The Importance of Insulated Flexible Busbars in EV Applications

As electric vehicles (EVs) continue to rise in popularity and prominence, the demands on their electrical systems have intensified. One critical component that has emerged as a cornerstone in the design of efficient and reliable EV electrical systems is the insulated flexible busbar. This blog delves into the significance, benefits, and applications of insulated flexible busbars in EVs, highlighting why they are pivotal to the future of electric mobility.

Understanding Insulated Flexible Busbars

Insulated flexible busbars are advanced electrical conductors that consist of multiple layers of conductive material, typically copper or aluminum, laminated together with an insulating layer. This construction allows for enhanced flexibility, durability, and electrical conductivity, making them ideal for the dynamic and high-power environments found in EVs.

Key Benefits of Insulated Flexible Busbars in EVs

-

Improved Electrical Performance:

-

Low Electrical Resistance: The multi-layered construction of insulated flexible busbars reduces electrical resistance, ensuring efficient power transfer within the EV's electrical system.

-

Enhanced Conductivity: The use of high-quality conductive materials such as copper or aluminum ensures optimal conductivity, minimizing energy losses and improving overall system efficiency.

-

-

Space and Weight Efficiency:

-

Compact Design: Insulated flexible busbars can be designed to fit into tight spaces, allowing for more compact and lightweight electrical system designs. This is particularly important in EVs, where space is at a premium.

-

Weight Reduction: Compared to traditional wiring and cabling systems, insulated flexible busbars are significantly lighter, contributing to the overall reduction in vehicle weight and enhancing energy efficiency.

-

-

Thermal Management:

-

Effective Heat Dissipation: The laminated structure of insulated flexible busbars facilitates better heat dissipation, preventing overheating and ensuring stable operation under high power loads.

-

Improved Reliability: By maintaining lower operating temperatures, insulated flexible busbars reduce the risk of thermal degradation and enhance the longevity and reliability of the EV's electrical components.

-

-

Enhanced Flexibility and Durability:

-

Mechanical Flexibility: The flexible nature of these busbars allows them to withstand the dynamic movements and vibrations experienced in EV applications, reducing the risk of mechanical failure.

-

Robust Construction: The insulation layer provides additional protection against environmental factors such as moisture, chemicals, and abrasion, ensuring long-term durability and reliability.

-

-

Safety and Compliance:

-

High Insulation Resistance: The insulating layer ensures high resistance to electrical leakage and short circuits, enhancing the safety of the EV's electrical system.

-

Compliance with Standards: Insulated flexible busbars are designed to meet stringent automotive standards and regulations, ensuring compatibility and safety in EV applications.

-

Applications of Insulated Flexible Busbars in EVs

-

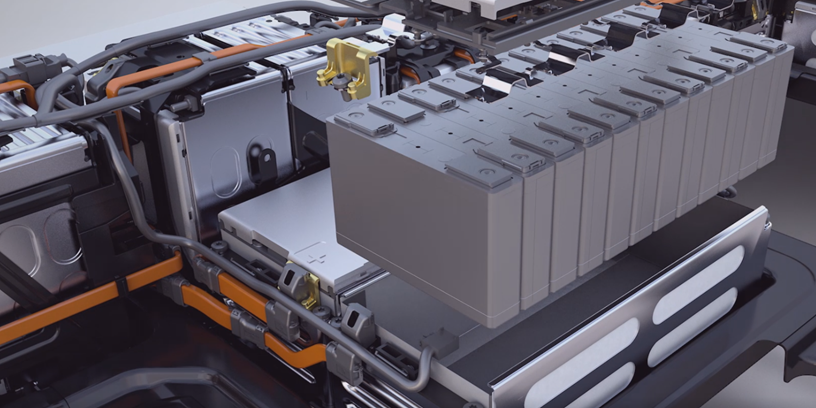

Battery Management Systems (BMS):

- Insulated flexible busbars play a crucial role in connecting battery cells and modules within the BMS. Their low resistance and high conductivity ensure efficient power distribution, while their flexibility allows for easy integration into compact battery packs.

