Aluminium Busbar, Flexible Shunts for EV Applications

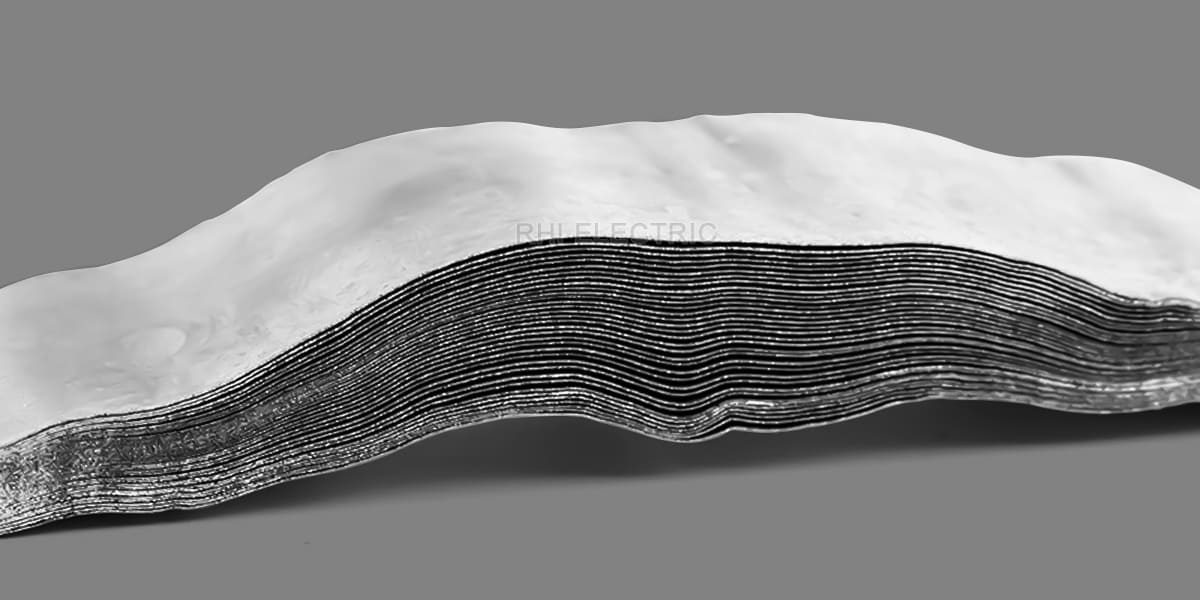

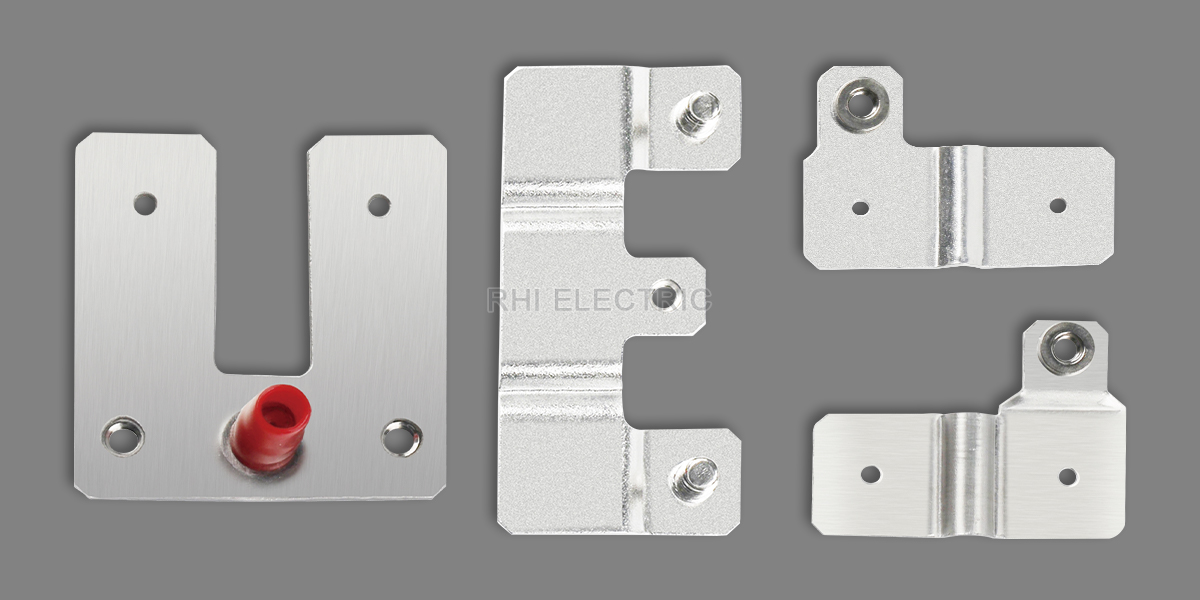

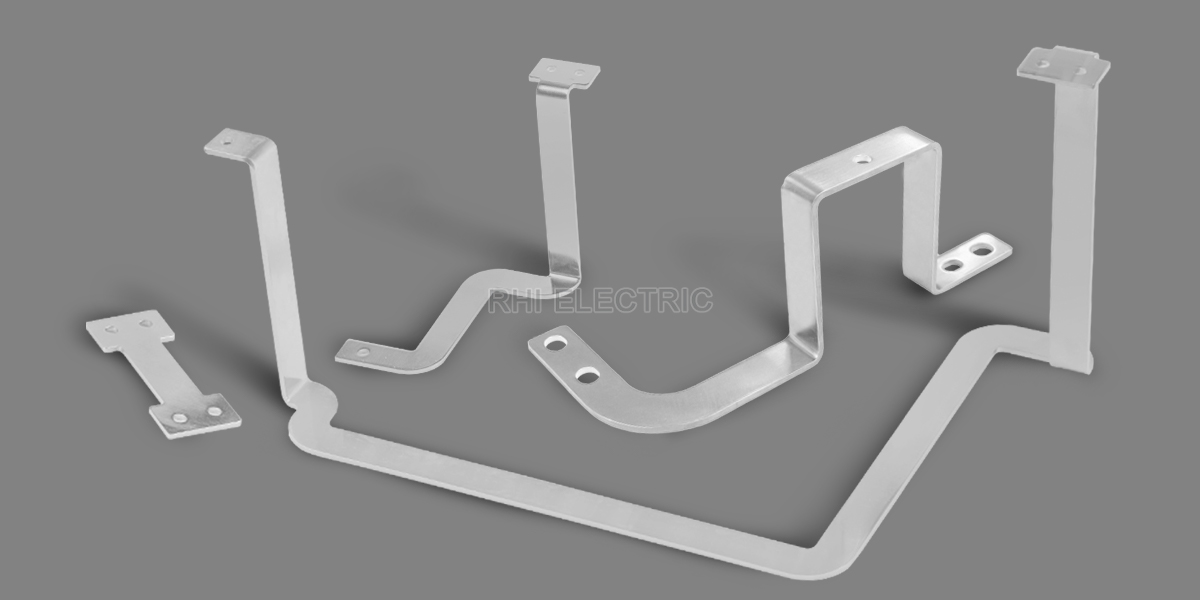

Aluminium flexible busbars are welded at both ends, with a flexible middle section that reduces mechanical stress on the busbar connector, enhancing installation flexibility. Aluminium busbars provide the necessary conductivity and thermal properties while offering lighter weight and significant cost advantages. These characteristics make them ideal for applications such as EV battery packs, where weight and cost are critical factors.

Features

- Made from aluminium foil or aluminium strip;

- Excellent conductivity and heat dissipation with lightweight design;

- Significant cost savings;

