What Is Bus Bar in Electrical Power System?

What is bus bar in an electrical power system, and why is it crucial for efficient power distribution in large-scale operations? In any electrical power system, efficient and safe energy distribution is paramount. Bus bars are integral to this process, serving as key components that facilitate the flow of electricity across the entire system. Whether it's in an industrial plant, residential power setup, or a power grid, bus bars help streamline operations, improve safety, and optimize space. If you're still wondering, What is bus bar in electrical power system?, this guide will delve into every aspect of this critical electrical component.

What Is Bus Bar in Electrical Power System?

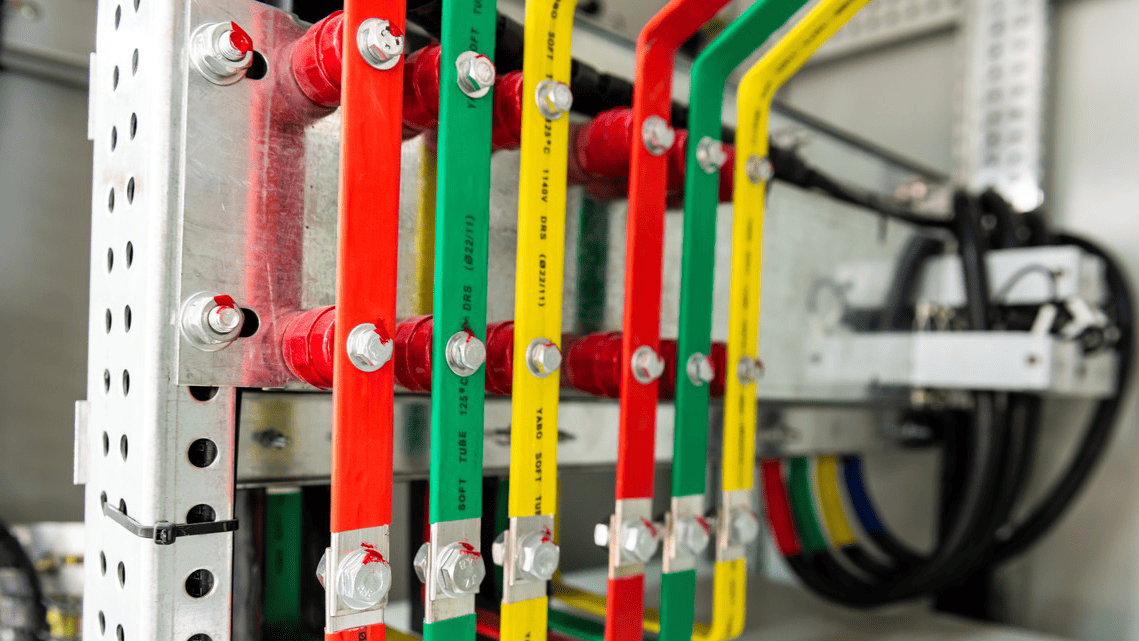

What is bus bar in electrical power system? It’s a crucial conductor that helps distribute power to different parts of the electrical grid while minimizing the risk of faults. A bus bar is a conductive metal bar or strip used to collect and distribute electrical energy across different parts of an electrical system. In simpler terms, it's a junction where multiple electrical circuits are connected, allowing power to flow between various components such as switches, transformers, fuses, and generators. The design of the bus bar is essential for minimizing resistance and maximizing power transfer, making it a core part of efficient electrical systems.

In most electrical power systems, bus bars are constructed from high-conductivity metals like copper or aluminum. Copper is the most commonly used material due to its superior electrical conductivity, while aluminum is often chosen for its lighter weight and lower cost. In certain high-strength applications, steel may also be used.

The bus bar plays an essential role by reducing the complexity of wiring and simplifying the interconnection between multiple components. It helps to consolidate connections into one central unit, making electrical systems easier to manage, and minimizing the risk of faults that might arise in a complex wiring network.

Role and Importance of Busbars in Power Systems

1. Power Distribution

When considering the design of a power grid, it's essential to ask, what is bus bar in electrical power system and how does it improve the overall efficiency of electricity distribution? One of the primary roles of a bus bar is to distribute power across the system. In large electrical setups, such as substations, factories, or grid distribution networks, bus bars form the central distribution point where electrical energy is divided and sent to various circuits or components. By connecting different sections of a system, bus bars ensure that power flows efficiently to all areas that require it.

In a typical power station, electrical energy generated by a generator is sent to a bus bar. From there, the power is distributed to various outgoing lines, which may then lead to homes, businesses, or industrial sites.

