Choosing the Right Electrical Bus Bar Connector for Your Application

Reliable and efficient power distribution is vital in modern electrical systems, with busbars serving as central hubs for electrical connections. A critical component in ensuring safe and effective power transmission is the busbar connector.

This blog highlights how to select the right busbar connector for your application, covering connector types, materials, installation tips, and key selection factors.

What is an Electrical Bus Bar?

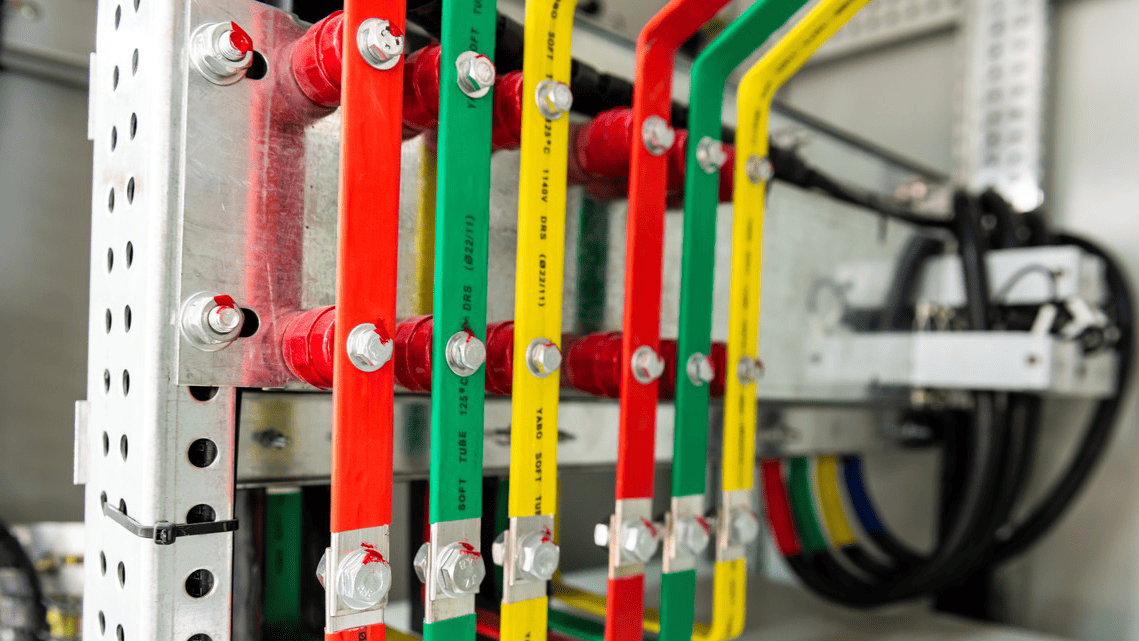

Before we dive into connectors, it’s important to understand what an electrical bus bar is and how it functions. A bus bar is a conductive metal bar or strip used in electrical systems to collect and distribute electrical power. It typically serves as a central point for electrical circuits, enabling the distribution of power to multiple outlets or devices. Bus bars are widely used in industries such as power generation, distribution, and various manufacturing sectors, as well as in consumer electrical applications like electrical panels and circuit boards.

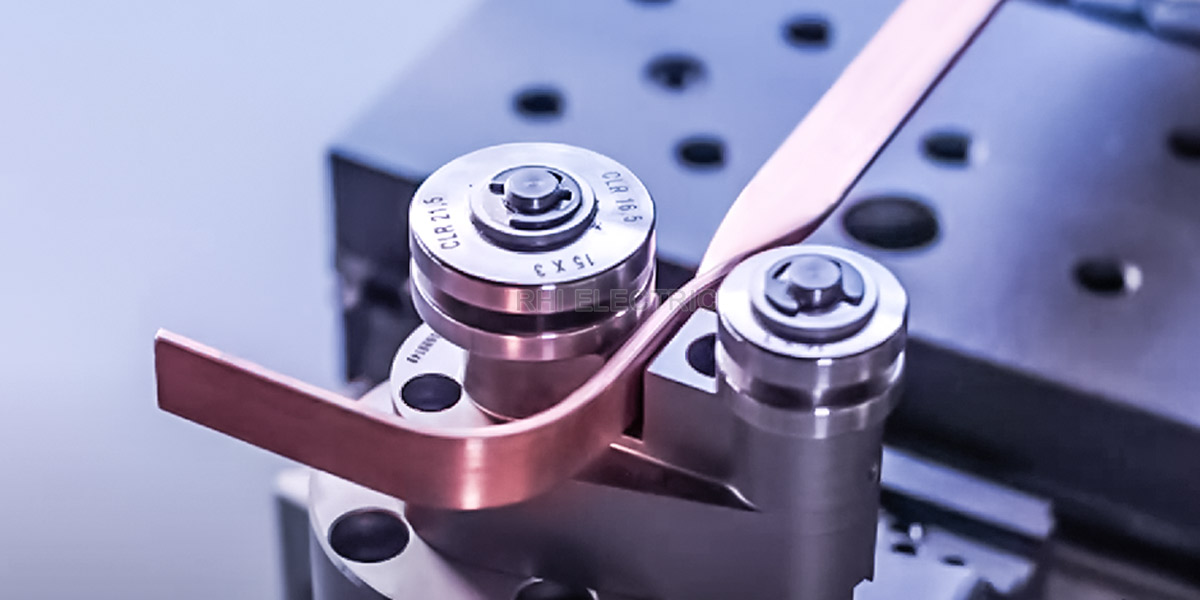

The electrical bus bar is designed to handle a high amount of electrical current and usually consists of copper or aluminum due to their excellent conductivity. The key purpose of a bus bar is to reduce the need for extensive wiring, thus simplifying electrical systems while providing a compact and efficient solution for power distribution.

