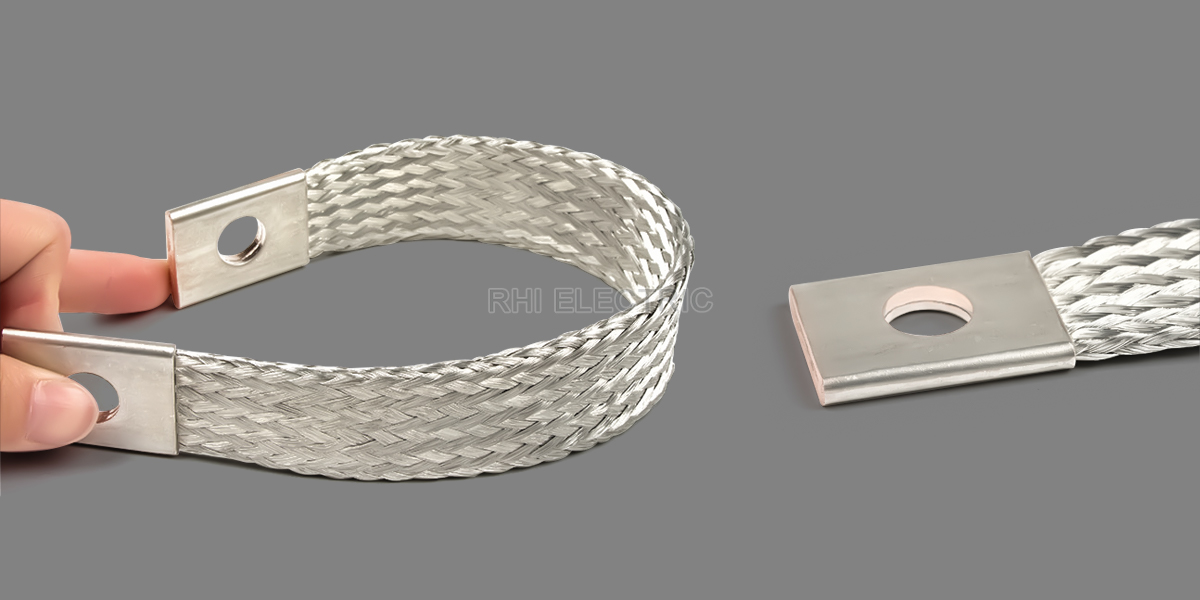

Braided Copper Busbars

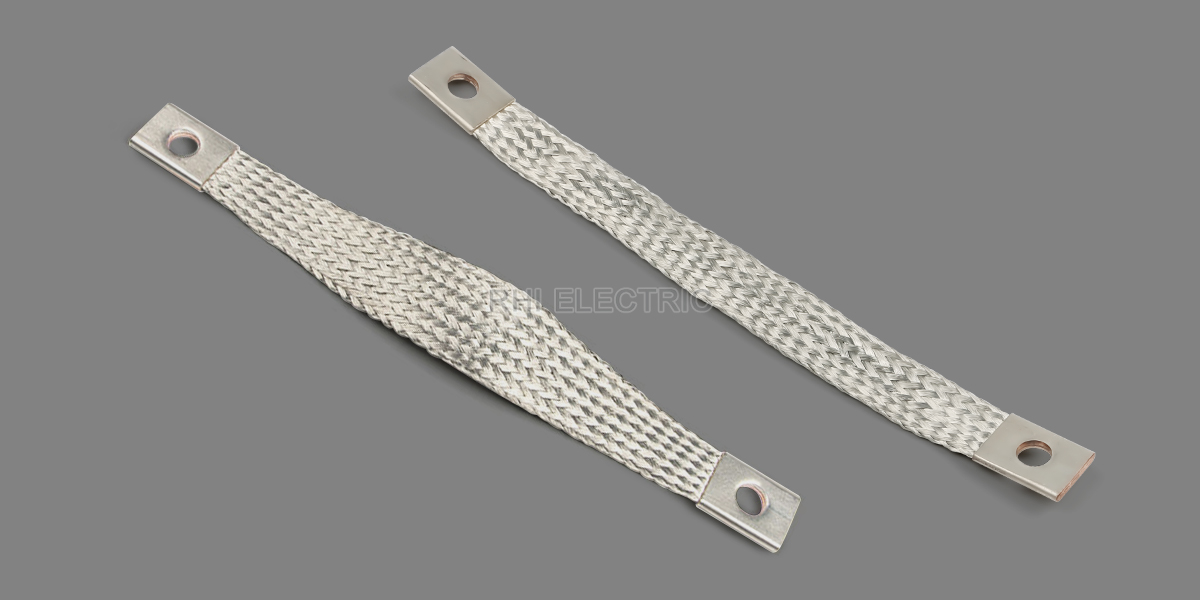

As a crucial component in electrical systems, the Braided Busbar offers improved flexibility, conductivity, vibration resistance, and heat dissipation due to its unique braided design. It can be customized in various types and sizes to meet client specifications.