- Expansion joints absorb thermal contraction and minor movements, minimizing stress and busbar damage.

|

Material |

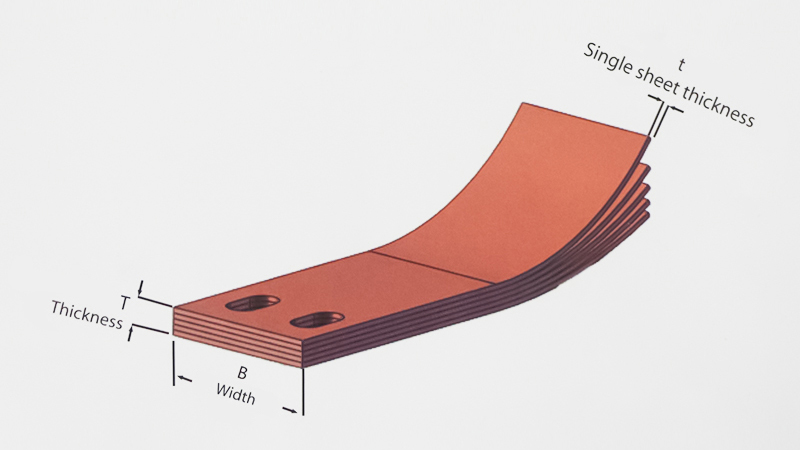

Single Sheet Thickness(t) |

Width(B) |

Thickness(T) |

||||||||

|

Al strip |

0.2 |

18 |

22 |

28 |

30 |

35 |

40 |

45 |

48 |

60 |

1~10 |

Product Details

|

Conductor Material: |

Al Strip or Foil Aluminium (1060 ) Or other materials upon request. |

|

Welding Process: |

Butt Welding/ Lap Welding |

|

Insulating Material: |

Heat Shrink Tube/ PVC (dipping) |

|

Operating Temperature: |

-40℃-105℃ |

|

Voltage: |

3500V AC |

|

Flame Retardant: |

UL94V-0 |

|

Punch Hole Design: |

Holes can be punched through the laminated strips/foils in either round or oblong shapes, as requested. |

