The Essential Guide to Electrical Terminal Bus Bars

In any electrical system, efficiency and safety are paramount. Whether in industrial plants, power distribution systems, or commercial buildings, a key component that ensures smooth and reliable electrical connections is the electrical terminal bus bar. This unassuming piece of hardware plays a vital role in managing the flow of electricity by connecting multiple circuits and components in a system. Understanding how electrical terminal bus bars function, their types, applications, and installation methods is crucial for anyone involved in electrical engineering, construction, or maintenance.

This comprehensive guide will delve into the intricacies of electrical terminal bus bars, offering insights into their design, benefits, and best practices for installation and maintenance.

What is an Electrical Terminal Bus Bar?

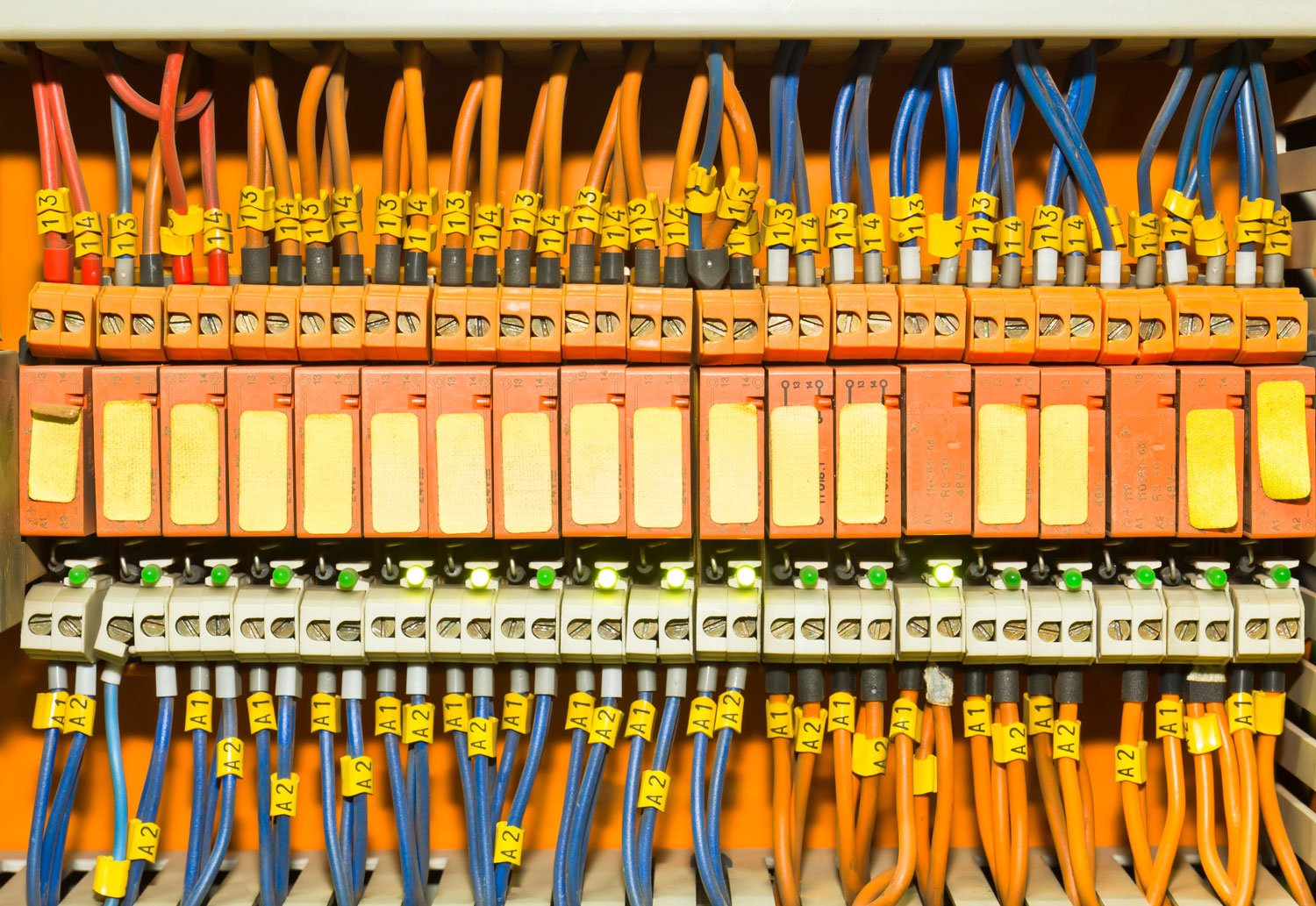

At its core, an electrical terminal bus bar is a conductive metal bar used to connect various electrical circuits. It serves as a central point where different wires, cables, and components can be attached to a single system. Bus bars are typically made from materials with excellent electrical conductivity, such as copper, aluminum, or brass, to ensure minimal resistance and heat generation.