This type of distribution is crucial because it ensures that multiple electrical components can operate in harmony, without overloading any single point in the system. By consolidating circuits, bus bars prevent the need for multiple complex wiring connections, thus simplifying maintenance and improving reliability.

2. Simplification of Connections

In complex electrical systems, creating individual wire connections for each component can be an intricate and space-consuming task. Bus bars offer a simpler solution. Instead of running several wires between components, the bus bar acts as a central hub, where all circuits are connected.

This organization simplifies system design by reducing the overall number of connections and wire lengths required. It also reduces the chances of mistakes or shorts that may occur when dealing with a complex web of individual wires.

By allowing connections to be made to a single point, bus bars reduce the overall wiring complexity and enable easier troubleshooting and maintenance.

3. Current Flow Control

Managing the flow of electrical current is a vital aspect of any electrical system, particularly in high-power applications. Bus bars are designed to handle substantial current flows, often much higher than regular cables, without experiencing significant resistance or overheating.

They are generally made with larger cross-sections to allow for the efficient passage of large currents. This is particularly important in power stations, where bus bars are used to handle currents in the range of thousands of amperes. The ability of bus bars to safely carry high current levels without overheating or degrading is one of the reasons they are used in industrial and utility-scale electrical systems.

4. Improved Safety

Safety is one of the most important considerations when designing electrical systems, and bus bars contribute significantly to this. Their design minimizes the need for individual wires that could potentially be exposed to hazards, such as electrical shorts or fires.

Moreover, bus bars can be protected with fuses, circuit breakers, or isolation switches, ensuring that, in the event of a fault or overload, the affected section can be isolated without affecting the rest of the system. This protection helps to prevent catastrophic failures, such as electrical fires or equipment damage, improving the overall safety of the electrical infrastructure.

5. Reduced Voltage Drop

In traditional wiring systems, when electricity travels over long distances through cables, a voltage drop can occur due to the resistance of the conductors. This can lead to power losses, and in some cases, operational inefficiencies.

Bus bars offer a low-resistance pathway for the current to travel, reducing the chance of voltage drops, especially in large systems where power needs to be distributed over long distances. This ensures that electricity arrives at its destination with minimal loss of energy, helping the system perform more efficiently.

Construction of a Bus Bar

A bus bar’s construction is integral to its functionality. Below are the details of its components and construction process:

Materials Used

The material choice for a bus bar is critical because it directly affects its conductivity, durability, and capacity to handle high currents. The most commonly used materials include:

- Copper: Copper is preferred for its excellent electrical conductivity. It is capable of handling high currents with minimal resistance, making it ideal for large electrical systems where efficiency is a priority. Copper bus bars are also highly resistant to corrosion.

- Aluminum: While not as conductive as copper, aluminum is lightweight and less expensive. It’s often used in situations where cost savings are a priority, such as in residential systems or in scenarios where weight is a critical factor (e.g., for electric vehicles).

- Steel: In certain specialized systems where strength is a priority, steel bus bars are used. Steel is not as conductive as copper but provides more mechanical strength and can be used in certain high-mechanical-stress applications.

Shape and Design

Bus bars come in several shapes, each designed for specific applications:

- Flat Bus Bars: These are the most commonly used types. They are typically rectangular or square in shape and are used for most industrial and residential electrical systems. Their large surface area helps in distributing heat efficiently.

- Tubular Bus Bars: These are hollow cylindrical bars used in applications where additional current-carrying capacity is needed. Tubular bus bars are often found in high-power systems like substations or electric vehicles.

- Flexible Bus Bars: Made from braided copper or aluminum wires, these bus bars offer flexibility and are often used in systems that require movement or vibration resistance. They are commonly found in power electronics or high-frequency applications.

Insulation and Mounting

To ensure that bus bars remain safe during operation, insulation materials are used to prevent accidental short circuits or contact. These insulations could be:

- Rubber or plastic coatings for basic protection.

- Fiberglass for more robust insulation in environments where extreme conditions like heat or humidity might exist.

Bus bars are generally mounted inside electrical panels or switchboards. They are supported by insulated supports or bus bar channels to ensure alignment and safety during operation.

Types of Bus Bars

Bus bars can be classified into various systems, each offering unique benefits based on system size, flexibility, and redundancy:

1. Single Bus Bar System

In the single bus bar system, a single bus bar is used to connect multiple circuits. While it’s simple and cost-effective, it lacks redundancy. If there’s a fault in the bus bar, it can cause a total system shutdown. This setup is commonly used in smaller, less critical systems where downtime is acceptable.

