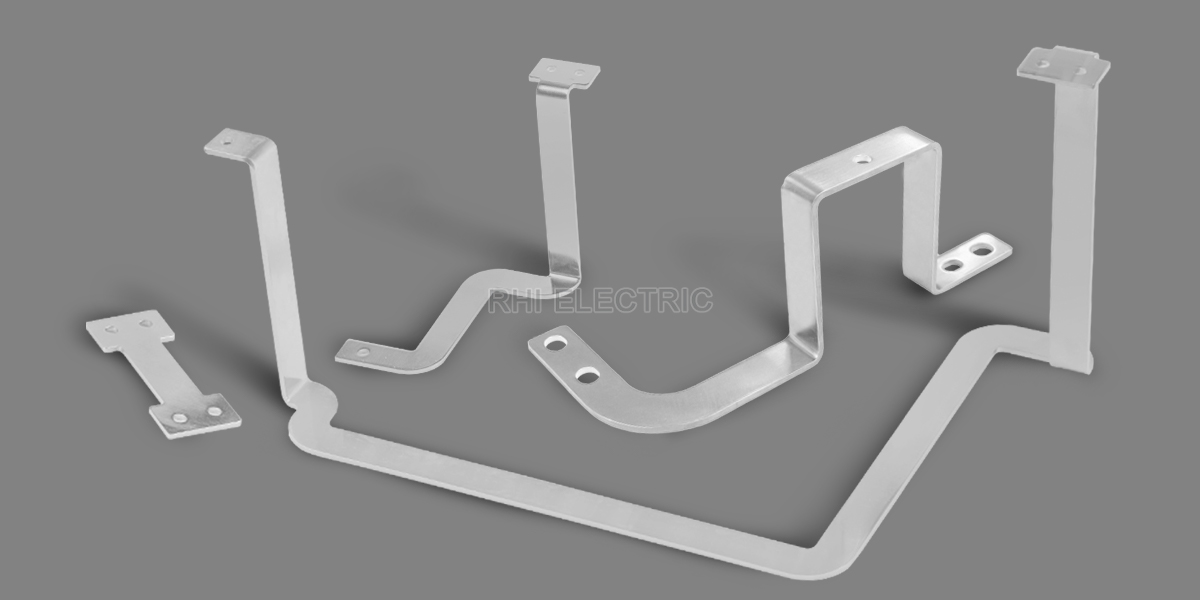

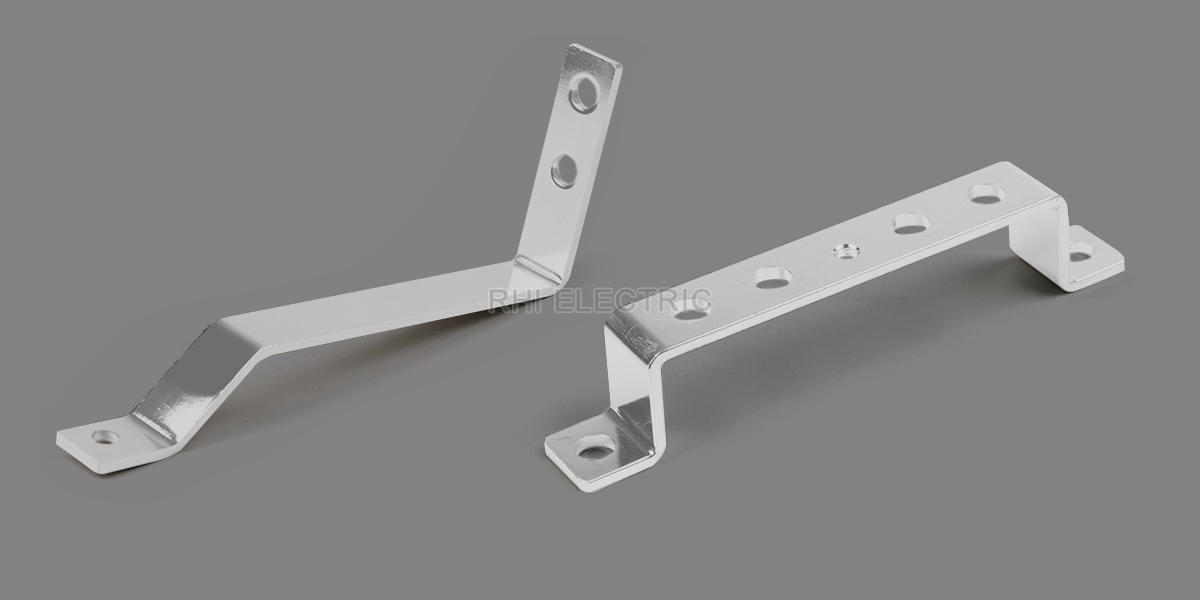

CNC Bending Rigid Aluminium Busbar

CNC bending aluminium busbars, made of pure aluminium, offer excellent conductivity and corrosion resistance. Advanced CNC bending ensures precise shapes and dimensions, enabling compact and efficient installation in power equipment and distribution systems. Key benefits include high current capacity, reduced power loss, increased reliability, and space-saving, making these rigid busbars essential in the modern electrical industry.

Advantages and Features

- High Conductivity: Made of high-conductivity pure aluminium, ensuring efficient current transmission.