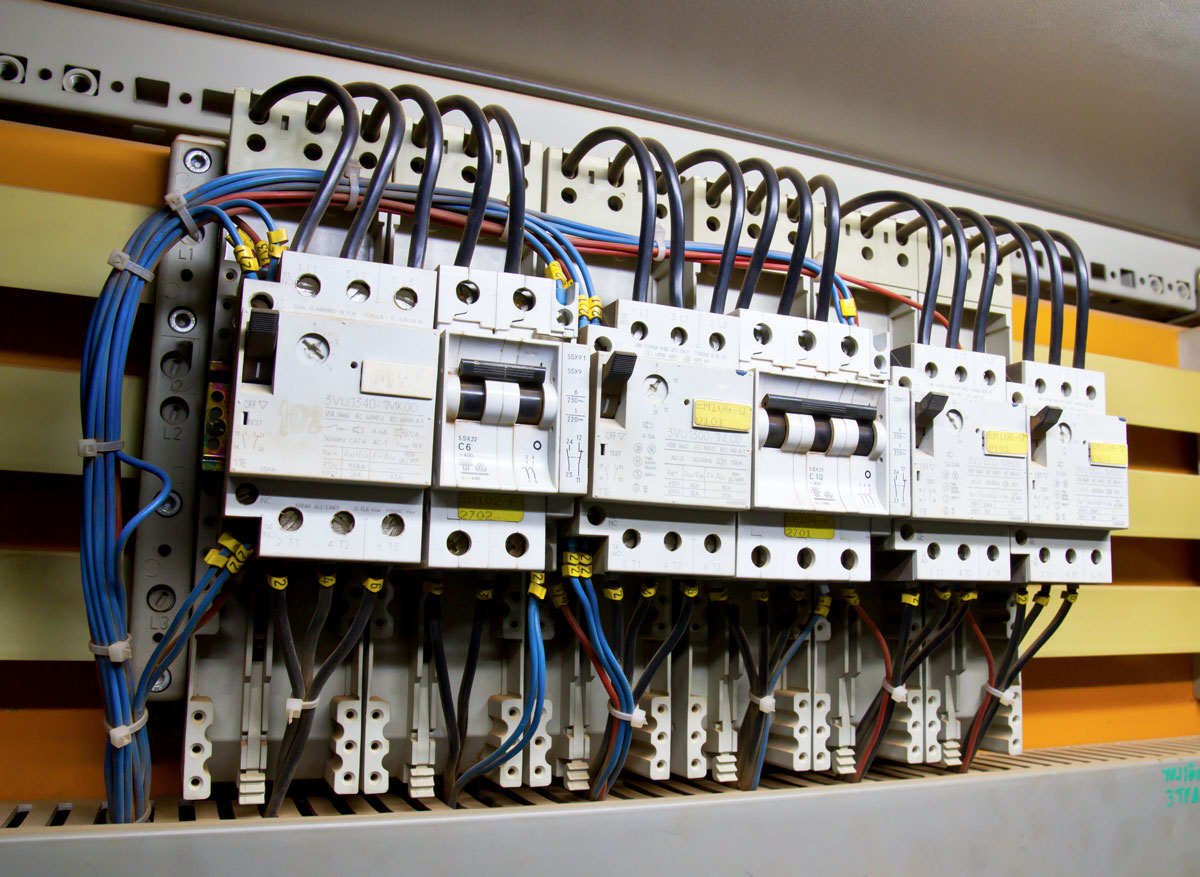

Electrical terminal bus bars are commonly used in distribution boards, electrical panels, switchboards, and other power distribution systems. Their primary function is to simplify the wiring process by offering a centralized location for electrical connections, thus reducing the complexity and bulk of wiring in a system.

Key Functions of Electrical Terminal Bus Bars

The electrical terminal bus bar serves several crucial functions within an electrical system, including:

- Power Distribution: By connecting multiple circuits to a single power source, bus bars facilitate efficient distribution of electrical power to various parts of a building or facility.

- Connection Hub: They act as a central hub for connecting incoming and outgoing cables, allowing for quick and easy installation and maintenance.

- Current Carrying: Electrical terminal bus bars are designed to carry significant amounts of current, which makes them ideal for high-power applications where multiple circuits need to be linked together.

- Short-Circuit Protection: By providing a reliable connection, bus bars help to minimize the risk of short circuits, which could potentially cause damage to equipment or pose safety hazards.

Types of Electrical Terminal Bus Bars

Not all electrical terminal bus bars are created equal. They come in various shapes, sizes, and materials to suit different applications. The primary types of electrical terminal bus bars include:

1. Solid Bus Bars

Solid bus bars are typically made from a single piece of conductive metal, such as copper or aluminum. They are widely used in high-power systems where a stable, continuous flow of electricity is required. Solid bus bars offer high current-carrying capacity and low electrical resistance, making them ideal for industrial and commercial applications.

2. Strip Bus Bars

Strip bus bars are flat, thin strips of metal that are often used in applications where space is limited. They are lighter and more flexible than solid bus bars, but they still offer excellent conductivity. Strip bus bars are typically used in smaller systems or in applications where compactness is essential.

