What Is Electrical Bus Bar

Electrical systems are at the core of modern life, powering everything from household appliances to large-scale industrial machinery. One of the most essential yet often overlooked components in these systems is the electrical bus bar. Whether you're working in an industrial plant, designing a commercial building, or even installing a solar energy system, understanding what an electrical bus bar is can help you better understand how electricity is distributed efficiently and safely.

This comprehensive blog will explain what an electrical bus bar is, its functions, types, benefits, applications, and safety considerations. By the end, you will have a thorough understanding of this critical component and its importance in various electrical systems.

What Is Electrical Bus Bar?

An electrical bus bar is a highly efficient electrical component that acts as a central distribution point for electricity. Typically, it is a solid, conductive strip made of materials such as copper, aluminum, or brass, designed to conduct high currents. Its primary function is to gather electrical power from one or more sources and distribute it across multiple circuits or devices in a safe and organized manner.

The design of a bus bar can vary significantly based on its application, but it is generally a metal bar that allows multiple electrical connections to be made without requiring complex wiring. By providing a central hub for power distribution, bus bars simplify electrical systems and reduce the need for long cables, making them more compact and cost-effective.

In addition to its functional benefits, a bus bar is designed to carry high current loads with minimal resistance, preventing energy loss and reducing the chances of overheating. Bus bars are commonly found in electrical panels, switchboards, and control systems, where they play a vital role in distributing electricity to different parts of the system.

The Role of Electrical Bus Bars in Electrical Systems

Electrical bus bars are crucial for the efficient operation of any electrical system, particularly in environments where large amounts of power need to be distributed. Here are the key roles they play in electrical systems:

- Power Distribution: Bus bars are the main conduits for distributing electrical power from one central source to various branches or circuits within the system. For instance, in a power distribution panel, a bus bar might distribute electricity from a main power supply to individual circuit breakers or devices.

- Current Handling: A bus bar must be able to handle large currents without excessive heat generation or resistance. This makes bus bars ideal for systems that need to handle high power levels, such as industrial machinery, commercial buildings, and renewable energy systems.

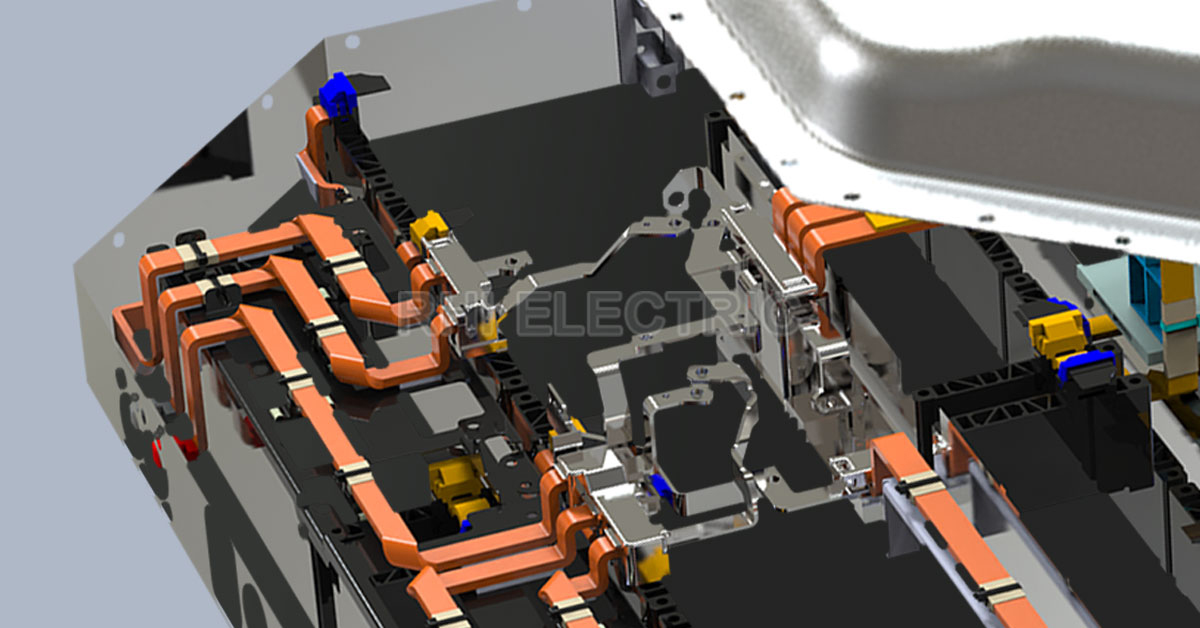

- Compact Design: Instead of using extensive wiring, bus bars offer a compact and organized method for distributing power. This can be especially valuable in spaces where wiring may be difficult to manage or where the system must fit into a confined space, such as in control cabinets, distribution boards, or even electric vehicles.