- Excellent Heat Dissipation: Optimized material and design ensure good thermal conductivity, reducing heat accumulation.

- Cost-Effective: Pure aluminium material ensures high performance while being lightweight, offering significant cost benefits.

- High System Reliability: Reduces power loss and improves overall reliability and efficiency of the power system.

- High Space Utilization: 3D bending design allows for compact installation, maximizing space utilization.

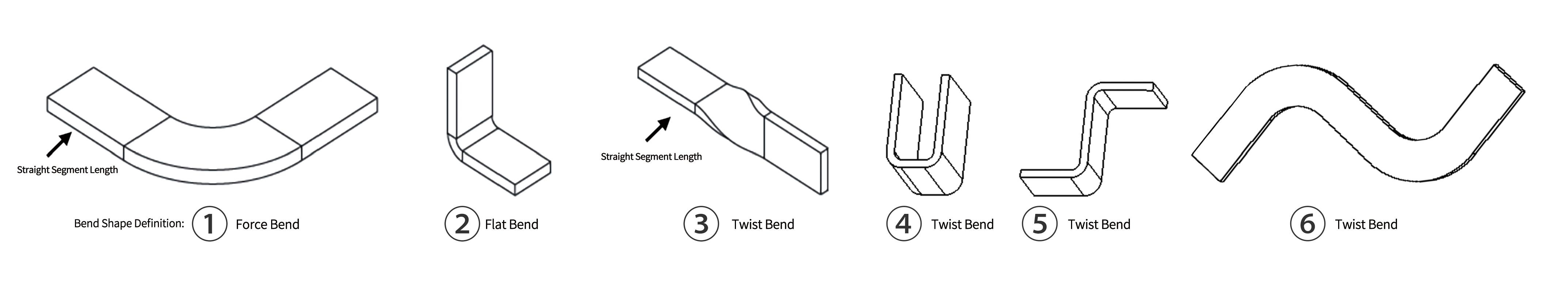

- Precise Bending Process: Advanced CNC technology ensures automated, high-precision bending, customizable to various angles to meet complex installation requirements.

