Top Advantages of Using Electrical Copper Bus Bars in Industrial Settings

In industrial settings, power distribution and electrical efficiency are vital to ensuring smooth operations and maintaining the integrity of equipment. The components used in these systems play a significant role in their overall performance, safety, and cost-effectiveness. One such critical component is the electrical copper bus bar. These conductive strips or bars are essential in transmitting and distributing electrical current throughout a system. In this blog, we will explore the top advantages of using electrical copper bus bars in industrial environments and why they are the preferred choice for businesses that prioritize performance, reliability, and longevity.

.png)

Superior Electrical Conductivity

The most significant advantage of using electrical copper bus bars is their exceptional electrical conductivity. Copper is one of the best conductors of electricity, second only to silver. This means that electrical copper bus bars can carry electrical current efficiently, with minimal resistance, ensuring that the energy transmitted from one part of a system to another remains intact.

Why It Matters:

In industrial environments, where power demands are high and electrical loads are substantial, using a material that offers minimal resistance to current flow is crucial. Electrical copper bus bars can handle large amounts of current without significant energy loss, making them ideal for high-demand settings like manufacturing plants, power distribution stations, and heavy machinery systems. By using copper, industries can reduce the need for oversized cables and minimize energy wastage, leading to more efficient systems and lower operational costs.

Additionally, copper’s high conductivity ensures that the electrical system runs smoothly, without frequent fluctuations or interruptions, which is vital for the consistent operation of sensitive machinery and equipment.

Durability and Longevity

Copper’s resistance to corrosion and wear makes electrical copper bus bars incredibly durable, which is one of the key reasons they are widely used in industrial settings. Unlike materials like aluminum or steel, copper is less susceptible to corrosion over time. Even in harsh environments, such as areas with high humidity or exposure to chemicals, copper retains its structural integrity and continues to perform at a high level.

Why It Matters:

In industrial settings, equipment and components are often exposed to challenging conditions, including fluctuating temperatures, moisture, and potential chemical exposure. Electrical copper bus bars’ resistance to corrosion means they can withstand these environmental factors without losing their conductivity or mechanical properties. This leads to fewer breakdowns, longer service life, and reduced maintenance costs. As a result, industries can rely on electrical copper bus bars to continue performing well over the long term, making them a smart investment for companies that need dependable electrical infrastructure.

Additionally, the durability of copper reduces the need for frequent replacements, which further lowers the cost of ownership and helps companies avoid the inconvenience of system downtime.

Thermal Conductivity and Heat Dissipation

Another significant benefit of electrical copper bus bars is their ability to dissipate heat efficiently. Copper is an excellent conductor of heat, which means it can quickly transfer and disperse heat generated by electrical current flowing through the bus bars. In industrial environments, electrical systems often generate a substantial amount of heat, and proper heat management is essential to prevent overheating and equipment damage.

Why It Matters:

The ability of electrical copper bus bars to manage and dissipate heat reduces the risk of overheating, which can lead to fires, electrical failures, or other dangerous conditions. In industries such as manufacturing, mining, or chemical processing, where high currents are required for machinery and equipment, the heat generated can be significant. Copper’s thermal conductivity helps ensure that the temperature of the bus bars remains within safe operating limits, maintaining system stability and safety.

By preventing excessive heat buildup, copper bus bars also reduce the likelihood of costly electrical failures, increasing the overall reliability of the power distribution system.

Strength and Mechanical Properties

Copper is not only known for its electrical and thermal properties but also for its impressive mechanical strength. Electrical copper bus bars are designed to withstand physical stress, such as vibration, impact, and tension, making them highly reliable even in challenging industrial environments.

Why It Matters:

Industrial settings often involve high levels of mechanical stress, whether it’s from heavy machinery, constant vibrations, or physical impacts. Electrical copper bus bars are robust enough to endure these conditions without compromising their performance. This strength ensures that copper bus bars remain intact, even under high load conditions, which is essential for preventing disruptions in power distribution and ensuring the safe operation of electrical systems.

The mechanical properties of copper also allow bus bars to handle heavy currents without warping, bending, or breaking, even when subjected to significant forces. This reduces the need for additional reinforcement or complex structural designs, saving both time and money during installation and maintenance.