-

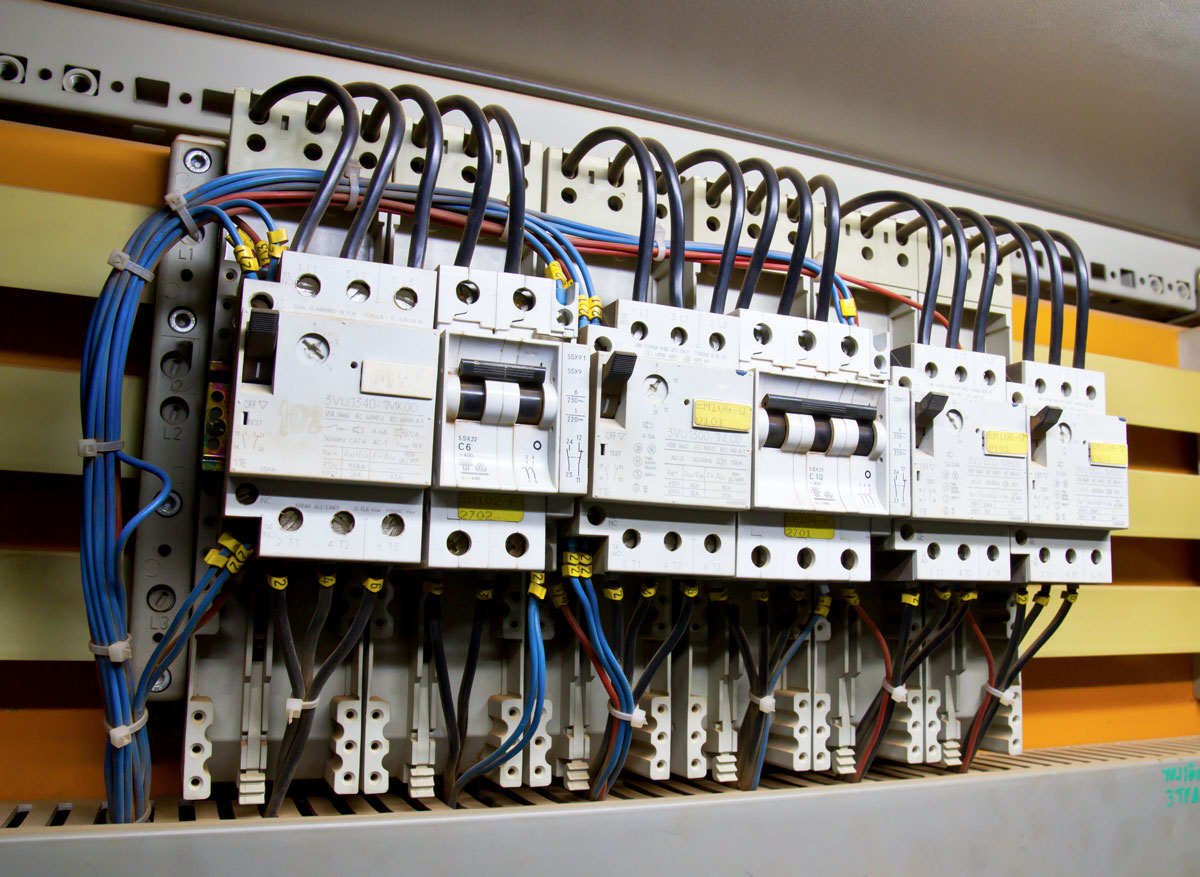

Power Distribution Units (PDU):

- PDUs are central to managing the distribution of electrical power throughout the EV. Insulated flexible busbars provide a reliable and efficient means of connecting various electrical components, such as inverters, chargers, and motors, within the PDU.

