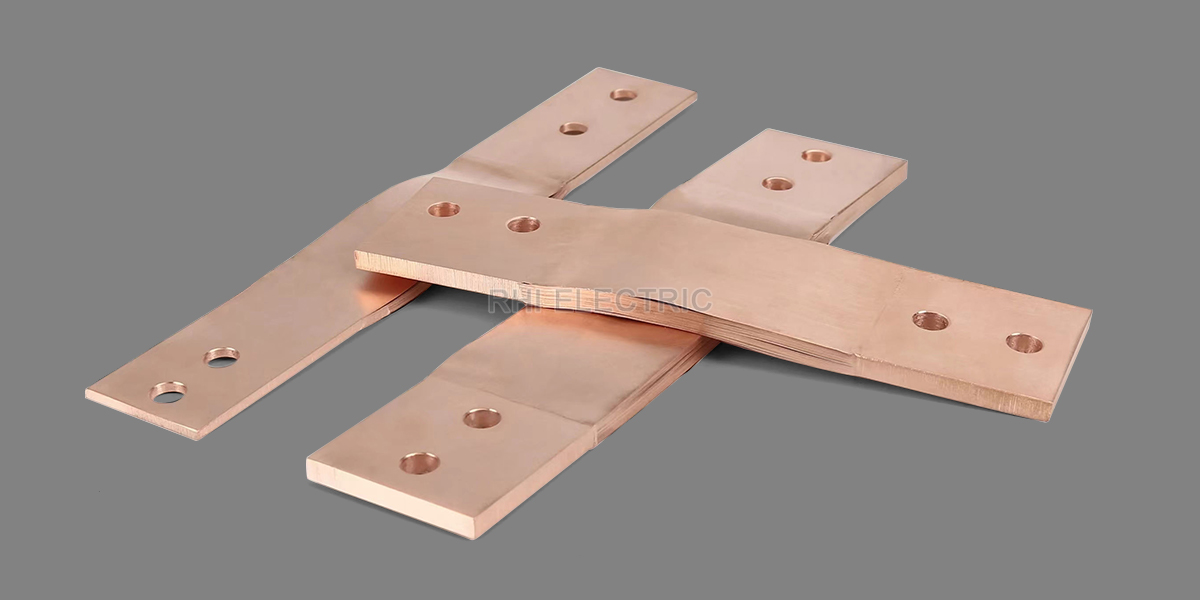

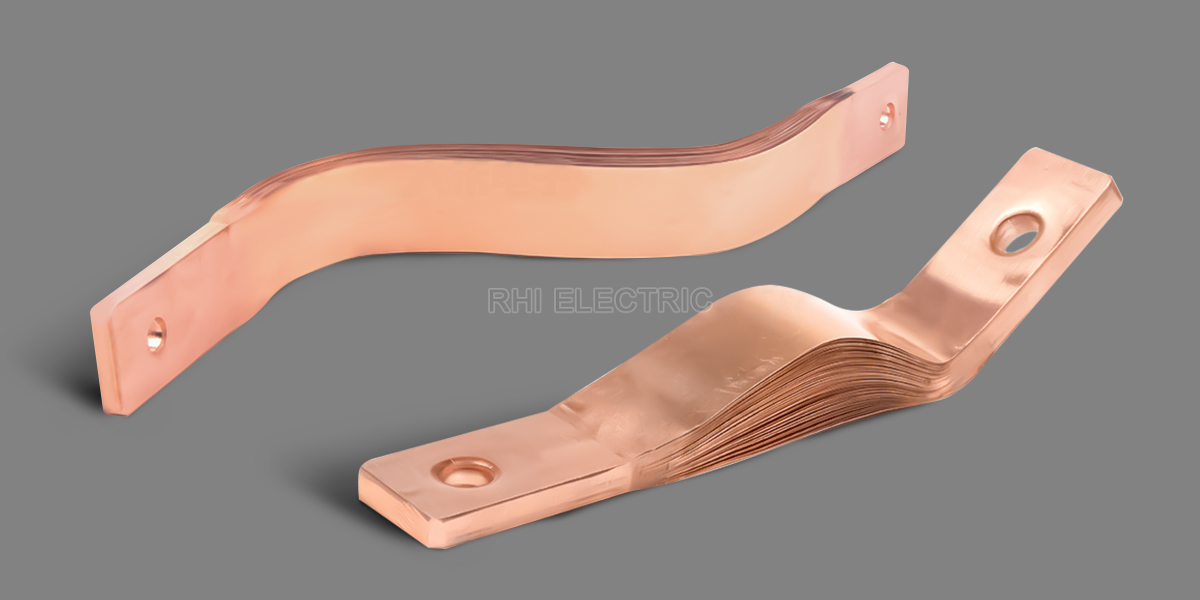

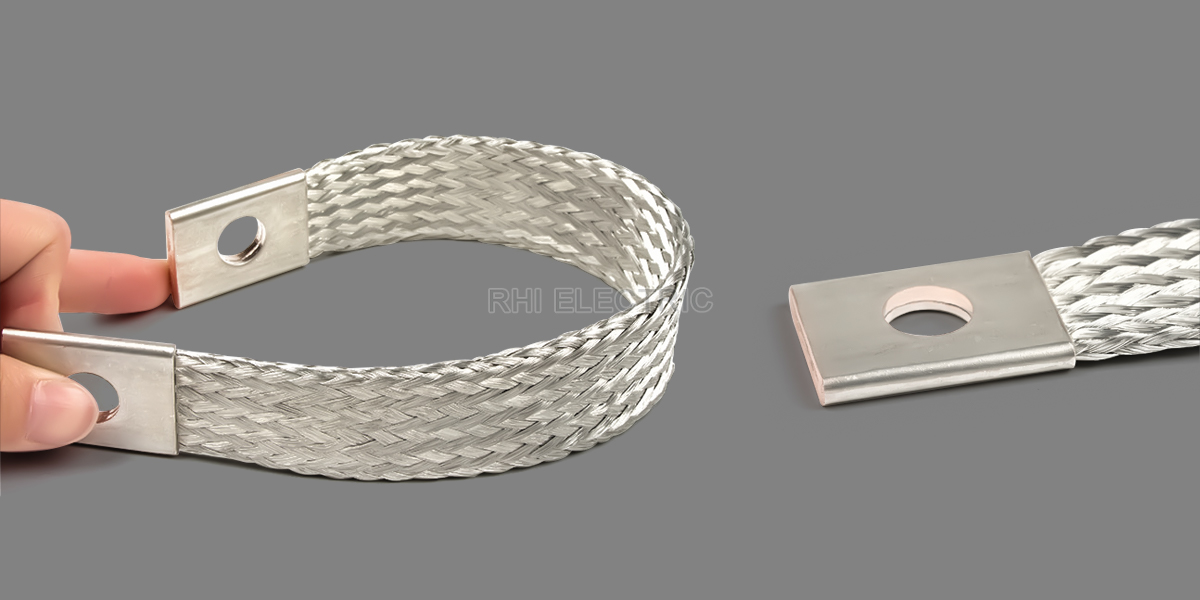

Flexible Copper Shunts

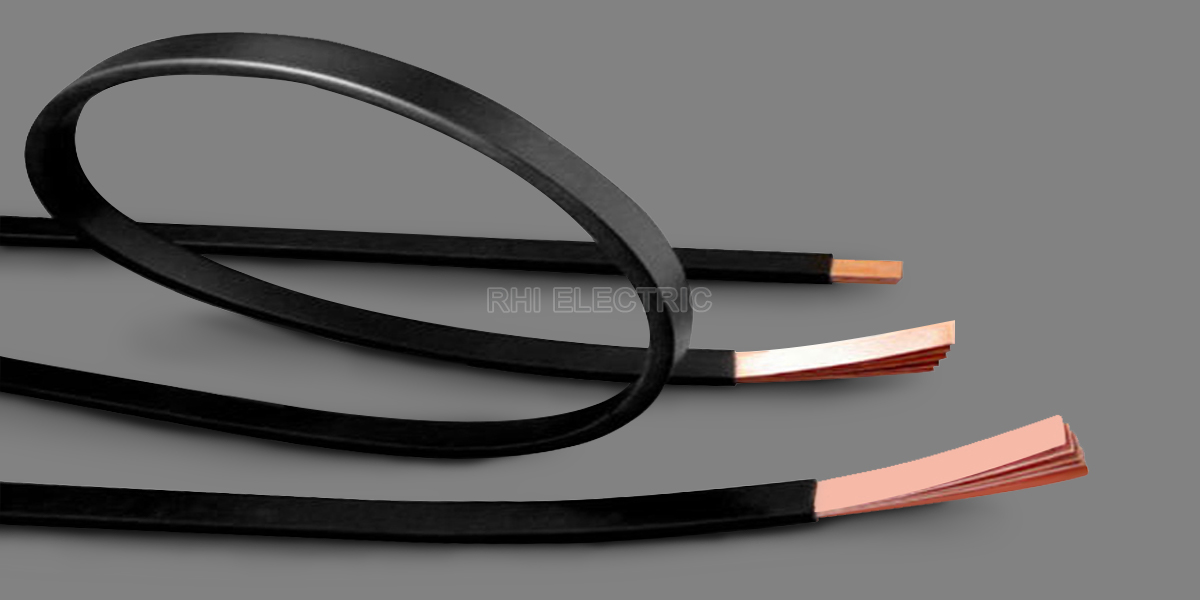

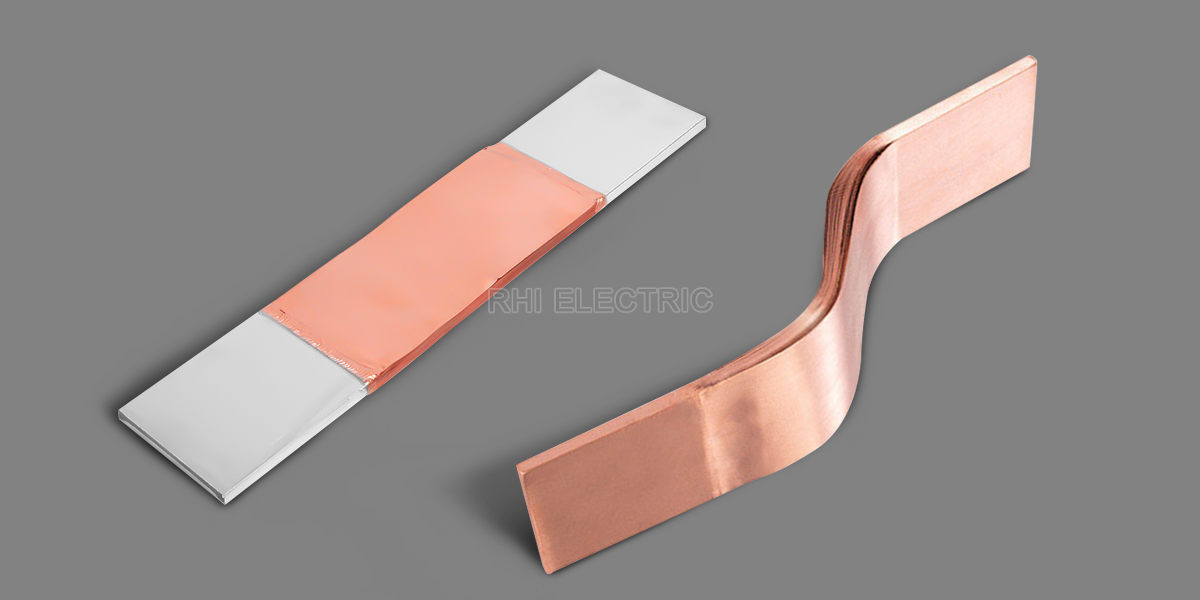

Flexible expansion busbars play an Important Role in Cost Reduction & Efficiency Improvement. Copper shunts serve to expand & compensate for vibrations in busbar connections. They also act as flexible current transmission elements in machine parts, vehicles, and switchgear. Flexible bus bars use diffusion welding for connections, allowing for versatile design options such as fixing with drilled holes.