2. Double Bus Bar System

The double bus bar system includes two bus bars, each capable of handling circuits independently. In case one bus bar needs maintenance or experiences a fault, the system can continue operating using the second bus bar. This system offers increased reliability but comes at a higher cost and requires more space.

3. Ring Bus Bar System

A ring bus bar system forms a continuous loop, ensuring that power can be rerouted in case of a failure in one section. This system offers maximum redundancy, making it ideal for critical applications like power stations and hospitals where downtime is not an option.

4. Sectionalized Bus Bar System

This system divides the bus bar into sections that can be isolated or bypassed. Each section can be individually controlled, which allows for flexible maintenance and fault isolation without affecting the rest of the system.

5. Bus Duct

A bus duct is an enclosed bus bar, often used for high current applications. This type of setup is designed for additional protection from external factors such as dust, moisture, and physical damage. It's commonly used in environments like factories and data centers where a more rugged solution is necessary.

Applications of Bus Bars in Electrical Power Systems

1. Power Distribution Stations

In power stations and substations, bus bars are the central components responsible for collecting and distributing electrical power from generators to transformers and various feeder lines. The reliability of the bus bar system directly affects the stability of the entire power grid.

2. Switchboards and Electrical Panels

Bus bars are typically housed within switchboards and electrical panels, providing easy access for maintenance and quick fault isolation. This is common in industrial and commercial buildings where many circuits need to be controlled and distributed.

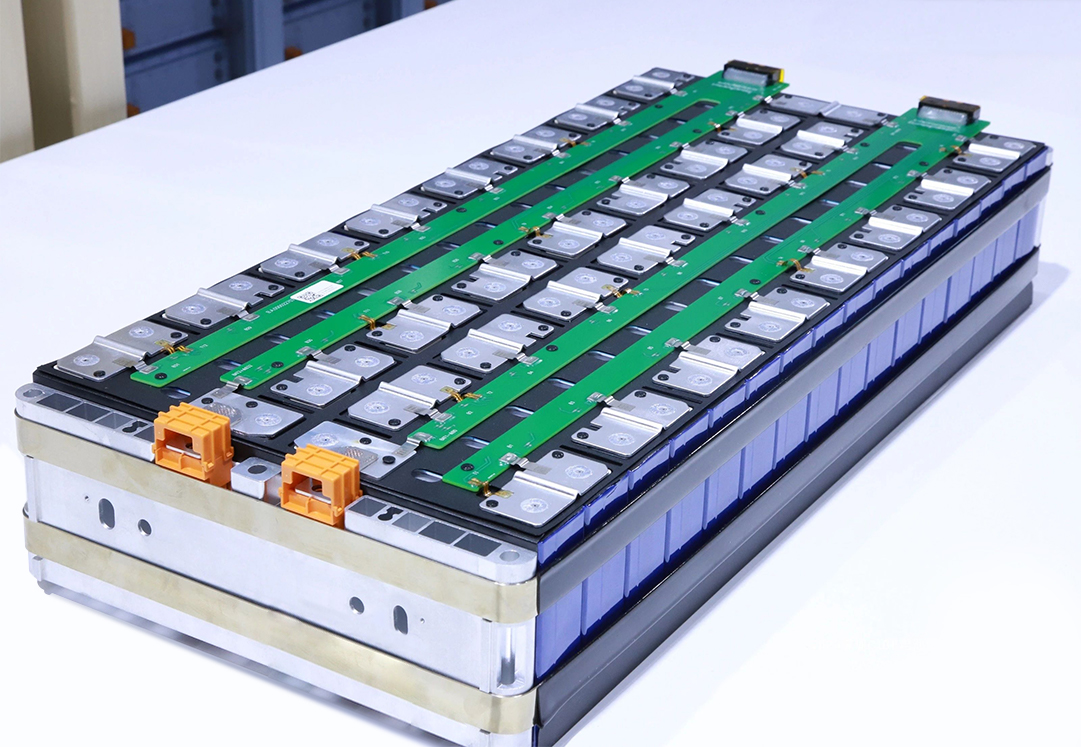

3. Electrical Vehicles and Battery Systems

In electric vehicles and battery management systems, bus bars play an essential role in distributing energy between the battery pack, the inverter, and other system components. Given the high current demands of these applications, copper or aluminum bus bars are often used to ensure efficient power transfer.

4. Data Centers and Communication Systems

Bus bars are used in data centers and communication systems to provide consistent and reliable power to the equipment. Given the importance of uptime in these environments, the use of bus bars helps reduce the risk of power outages and ensures that backup systems can be quickly activated in case of a failure.