RHI’s Braided Copper Busbars offer a high-performance, flexible, and reliable solution for modern electrical systems. Designed for superior conductivity and robust performance, these busbars are ideal for applications in power distribution, industrial automation, renewable energy systems, and high-current electrical installations. Our braided copper busbars combine the exceptional properties of copper with an innovative braided design, ensuring both flexibility and durability in challenging environments.

Additionally, the braided construction enhances vibration resistance, making it ideal for environments with frequent mechanical stress, such as electric vehicles, industrial machinery, and renewable energy systems. Its capacity for heat dissipation further improves operational stability, preventing overheating in high-current applications.

Product Details

|

Conductor Material: |

T2 Copper Copper Purity: ≥99.9% |

|

Diameter of the Copper Wires: |

0.20mm; 0.15mm (standard); 0.10mm; 0.05mm (available according to customers' requirement). |

|

Surface Treatment: |

Uncoated or tinned. |

|

Process: |

Solderless cold-pressed. |

|

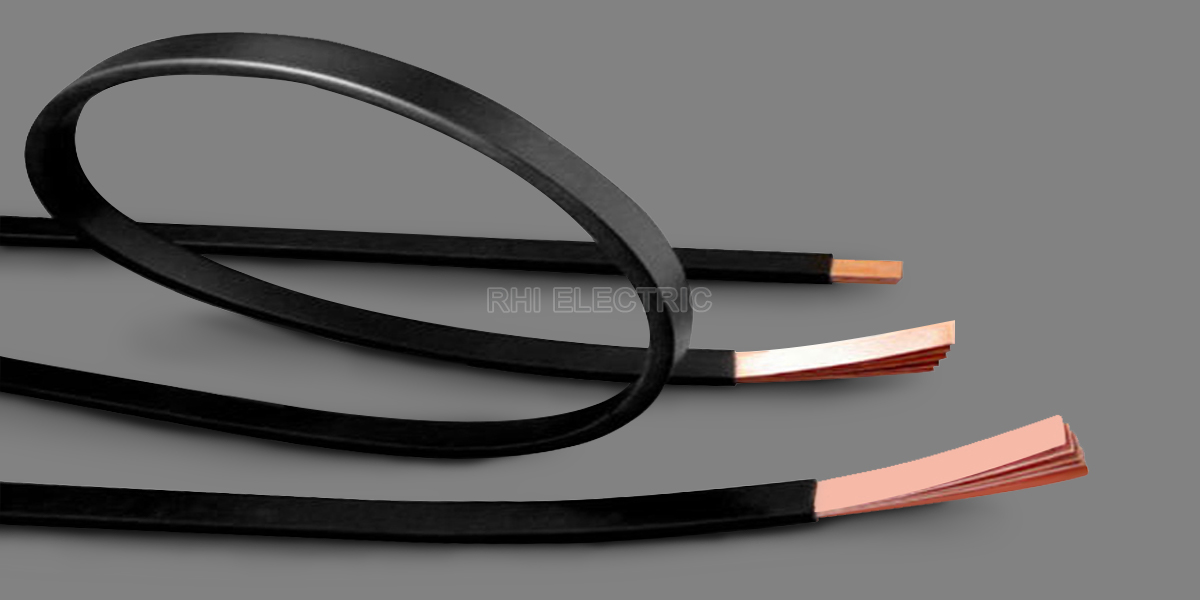

Insulation: |

The flexible part can be insulated using Heat Shrink Tube. |

|

Surface Treatment: |

Nickel Plating |

|

Enterprise Certificate: |

IATF16949, ISO45001, ISO14001 |

|

Quote Response Time: |

After receiving the drawings and verifying their feasibility, it will take 5-7 days to make a quotation. |

|

Delivery Time: |

The delivery time will take about 15-20 days after payment. |

|

Application: |

Transformers, distribution cabinets, new energy battery packs, electric vehicle motor connections, communication base stations, wind power systems, photovoltaic systems etc. |

Key Features

Superior Electrical Conductivity

- High Purity Copper: Manufactured from premium-grade copper, our braided busbars provide excellent electrical conductivity, ensuring minimal energy loss and optimal performance.

- Low Resistance: The braided structure offers increased surface area for current flow, reducing resistance and enhancing the efficiency of power transmission.

Enhanced Flexibility & Durability

- Braided Design: The interwoven copper strands create a flexible yet robust structure that can accommodate movement, vibration, and thermal expansion, making them perfect for dynamic installations.

- Resilient Construction: Designed to withstand mechanical stress and repeated bending, these busbars maintain their integrity over time, ensuring long-term reliability.

Efficient Thermal Management

- Effective Heat Dissipation: The high thermal conductivity of copper, combined with the braided architecture, promotes efficient heat distribution, preventing hotspots and extending the lifespan of connected components.

- Stable Operating Temperatures: Optimal thermal management contributes to consistent performance even under heavy load conditions.