-

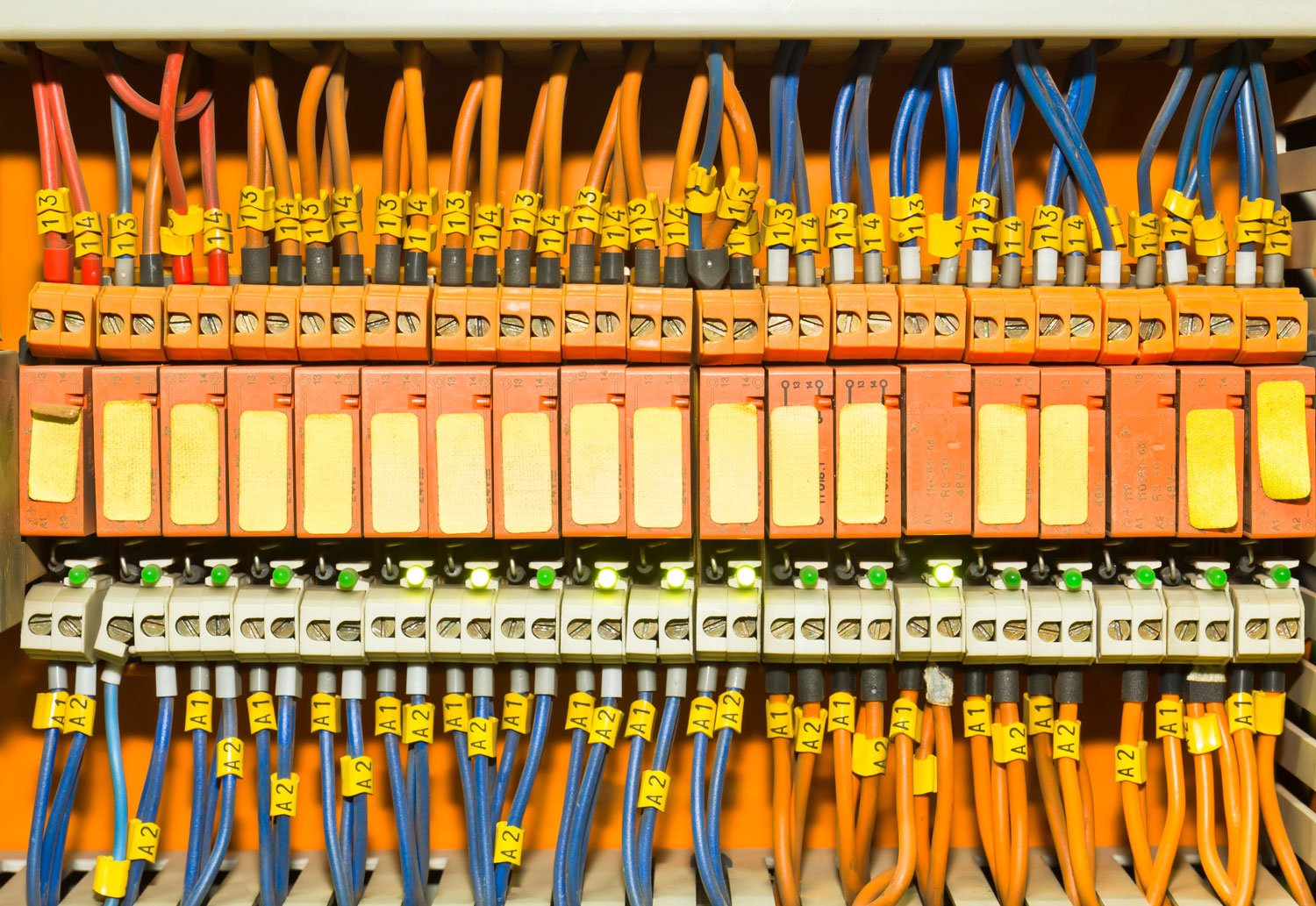

High-Voltage Interconnects:

- In high-voltage applications, such as connecting the battery pack to the motor or inverter, insulated flexible busbars offer superior performance compared to traditional wiring. Their ability to handle high currents and voltages with minimal losses makes them ideal for these critical interconnects.

-

Charging Systems:

- During charging, efficient power transfer is essential to minimize energy losses and reduce charging times. Insulated flexible busbars facilitate high-speed charging by providing low-resistance pathways for electrical currents, ensuring rapid and efficient energy transfer from the charger to the battery.

-

Inverter and Motor Connections:

- The connection between the inverter and the electric motor is vital for the performance of the EV's propulsion system. Insulated flexible busbars provide a robust and reliable connection, capable of handling the high currents and dynamic loads associated with electric motor operation.

Future Trends and Innovations

The rapid evolution of EV technology continues to drive advancements in insulated flexible busbar design and materials. Some of the future trends and innovations include:

-

Advanced Materials:

- Research into new conductive materials and improved insulation technologies promises to further enhance the performance and durability of insulated flexible busbars. These advancements will enable even greater efficiency and reliability in EV electrical systems.

-

Integration with Smart Systems:

- The integration of insulated flexible busbars with smart monitoring and diagnostic systems can provide real-time data on electrical performance, enabling predictive maintenance and enhancing the overall reliability of the EV.

-

Modular and Customizable Designs:

- The development of modular and customizable busbar designs will allow for greater flexibility in EV manufacturing, enabling manufacturers to tailor electrical systems to specific vehicle requirements and configurations.

-

Sustainability and Recycling:

- As the focus on sustainability grows, the development of eco-friendly materials and recycling processes for insulated flexible busbars will become increasingly important. This will ensure that the environmental impact of EV production and disposal is minimized.

Insulated flexible busbars are a vital component in the advancement of electric vehicles. Their superior electrical performance, space and weight efficiency, thermal management capabilities, and enhanced durability make them indispensable in the design of modern EV electrical systems. As technology continues to evolve, the role of insulated flexible busbars in EV applications will only become more significant, driving the future of electric mobility towards greater efficiency, reliability, and sustainability. Embracing these innovations will be key to unlocking the full potential of electric vehicles and achieving a cleaner, greener transportation future.