3. Insulated Bus Bars

Insulated bus bars have a layer of insulating material (such as PVC or fiberglass) that surrounds the conductive metal. This insulation helps to prevent accidental contact with other conductive surfaces, reducing the risk of electrical shock. Insulated bus bars are commonly used in systems where safety is a top priority, such as in residential and commercial electrical panels.

4. Bus Bar Assemblies

Bus bar assemblies consist of multiple bus bars, connectors, and insulation materials combined into a single, pre-assembled unit. These are often used in large-scale electrical systems, such as substations or power plants, where multiple circuits need to be connected in an organized manner. Bus bar assemblies simplify installation and maintenance by reducing the need for on-site assembly.

5. Modular Bus Bars

Modular bus bars are designed to be customizable and flexible, allowing for easy expansion and reconfiguration of electrical systems. These bus bars consist of multiple modules that can be connected to each other, making them ideal for applications where future expansion or modification is anticipated.

Applications of Electrical Terminal Bus Bars

Electrical terminal bus bars are used in a wide range of applications across various industries. Some of the most common uses include:

1. Power Distribution Systems

In power distribution systems, bus bars are essential for ensuring the efficient transfer of electrical energy from a power source to various distribution points. They are used in substations, electrical panels, and switchboards to manage the distribution of power to different parts of a building or facility.

2. Industrial and Commercial Buildings

In industrial and commercial buildings, electrical terminal bus bars are used to connect multiple circuits to a central power source. This reduces the need for extensive wiring and simplifies the maintenance of electrical systems.