- Safety: One of the key benefits of bus bars is that they reduce the number of connections and wires in a system, thereby reducing the potential for electrical faults or shorts. In addition, bus bars can be housed in protective enclosures, ensuring that they remain safe from environmental damage and accidental contact.

- Improved Efficiency: By reducing the need for multiple individual cables, bus bars help improve the overall efficiency of the electrical system. They also minimize energy loss by providing a direct path for electricity to travel, as opposed to the resistance found in longer, tangled wires.

What Is Electrical Bus Bar: Types of Electrical Bus Bars

Electrical bus bars come in various types, each designed to suit specific applications and operational needs. Here’s a breakdown of the most common types of electrical bus bars:

Solid Bus Bars: Solid bus bars are the most straightforward and widely used type of bus bar. These are typically flat metal strips made of highly conductive materials such as copper or aluminum. Solid bus bars are commonly used in low- to medium-power applications and are ideal for use in industrial, commercial, and residential power distribution systems.

- Materials: Copper and aluminum are the most common materials for solid bus bars. Copper is highly conductive and resistant to corrosion, while aluminum is lighter and more cost-effective.

- Applications: These bus bars are often found in electrical panels, switchboards, and motor control centers.

Flexible Bus Bars: Flexible bus bars consist of braided or stranded conductors that allow the bus bar to bend or flex, making them ideal for installations where movement or vibration may occur. These bus bars are particularly useful in environments where space is tight or where electrical systems need to be adaptable to changing configurations.

- Materials: Flexible bus bars are typically made from copper or tinned copper, ensuring high conductivity while providing flexibility.

- Applications: They are often used in applications such as electrical vehicles, where flexibility and movement are required.

Insulated Bus Bars: Insulated bus bars are coated with insulating materials such as plastic or rubber to prevent accidental electrical contact. The insulation ensures that the bus bar can be safely handled without the risk of electrical shock or short-circuiting.

- Materials: The conductive material (usually copper or aluminum) is coated with an insulating layer, which can be made from various materials such as PVC, rubber, or other polymers.

- Applications: Insulated bus bars are used in high-voltage applications or environments where safety is paramount, such as in public buildings or hazardous industrial areas.

Tinned Copper Bus Bars: Tinned copper bus bars are coated with a thin layer of tin to prevent corrosion and improve their performance in humid or corrosive environments. The tin coating helps maintain the integrity of the bus bar and enhances its resistance to environmental factors.

- Applications: These are commonly used in outdoor installations or systems exposed to harsh environmental conditions, such as solar power systems or marine applications.

Bus Bar Trunking Systems (BBT): Bus bar trunking systems are advanced configurations of bus bars that incorporate multiple bus bars into a single, enclosed trunk. This type of system is ideal for large-scale electrical installations, such as data centers, industrial facilities, and commercial buildings.

- Applications: Bus bar trunking systems are used in high-power distribution systems where multiple circuits need to be connected in an organized and efficient manner.

What Is Electrical Bus Bar: Applications of Electrical Bus Bars

Electrical bus bars are used in a wide range of applications across different industries. Here are some of the most common uses of electrical bus bars:

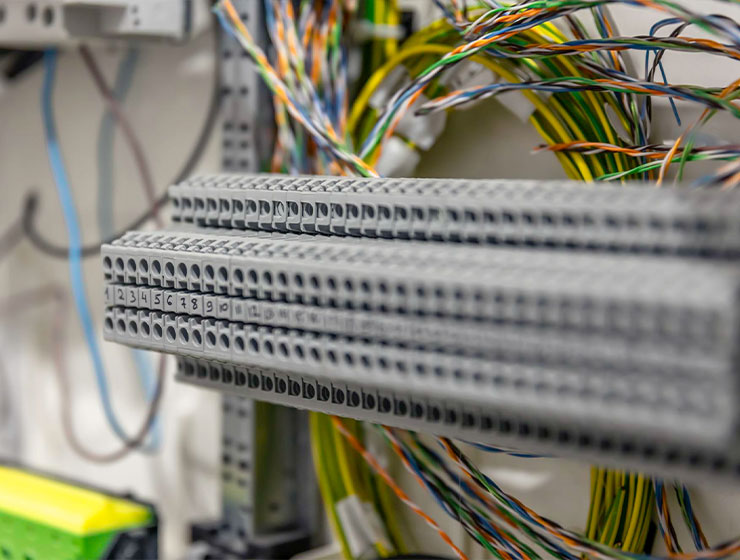

- Power Distribution Panels: Bus bars are a key component in power distribution panels, where they act as the central point for distributing electricity to different parts of a building or facility. These panels may house circuit breakers, fuses, or switches, all connected to the bus bar for power distribution.

