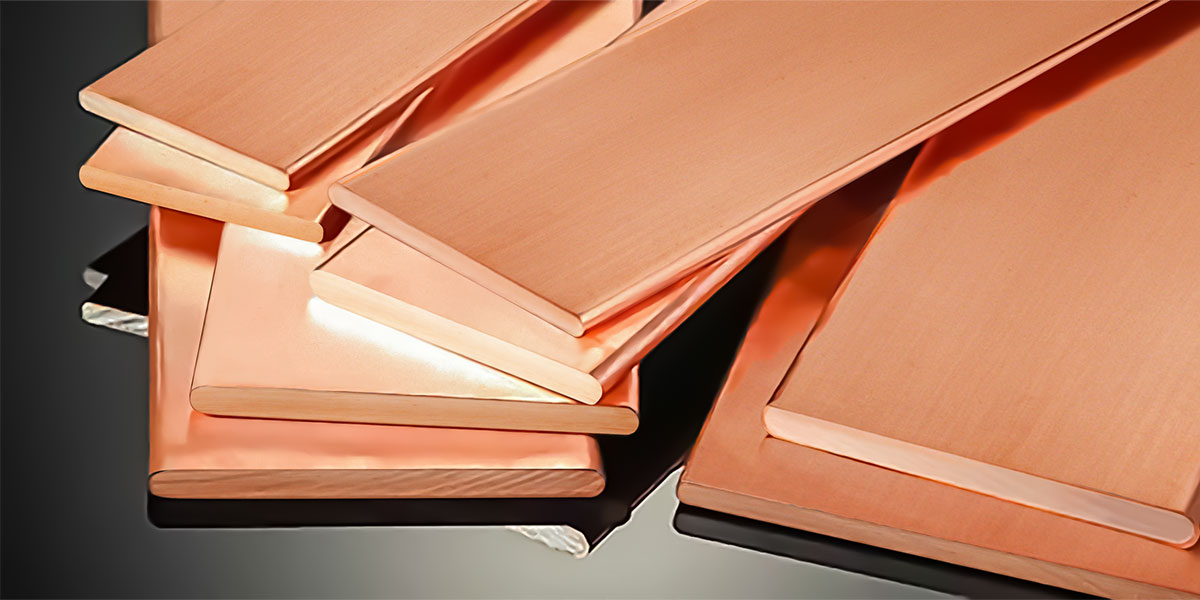

What Are the Grades of Copper Busbars?

Copper busbars come in various grades, each offering distinct properties tailored to specific applications. The grades are primarily distinguished by their chemical composition and mechanical properties. Here are some common grades of copper used for busbars:

1. Electrolytic Tough Pitch (ETP) Copper (C11000)

-

Composition: Over 99.9% pure copper with trace amounts of oxygen.

-

Properties:

-

High electrical conductivity (around 101% IACS - International Annealed Copper Standard).

-

Good mechanical strength.

-

Standard grade for most electrical applications.

-

-

Applications: General electrical and power distribution systems, switchgear, and panel boards.

2. Oxygen-Free High Conductivity (OFHC) Copper (C10200)

-

Composition: Over 99.95% pure copper with very low oxygen content (typically <0.001%).

-

Properties:

-

Superior electrical conductivity (around 101% IACS).

-

Excellent thermal conductivity.

-

High ductility and malleability.

-

-

Applications: High-frequency and high-reliability applications, such as vacuum tubes, particle accelerators, and high-quality audio systems.

3. Deoxidized High Phosphorus (DHP) Copper (C12200)

-

Composition: Copper with a small amount of phosphorus (0.015% - 0.040%).

-

Properties:

-

Lower electrical conductivity (around 85-90% IACS).

-

Improved corrosion resistance.

-

Good formability and weldability.

-

-

Applications: Plumbing, heating, and industrial applications where welding and brazing are required.

4. Chromium Copper (C18200)

-

Composition: Copper with small amounts of chromium (0.4% - 1.2%).

-

Properties:

-

High strength and hardness.

-

Good electrical conductivity (around 80-90% IACS).

-

Enhanced wear resistance.

-

-

Applications: Heavy-duty electrical connectors, welding electrodes, and components requiring high strength and conductivity.

5. Beryllium Copper (C17200)

-

Composition: Copper with 1.8% - 2% beryllium.

-

Properties:

-

Exceptional strength and hardness.

-

Good electrical conductivity (around 45-60% IACS).

-

Excellent thermal conductivity.

-

-

Applications: Spring contacts, connectors, and components requiring a combination of high strength and moderate conductivity.

6. High Conductivity Copper (HC)

-

Composition: Pure copper (99.99%).

-

Properties:

-

Extremely high electrical and thermal conductivity (around 101% IACS).

-

High purity level with very low levels of impurities.

-

-

Applications: Specialized electrical and electronic applications where maximum conductivity is essential.

The choice of copper grade for busbars depends on the specific requirements of the application, including electrical conductivity, mechanical strength, corrosion resistance, and thermal properties. Electrolytic Tough Pitch (ETP) Copper (C11000) is the most commonly used grade for general electrical applications, while other grades like OFHC Copper (C10200) and Chromium Copper (C18200) are chosen for specialized needs requiring superior conductivity and strength. Understanding the properties of each grade ensures the selection of the most suitable material for efficient and reliable electrical power distribution.