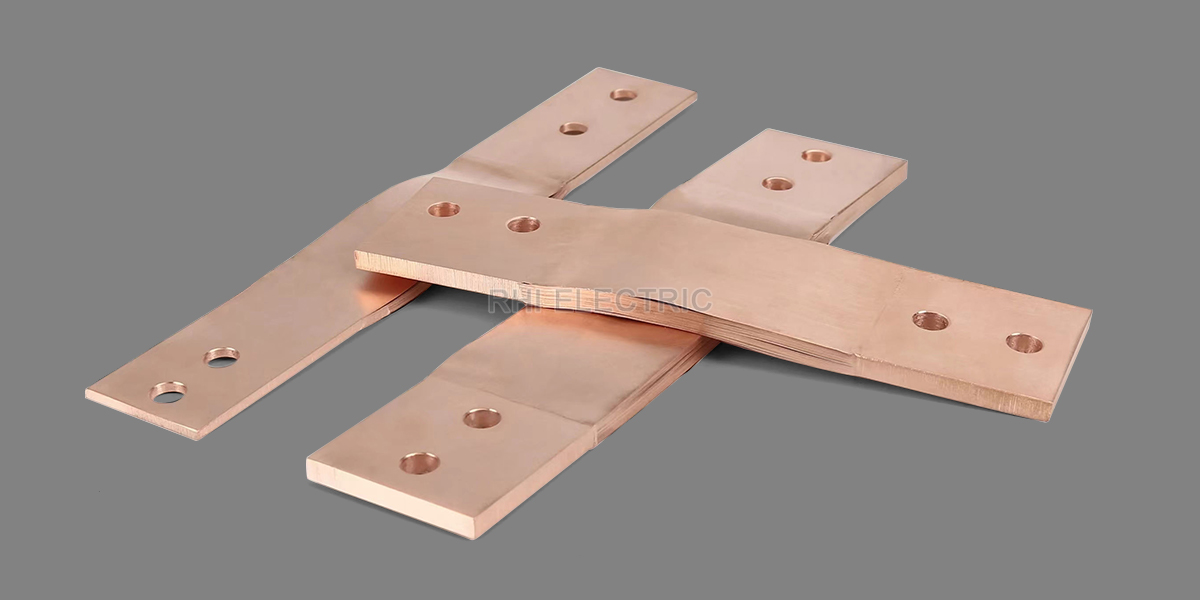

Customization & Versatility

- Tailor-Made Solutions: RHI offers customized braided copper busbar designs to meet specific project requirements, including various shapes, sizes, and configurations.

- Wide Range of Applications: Suitable for both low and high-current applications, our busbars are used in power distribution panels, switchgear, renewable energy installations, industrial machinery, and more.

Benefits

- Increased Reliability: The robust braided structure ensures continuous and stable power transmission, reducing downtime and maintenance costs.

- Enhanced Safety: With superior electrical performance and efficient heat management, our braided copper busbars help mitigate the risk of overheating and electrical faults.

- Energy Efficiency: Reduced resistance and optimal conductivity translate to lower energy losses and improved system efficiency.

- Flexibility in Installation: The adaptable design allows for easy integration into complex or confined spaces, making them a versatile solution for modern electrical systems.

Technical Specifications

While the technical specifications can be customized based on client needs, typical parameters include:

- Material: High-purity copper

- Conductivity: 100% IACS (International Annealed Copper Standard)

- Design: Braided, multi-strand configuration

- Operating Temperature: Optimized for high-performance heat dissipation

- Customization Options: Available in various sizes, lengths, and configurations to suit diverse applications

For detailed technical datasheets and custom configuration options, please contact our technical support team.

Applications

Braided Copper Busbars from RHI are ideally suited for:

- Power Distribution Systems: Reliable and efficient power transfer in substations, switchgear, and electrical panels.

- Industrial Automation: Robust busbars that can handle heavy-duty applications in manufacturing plants and automated systems.

- Renewable Energy Installations: Enhancing the efficiency of solar, wind, and energy storage systems with optimal conductivity and heat management.

- High-Current Applications: Ideal for systems requiring stable performance under high electrical loads, such as data centers and electric vehicle charging stations.

- Vibration-Prone Environments: Their flexible design makes them perfect for applications in rail transit, aerospace, and other dynamic systems.

Why Choose RHI?

- Proven Expertise: With years of industry experience, RHI is a trusted supplier of high-quality braided copper busbars.

- Custom Solutions: We understand that every project is unique. Our engineering team works closely with you to design custom busbar solutions tailored to your specific needs.

- Quality Assurance: Our products undergo rigorous quality control to ensure they meet international standards and deliver exceptional performance.

- Exceptional Customer Service: From consultation to post-installation support, RHI is dedicated to providing comprehensive service and technical expertise.

- Innovative Technology: Leveraging advanced manufacturing processes, we continually innovate to deliver products that exceed industry standards in reliability and efficiency.