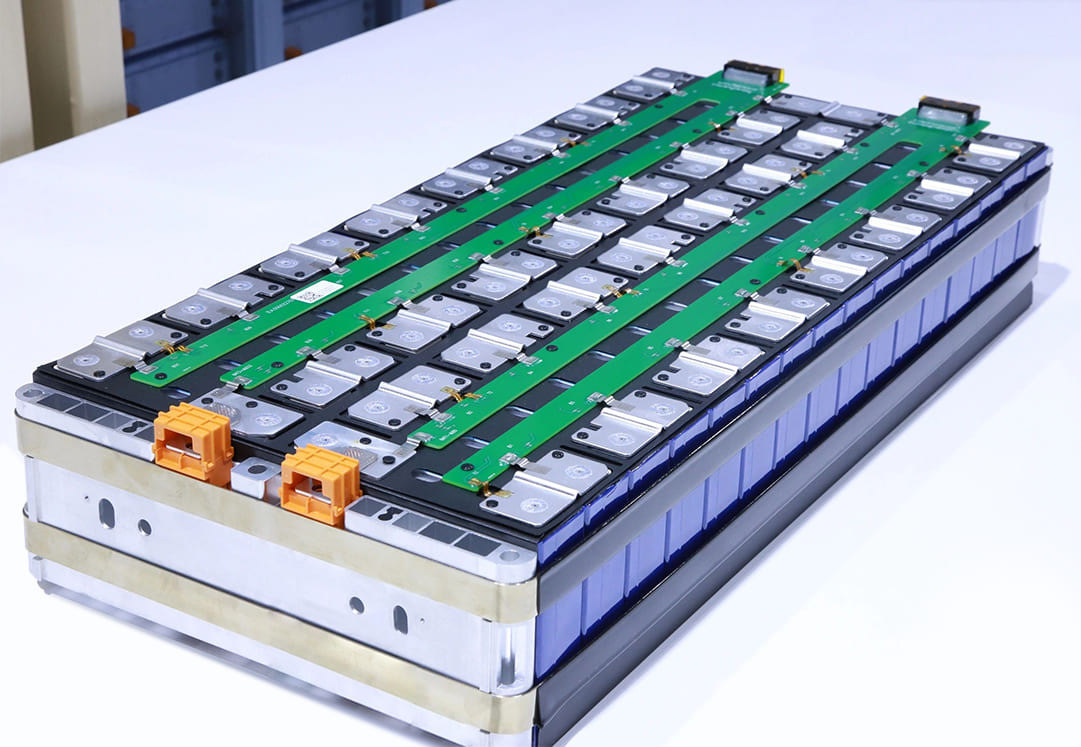

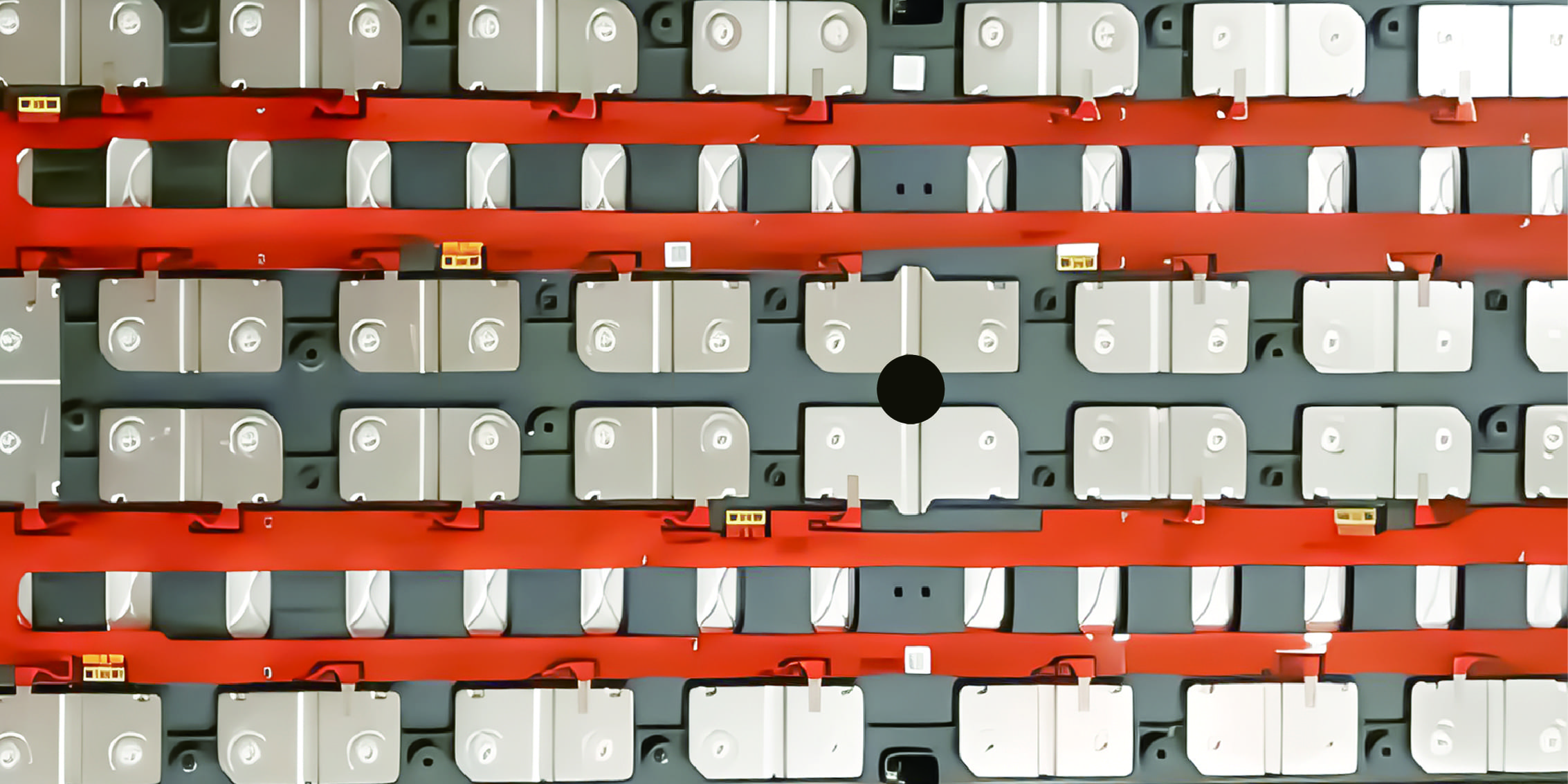

Compared to traditional wire harness, CCS busbars are lighter, more integrated, precise, and safer. These aluminium busbars enhance battery pack space utilization and assembly efficiency, meeting the demands for higher energy density, increased safety, and automated assembly in new energy batteries.

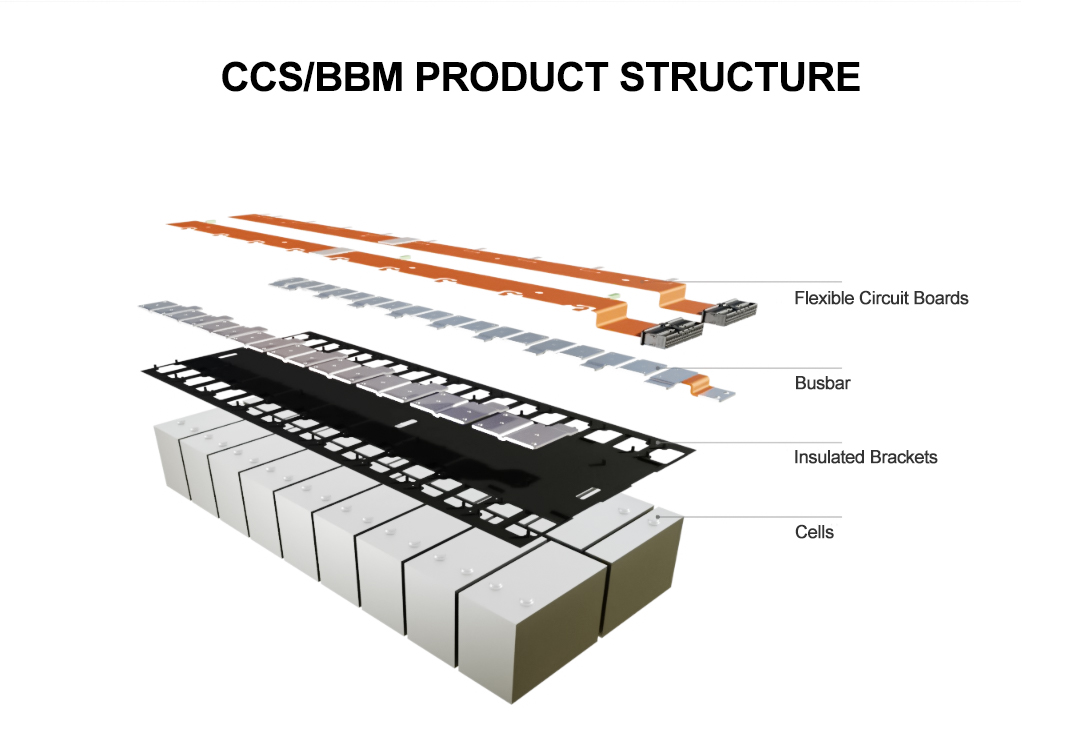

The CCS (Cells Contact System) integrated busbar is a key component of new energy battery packs. The electric busbar combines signal collection components (such as wire harnesses, FPCs, FFCs), plastic structures, and copper/aluminium busbars into a single unit through processes like thermo-compression bonding or riveting. This system enables high-voltage series and parallel connections of battery cells, as well as temperature and cell voltage sampling, forming part of the BMS system. It is applicable to new energy power batteries, energy storage batteries, etc.

As integration technology for new energy vehicle power batteries continues to advance and the application in energy storage accelerates, automation, cost reduction, and efficiency improvements are driving diverse development trends in CCS technology.

RHI has a professional R&D team providing cell connection solutions to drive the evolution of new energy power batteries. Integrating R&D, production, and sales, RHI supports custom designs and ensures comprehensive quality control of busbar products.

Click here to view the product video of this busbar.

Features

- Light weight

- Good conductivity

- Quick heat dissipation

- Stability and reliability

- Cost Effective

Product Details

|

Conductor Material: |

Aluminium (1060 ) Or as your request. |

|

Edge: |

Full Round Edges Rounded Corners Square Corners |

|

Width & Length: |

As your request. |

|

Certificate: |

IATF16949/ RoHS |

|

Quote Response Time: |

After receiving the drawings and verifying their feasibility, it will take 5-7 days to make a quotation. |

|

Delivery Time: |

The delivery time will take about 15-20 days after payment. |