- Switchboards and Electrical Cabinets: Bus bars are often found in switchboards, where they help manage and distribute electricity to various devices or circuits. These systems provide the infrastructure for managing power flow and protecting sensitive equipment from electrical faults.

- Electric Vehicles (EVs): In electric vehicles, bus bars are used to connect the battery pack to the vehicle’s electric motor and other components. These bus bars handle the high current demands of the electric drive system and provide efficient power distribution to the vehicle’s various electrical components.

- Renewable Energy Systems: In solar power systems, bus bars are used to connect the solar panels to the inverter, which converts the generated electricity into usable power. Bus bars are also used to distribute electricity to batteries for energy storage.

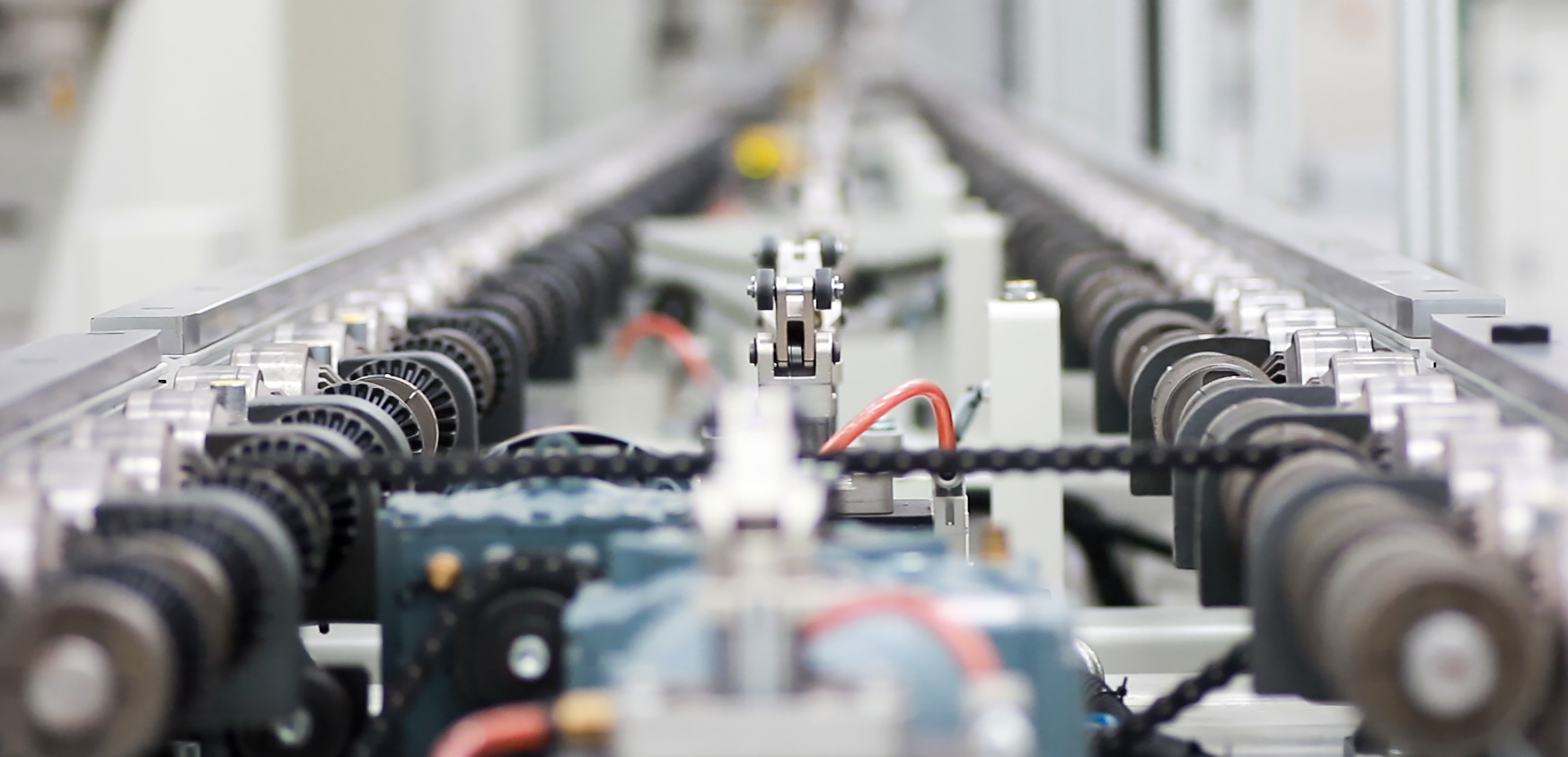

- Industrial Equipment: In large industrial machinery, bus bars are used to connect power sources to motors, generators, and other equipment. These bus bars help ensure a steady, reliable flow of electricity, reducing the risk of power loss or system failure.

What Is Electrical Bus Bar: Benefits of Using Electrical Bus Bars

Electrical bus bars offer several benefits that make them an ideal choice for power distribution in both large and small systems. Here are some of the primary advantages of using electrical bus bars:

- Efficiency: Bus bars allow for more efficient power distribution by minimizing energy loss. The direct connection between the power source and various devices reduces resistance and helps maintain voltage levels.

- Space-Saving: Bus bars help save space by reducing the need for long, complex wiring. This makes them especially useful in confined spaces such as electrical cabinets, control panels, and industrial equipment.

- Cost-Effective: Although the initial installation of bus bars may be more expensive than traditional wiring, their long-term benefits, such as reduced maintenance and increased reliability, make them a cost-effective solution.

- Simplified Maintenance: Bus bars are easier to maintain than traditional wiring systems. Their central location and organized design make it easy for technicians to perform routine inspections and troubleshoot issues quickly.

- Reliability: Bus bars are designed to handle high currents with minimal heat generation, which makes them highly reliable and durable over time. This reduces the likelihood of system failures due to overheating or poor connections.

Choosing the Right Electrical Bus Bar

Choosing the right bus bar for your electrical system is essential for ensuring optimal performance and safety. Consider the following factors when selecting a bus bar:

- Current Rating: The bus bar must be able to handle the required current without overheating. The bus bar’s current rating should be selected based on the total power needs of the system.

- Material: Copper is a highly conductive material that is often used for bus bars, while aluminum is a more cost-effective option. Choose the material based on your specific needs, including conductivity, cost, and environmental conditions.

- Size and Design: The size and design of the bus bar should match the available space and power requirements of the system. For larger systems, you may need a more complex bus bar trunking system to handle multiple circuits.

- Insulation: If safety is a primary concern, choose insulated bus bars to prevent electrical shock or short-circuiting. Insulated bus bars are particularly important in high-voltage applications.

Installation and Maintenance of Electrical Bus Bars

Proper installation and regular maintenance of bus bars are crucial for ensuring their long-term performance and safety. Here’s how to install and maintain bus bars:

- Installation: Bus bars should be installed in a secure, accessible location where they can be easily inspected and maintained. Ensure that the bus bar is mounted securely and that all connections are tight and properly insulated.

- Maintenance: Inspect bus bars regularly for signs of wear, corrosion, or damage. Look for any signs of overheating or loose connections, which could lead to electrical faults. Clean the bus bar periodically to remove dust and debris.

- Testing: Conduct regular electrical tests to ensure that the bus bar is operating correctly. Use multimeters or other testing devices to check for voltage, current, and resistance.

Safety Considerations

When working with electrical bus bars, safety is of the utmost importance. Follow these safety guidelines:

- Use Proper Insulation: Insulated bus bars help prevent accidental electrical contact and short circuits.

- Avoid Overloading: Ensure that the bus bar’s current rating is not exceeded, as this can lead to overheating and potential failure.

- Proper Grounding: Ensure that the bus bar system is properly grounded to avoid electrical shock hazards.

Conclusion

An electrical bus bar is an essential component in modern electrical systems. Whether you're working with industrial equipment, renewable energy systems, or residential electrical panels, understanding the role and benefits of bus bars can help ensure that your system is efficient, reliable, and safe. By choosing the right bus bar for your needs and maintaining it properly, you can ensure the long-term performance and safety of your electrical infrastructure.