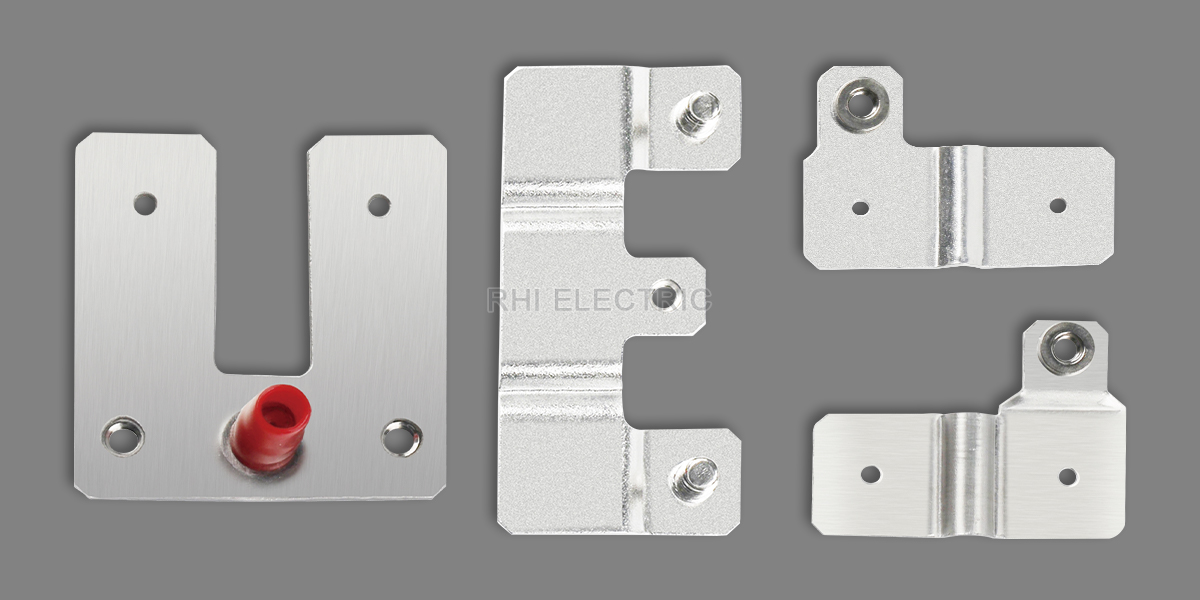

Click here to view RHI's busbar punching process.

| Thickness | Width | Number of Axes | Bend Factor |

| 1.0-5.0mm | 10-25mm | 6 | 0.8 |

Product Details

|

Material Standard: |

Aluminium (1060 ) T2 Copper Or other specified materials. |

|

Operating Temperature: |

-40℃-125℃ |

|

Quote Response Time: |

After receiving the drawings and verifying their feasibility, it will take 5-7 days to make a quotation. |

|

Quality Management Standard: |

Meet Auto Industry IATF16949 |

|

Eco-friendly Certificate: |

RoHS, REACH |

|

Delivery Time: |

The delivery time will take about 15-20 days after payment. |

Application

CNC bending aluminium busbars are ideal for the following applications due to their excellent conductivity, heat dissipation, and space utilization:

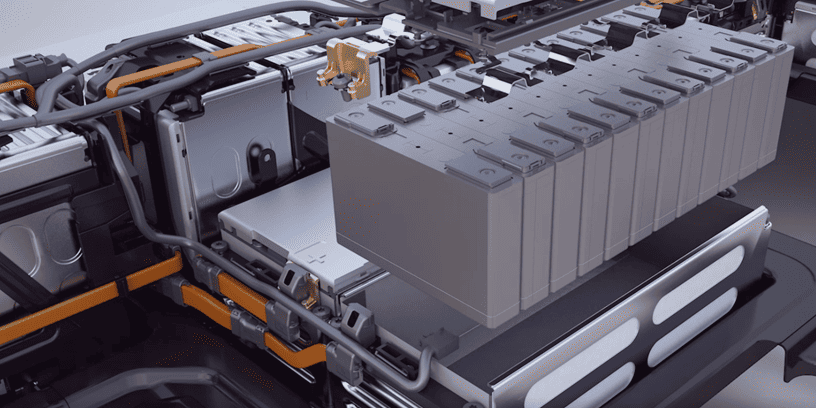

- Electric Vehicle Battery Packs: 3D-bent aluminium busbars offer precise current conduction and sturdy mechanical connections, enhancing the reliability and safety of battery packs in complex layouts.

- Energy Storage Batteries: These busbars manage high current transmission efficiently, with excellent conductivity and thermal resistance, ensuring effective energy storage and release.

- Distribution Cabinets: CNC bending aluminium busbars ensure reliable current distribution with high mechanical strength and superior heat dissipation, supporting stable operation under high voltage and current.

- Transformers: In transformers, these busbars provide stable current transmission and structural support while resisting high temperatures, ensuring safe and reliable operation under heavy loads.