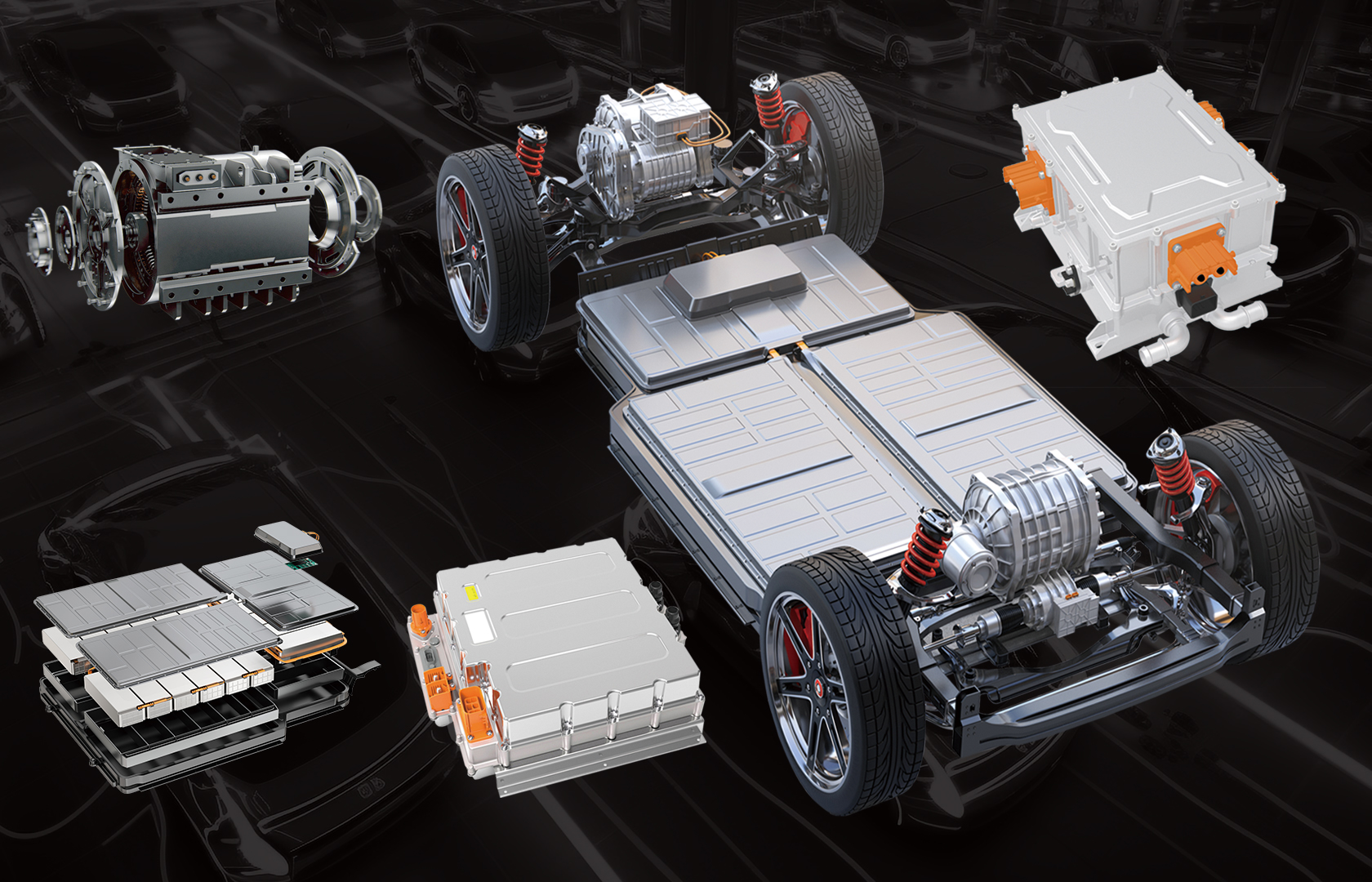

3. Renewable Energy Systems

In solar power systems, wind turbines, and other renewable energy setups, bus bars are used to connect various components of the system, such as inverters, batteries, and charge controllers. This helps streamline the wiring and enhances the overall efficiency of the system.