Cost-Effectiveness in the Long Run

While the initial cost of copper may be higher than alternatives like aluminum, electrical copper bus bars are often more cost-effective in the long run. Copper’s durability, efficiency, and low maintenance requirements mean that businesses will save on repair costs, replacements, and energy losses over time.

Why It Matters:

In industries where the electrical system operates continuously and must be highly reliable, the long-term benefits of copper far outweigh the initial cost. Copper’s longevity reduces the frequency of system upgrades or replacements, while its superior conductivity lowers energy consumption. These savings can be significant, especially in industries with large power demands.

Furthermore, copper bus bars require less material to carry the same current as aluminum or steel, which means industries can achieve the same performance with a smaller, more compact design. This not only reduces installation costs but also saves on maintenance and energy consumption over the years.

Easy Customization and Fabrication

Copper is a highly malleable material, making electrical copper bus bars easy to fabricate into various shapes, sizes, and configurations to suit specific applications. Whether the requirement is for a compact, high-current distribution system or a larger, multi-panel setup, copper can be tailored to meet the unique needs of each installation.

Why It Matters:

Industries benefit from the flexibility that electrical copper bus bars offer in terms of customization. The ability to fabricate copper bus bars to specific dimensions and configurations ensures that they fit seamlessly into existing electrical systems. Whether it’s a new build or an upgrade to an existing infrastructure, customized copper bus bars can be integrated with minimal modifications, improving overall system efficiency.

Moreover, the ease of fabrication allows for quick adaptation to changing industrial needs, which is particularly useful in fast-paced industries where power requirements may evolve over time.

Enhanced Safety Features

Safety is always a top priority in industrial settings, and electrical copper bus bars play a crucial role in reducing electrical hazards. Copper’s superior conductivity ensures that electrical current flows smoothly and safely through the system, minimizing the risk of overheating, electrical shorts, or fires. Additionally, copper bus bars are often coated with insulating materials to further reduce the risk of accidental contact or short circuits.

Why It Matters:

In industries where electrical systems are integral to daily operations, ensuring the safety of employees and equipment is critical. The use of electrical copper bus bars significantly lowers the likelihood of electrical hazards, such as short circuits or power surges, which could lead to equipment damage or safety risks. By maintaining stable electrical flow and reducing the risk of overheating, copper bus bars enhance the overall safety of the system.

Furthermore, the durability of copper ensures that the bus bars continue to perform reliably, even in challenging conditions, which further minimizes the risk of accidents or system failures.

Environmental Sustainability

In today’s world, environmental sustainability is becoming an increasingly important consideration for industries. Copper is one of the most recyclable materials, and electrical copper bus bars are no exception. At the end of their lifecycle, copper bus bars can be recycled with minimal energy expenditure, making them an eco-friendly option for power distribution systems.

Why It Matters:

Industries that use electrical copper bus bars contribute to sustainability efforts by opting for a material that can be reused and recycled. Copper’s recyclability helps reduce the environmental impact of manufacturing new electrical components, leading to a smaller carbon footprint for companies. Additionally, because copper’s properties do not degrade during the recycling process, it can be reused multiple times without loss of quality, making it a truly sustainable choice for long-term applications.