Understanding Electrical Bus Bar Connectors

An electrical bus bar connector is a component used to connect the bus bar to other electrical components, such as circuit breakers, switches, or cables. These connectors ensure that electrical power is transferred safely and efficiently from the bus bar to various parts of the system.

The design of the electrical bus bar connector is critical because it must ensure a secure and reliable connection while handling the high current flow that is typical of bus bar systems. These connectors are available in various designs, materials, and sizes to suit different applications, making it crucial to choose the right type based on the electrical load, system requirements, and environmental conditions.

Key Factors for Choosing a Busbar Connector

When selecting an electrical bus bar connector, there are several factors that you must consider to ensure the connection is optimal for your specific needs. Let’s explore the key considerations:

1. Current Rating and Conductivity

The current rating of the electrical bus bar connector must be compatible with the current that will be flowing through the bus bar. Overloading a connector can lead to overheating, arcing, and ultimately failure. You should always verify the amperage rating of both the bus bar and the connector.

For most industrial applications, copper connectors are preferred due to their superior conductivity. However, aluminum connectors can also be used, especially for lighter-duty applications, as they are more cost-effective but offer lower conductivity than copper.

2. Material Compatibility

The material of the electrical bus bar connector should match the material of the bus bar to avoid galvanic corrosion, which can occur when dissimilar metals come into contact with each other. For instance, if you are using a copper bus bar, it’s best to use a copper bus bar connector. For aluminum bus bars, aluminum connectors should be chosen to ensure long-term reliability and prevent issues like poor conductivity and corrosion.

3. Voltage Rating

Each electrical bus bar connector comes with a voltage rating, which is the maximum voltage that the connector can safely handle. It’s essential to ensure that the connector’s voltage rating is appropriate for your system’s voltage to prevent electrical arcing or short circuits.

4. Size and Fit

The size of the electrical bus bar connector is critical for ensuring a secure and tight fit. The connector should match the dimensions of the bus bar, such as its thickness and width. Additionally, connectors should be sized appropriately for the cable or wire being connected to the bus bar.

5. Environmental Considerations

In many industrial applications, electrical systems are exposed to harsh environmental conditions, such as high humidity, temperature fluctuations, or corrosive chemicals. Choosing an electrical bus bar connector made from materials that are resistant to corrosion, high temperatures, or weathering is essential for ensuring durability and longevity.

6. Ease of Installation

Depending on the complexity of your electrical system, installation time and ease of use might be important factors to consider. Some electrical bus bar connectors are designed for quick and easy installation with minimal tools required. Others might require more advanced techniques or equipment, which may impact labor costs and downtime.

Types of Electrical Bus Bar Connectors

There are several types of electrical bus bar connectors, each designed to meet specific needs. Let’s take a closer look at the most common types:

1. Bolted Connectors

Bolted bus bar connectors are commonly used in high-power systems. These connectors feature a bolted mechanism that securely fastens the bus bar and wire or terminal to ensure a strong, stable connection. Bolted connectors are durable and provide a reliable electrical connection, but they can be more time-consuming to install.

2. Compression Connectors

Compression connectors are designed to form a tight connection by compressing the material (usually copper or aluminum) of the bus bar and the conductor. These connectors are highly effective at maintaining a solid connection and are often used in medium to high-voltage applications.

3. Clamp Connectors

Clamp-style bus bar connectors use a clamping mechanism to secure the bus bar to the wires or cables. These connectors are typically used for lower-current applications and are quick and easy to install, but they may not be as reliable under higher electrical loads compared to bolted or compression connectors.

4. Spring Connectors

Spring connectors use a spring-loaded mechanism to ensure a secure connection. These are often used in low-voltage and low-current applications where quick and easy installation is a priority. However, they may not be suitable for high-load or industrial-grade applications.

Choosing the Right Busbar Connector

Choosing the right electrical bus bar connector involves evaluating the specific requirements of your electrical system. Whether you are designing a new installation or replacing connectors in an existing system, it’s crucial to consider the following steps:

1. Define Your Requirements

Start by assessing the electrical load requirements, voltage levels, and environmental conditions of your application. This will help you narrow down the choice of connector types and materials. Consider factors like amperage, installation space, and operating temperature ranges.

2. Choose the Right Material

Select the appropriate material based on the bus bar you are using and the environmental conditions. For instance, copper connectors are ideal for high-conductivity needs, while aluminum connectors are a more cost-effective choice for lighter-duty applications.

3. Evaluate Connector Features

Look for additional features such as ease of installation, mechanical strength, and any other specific needs based on the layout of your electrical system. Some connectors come with additional protective coatings for corrosion resistance or enhanced durability in extreme conditions.

4. Verify Compatibility

Ensure that the electrical bus bar connector is compatible with the specific bus bar and electrical components in your system. Consider the size, voltage, current rating, and environmental conditions to select the optimal connector.

5. Consult with Experts

If you are uncertain about the selection process, it is always beneficial to consult with experts in the field of electrical systems or manufacturers of electrical bus bar connectors. They can provide valuable guidance on the best options for your specific application.