|

Enterprise Certificate: |

IATF16949 |

|

Eco Certification: |

RoHS, REACH, ISO14001 |

|

Quote Response Time: |

After receiving the drawings and verifying their feasibility, it will take 5-7 days to make a quotation. |

|

Delivery Time: |

The delivery time will take about 15-20 days after payment. |

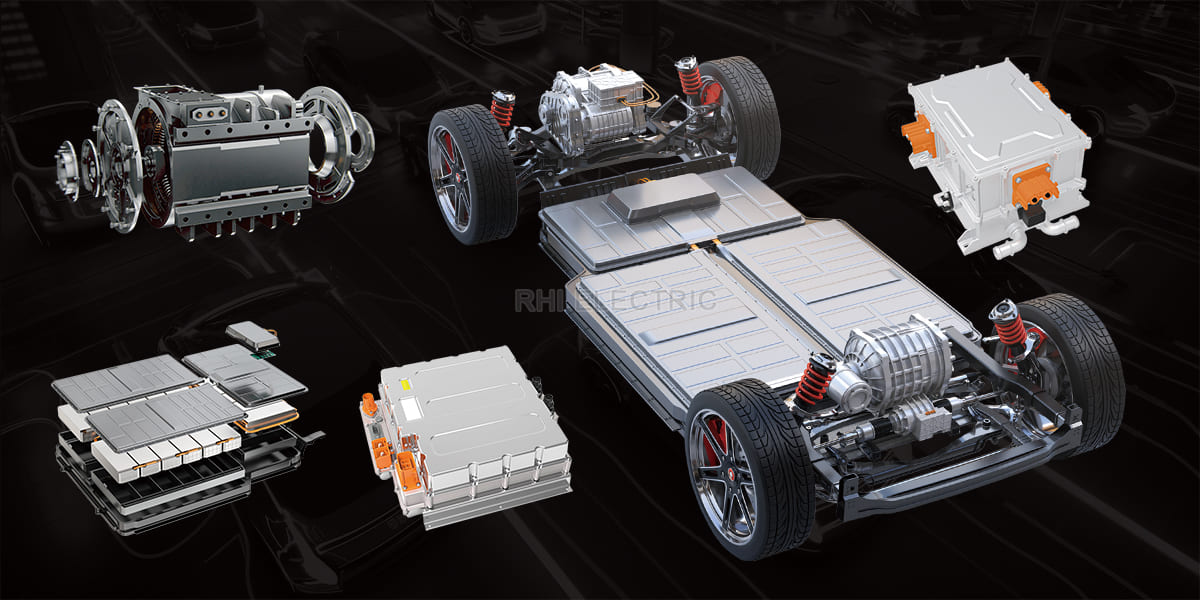

Applications

Flexible aluminium busbars are crucial in new energy electric vehicles (EVs). Their excellent conductivity, lightweight design, and bus bar connectors ensure efficient power transmission and reliable operation. As the EV industry advances, these flexible busbars will drive further technological progress and adoption.

- Battery Pack Connections: Flexible aluminium busbars connect battery cells within a pack, adapting to space constraints and thermal expansion, reducing resistance and energy loss for consistent power output.

- Battery Management System (BMS): In the BMS, these battery busbars connect battery cells to modules, ensuring accurate data transmission and reliable current distribution.

- High-Voltage System Connections: For high-voltage systems, flexible busbars handle large currents with low resistance, connecting the motor, inverter, and battery pack for efficient, safe operation.

- Motor Drive System: These aluminium busbars connect the inverter and motor, providing stable current transmission and efficient power output while absorbing vibrations and mechanical stress to extend component lifespan.

- Charging System: EV busbars connect the charging interface to the battery pack, accommodating various environments and standards to ensure efficient charging and effective heat dissipation.

- Onboard Power Distribution: In onboard power distribution, these power bus bars connect systems like air conditioning, electric power steering, and entertainment, ensuring stable power supply and equipment operation.