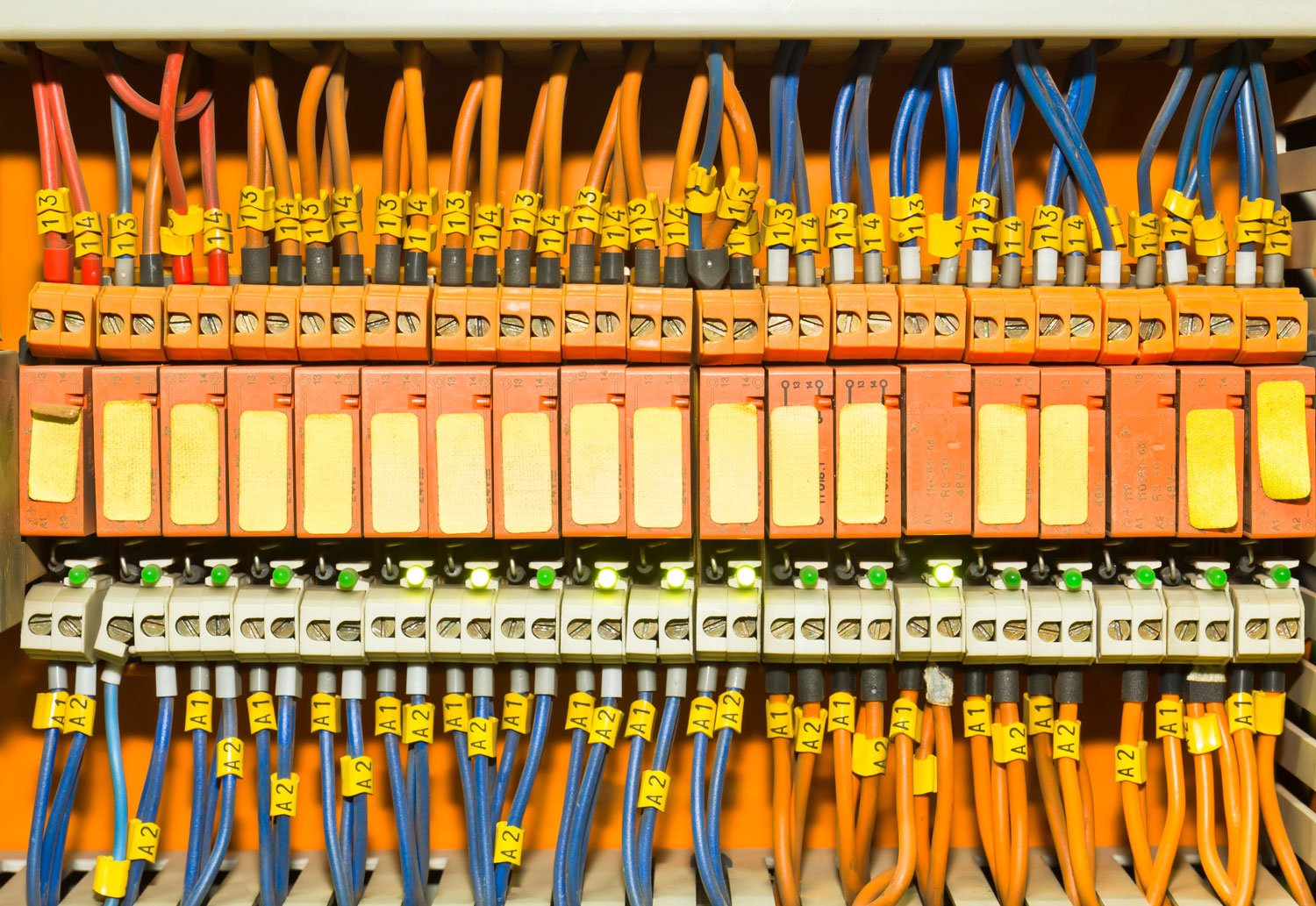

Compatibility with Other Electrical Components

Copper’s widespread use in the electrical industry means that electrical copper bus bars are compatible with a wide range of electrical components, such as connectors, terminals, and cables. This compatibility ensures that there are no issues when integrating copper bus bars into existing electrical systems.

Why It Matters:

For industries looking to expand or upgrade their electrical systems, electrical copper bus bars provide a seamless integration with other components. Whether upgrading an old system or designing a new one, copper bus bars ensure that all parts of the system work together harmoniously, reducing the likelihood of compatibility issues and system failures.