Advantage of Copper Shunts

-

Thermal Expansion: Busbars can expand & contract due to temperature changes. Expansion joints accommodate this movement, reducing the stress on the busbars & preventing damage. These joints maintain optimal busbar condition, improving efficiency, preventing power losses, and enhancing reliability. This helps to extend the lifespan of the busbars.

-

Flexibility: Expansion busbars provide flexibility, allowing for slight movements in the busbar connections. This flexibility can help to absorb vibrations & shocks, reducing the risk of damage to the busbars and other connected equipment.

-

Installation: Using flexible shunts can simplify the installation process by eliminating the need for precise alignment of busbar sections. This can save time & reduce labor costs during installation.

-

Maintenance: By reducing stress on the busbars, expansion joints can help to minimize the need for maintenance & repairs, further reducing costs over the lifespan of the system.

Click here to view RHI's automated polymer welding process.

Features

- Material: Cu/Al strip or foil

- Surface Treatment: Nickel laminate, tin plating, silver plating, etc.

- The flexible connection is insulated with heat shrink tubing

- Installation flexibility and adaptability

- Good conductivity, flexibility, heat dissipation, and shock absorption

|

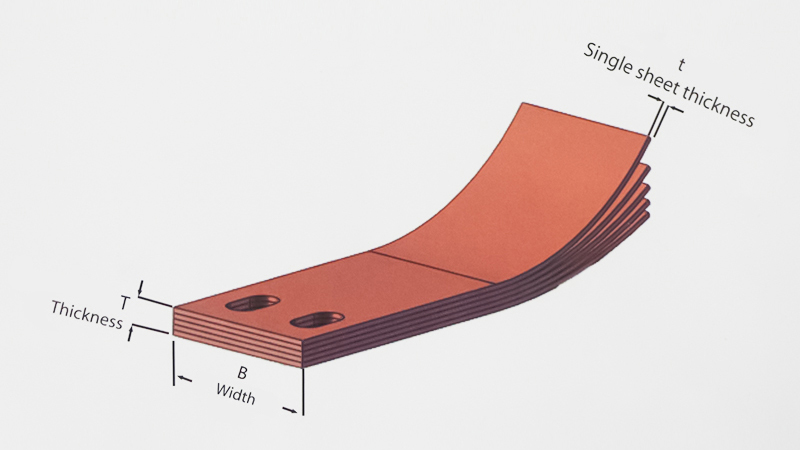

Material |

Single Sheet Thickness(t) |

Width(B) |

Thickness(T) |

||||||||

|

T2M Cu strip |

0.1 |

13 |

14 |

15 |

16 |

17 |

18 |

20 |

23 |

25 |

1~10 |

|

Al strip |

0.2 |

18 |

22 |

28 |

30 |

35 |

40 |

45 |

48 |

60 |

1~10 |

Application

Copper expansion joints feature excellent flexibility, heat dissipation, and shock absorption, specifically designed to accommodate minor displacements and thermal expansion in electrical systems. They effectively absorb stress caused by thermal expansion or equipment movement, reducing mechanical load on busbars and extending their lifespan.

Compared to rigid connections, expansion joints have lower installation precision requirements, simplifying the assembly process and reducing maintenance costs. Their efficient heat dissipation design ensures stable operation of the system under high current and high-temperature conditions. The flexible design makes copper expansion joints particularly suitable for dynamic connections in battery packs and energy storage systems, ensuring reliable power transmission.