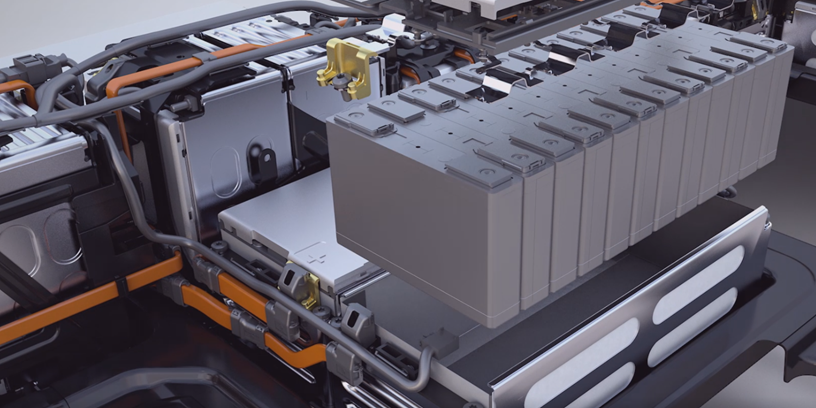

4. Automotive and Transportation

Bus bars are also used in automotive and transportation applications, particularly in electric vehicles (EVs). In these systems, bus bars connect high-voltage batteries, power distribution units, and other critical components, ensuring efficient power flow and reducing the overall size of the electrical system.

5. Telecommunication Systems

Telecommunication equipment requires reliable electrical connections to function correctly. Bus bars are often used in telecom panels and equipment racks to manage power distribution and simplify the connection of various devices.

Benefits of Using Electrical Terminal Bus Bars

There are numerous advantages to incorporating electrical terminal bus bars into electrical systems, including:

1. Space Efficiency

By centralizing electrical connections, bus bars help to reduce the clutter of wiring in electrical panels and systems. This makes it easier to manage and maintain the system while optimizing the use of available space.

2. Reduced Installation Time

Installing bus bars can significantly reduce the time required for wiring and connecting multiple circuits. With a bus bar, multiple connections can be made quickly and easily, reducing the complexity of installation.

3. Improved Safety

Bus bars improve safety by reducing the number of exposed wires and minimizing the risk of accidental short circuits. The use of insulated bus bars further enhances safety by preventing direct contact with live conductors.

4. Enhanced Reliability

By providing a stable and secure connection point, electrical terminal bus bars enhance the overall reliability of an electrical system. Their low resistance and ability to handle high currents ensure that the system remains operational even under demanding conditions.

5. Flexibility and Scalability

In modular and bus bar assembly configurations, electrical terminal bus bars allow for easy expansion and modification of an electrical system. This makes them ideal for applications where future growth or changes are anticipated.

Best Practices for Installing Electrical Terminal Bus Bars

Proper installation of electrical terminal bus bars is essential for ensuring optimal performance and safety. Here are some best practices to follow:

1. Ensure Proper Sizing

The size of the bus bar should be chosen based on the expected current load and the type of electrical system. Overloading a bus bar can lead to overheating, which can cause damage to the system or even lead to fires.

2. Use High-Quality Materials

Always choose bus bars made from high-quality conductive materials such as copper or aluminum. The quality of the material directly impacts the performance and longevity of the bus bar.

3. Proper Insulation

For safety, ensure that bus bars are adequately insulated, especially in high-voltage systems. Insulated bus bars should be used in environments where there is a risk of accidental contact with the conductive material.

4. Regular Maintenance and Inspection

To maintain optimal performance, bus bars should be inspected regularly for signs of wear, corrosion, or overheating. Regular cleaning and tightening of connections can prevent issues from arising.

Conclusion

Electrical terminal bus bars are indispensable components in modern electrical systems, providing a safe, efficient, and reliable means of distributing electrical power. From power plants to renewable energy systems, their applications are vast and varied, offering numerous benefits in terms of space efficiency, safety, and reliability. Understanding the different types, applications, and installation best practices for bus bars is essential for anyone working with electrical systems, whether in industrial, commercial, or residential settings.