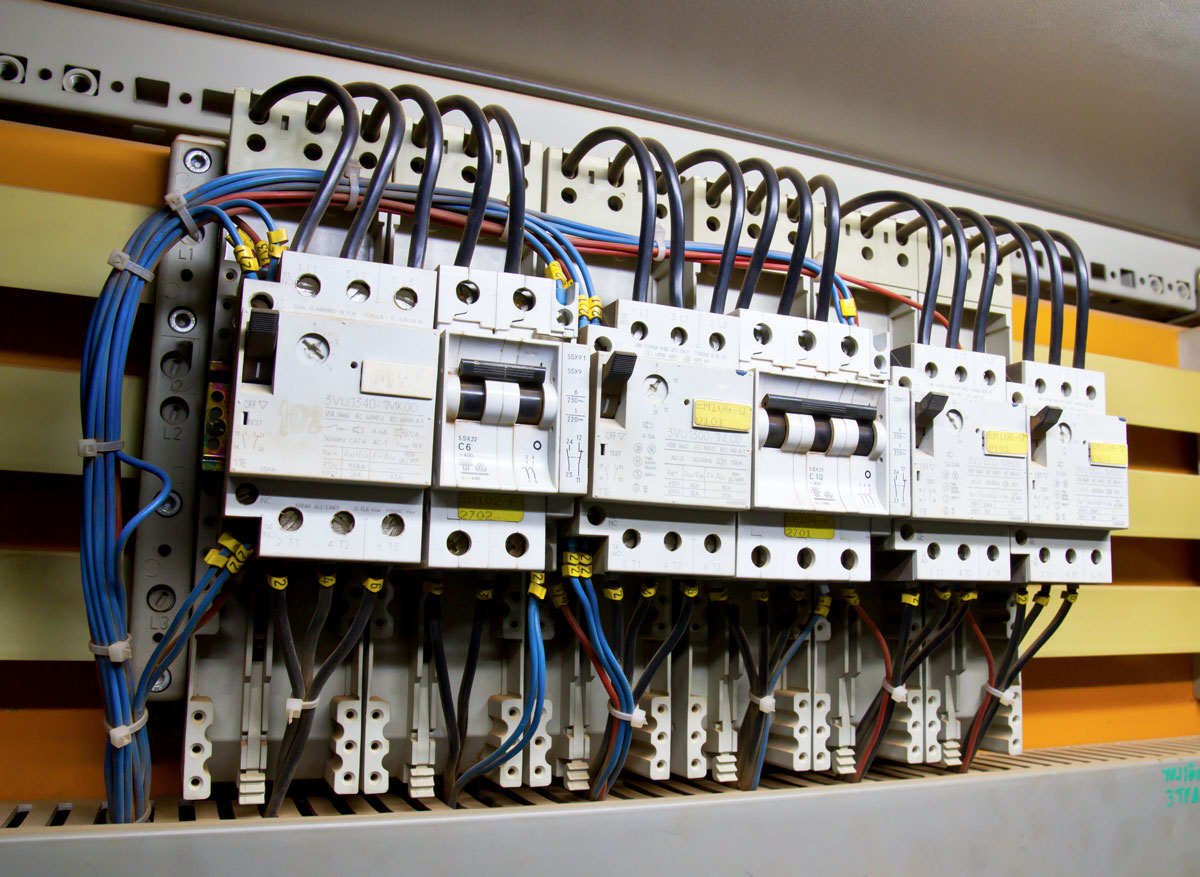

Support for High Current Density Applications

Finally, electrical copper bus bars are well-suited for high current density applications, which are common in industrial environments. Copper’s ability to handle significant electrical loads in a compact space allows industries to design more efficient, space-saving power distribution systems.

Why It Matters:

In industries where space is at a premium, electrical copper bus bars provide a compact yet highly efficient solution for power distribution. The ability to carry high currents in smaller cross-sections means that copper bus bars can be used in tight spaces without sacrificing performance. This is especially beneficial in environments like electrical control panels, switchgear rooms, and industrial machinery where space efficiency is a key consideration.

Conclusion

In conclusion, electrical copper bus bars offer numerous advantages for industrial settings, including superior electrical conductivity, durability, thermal management, and long-term cost-effectiveness. Their strength, safety features, and ability to integrate seamlessly with other components make them an ideal choice for industries that rely on reliable and efficient electrical systems.

By investing in electrical copper bus bars, businesses can optimize their electrical systems, reduce operational costs, enhance safety, and contribute to sustainability efforts. As industrial power demands continue to grow, the role of copper in electrical infrastructure will only become more critical, ensuring that copper remains a top choice for businesses that prioritize performance, reliability, and longevity.