Flexible Copper Busbar Insulated

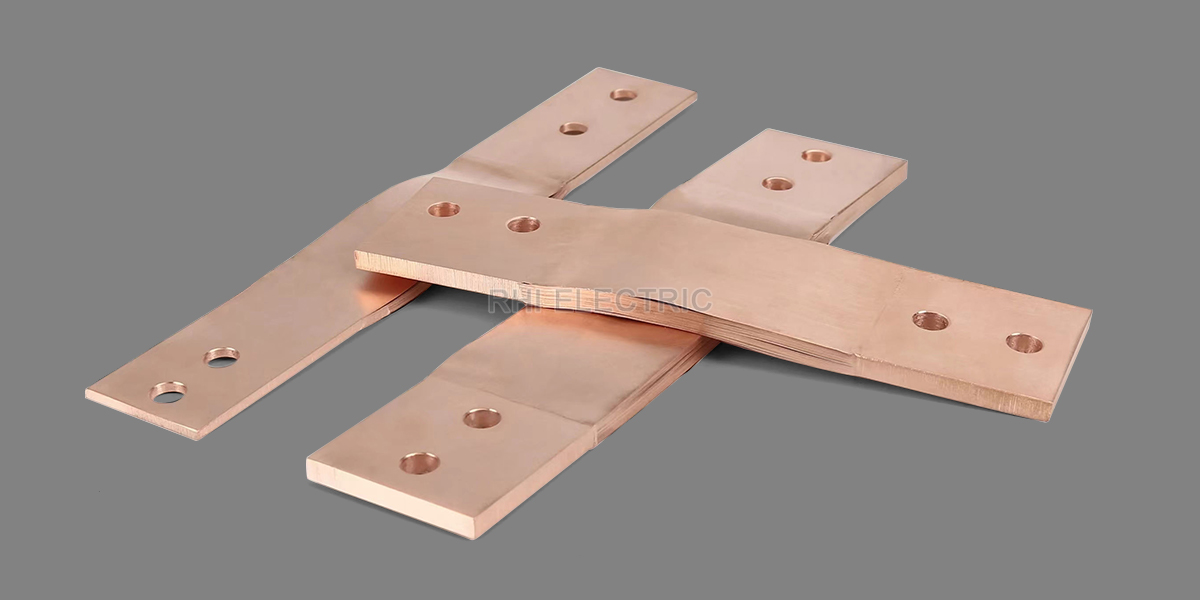

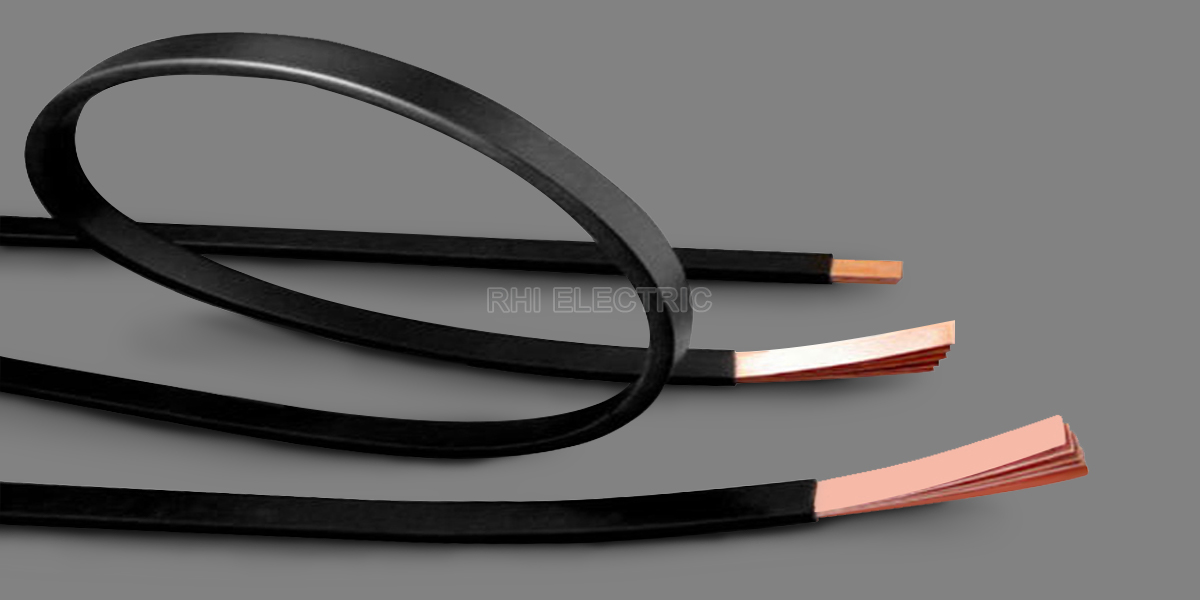

Flexible bus bars, made of multi-layer thin electrolytic copper, provide excellent conductivity, heat dissipation, and vibration absorption. Copper bus bars insulated with heat shrink tubing, are widely used for power connections in electric vehicles, transformers, and panel boards.

Heat shrink tubing, when heated, conforms tightly to busbar shapes, providing a uniform and robust insulation layer. It is easy and clean to install, requiring no soaking or drying time, and offers electrical insulation, moisture resistance, corrosion protection, and mechanical damage prevention. Cable ties help organize wiring, prevent friction between electrical busbars and other cables, facilitate maintenance and inspection, and extend the lifespan of the busbars.

Product Details

|

Conductor Material: |

Cu/Al Strip or Foil T2 (E-CU58, CU-ETP, C11000, C1100) TU2 (OF-CU, CU-OFE, CU-OF, C10100, C1011) Aluminium (1060) Or other materials per your request. |

|

Welding Process: |

Butt Welding/ Lap Welding |

|

Insulating Material: |

Heat Shrink Tubes: PE/ EVA Insulation |

|

Surface Treatment: |

Nickel/ Tin/ Silver plated or as your request. Plating Thickness: Normally 3um to 12um Or upon customers' request. |

|

Flame Retardant: |

UL94V-0 |

|

Punch Hole Design: |

Holes are punched through the laminated foils and can be round or oblong as requested. |

|

Enterprise Certificate: |

IATF16949, ISO45001, ISO14001 |

|

Eco-friendly Certificate: |

RoHS, REACH |

|

Quote Response Time: |

After receiving the drawings and verifying their feasibility, it will take 5-7 days to make a quotation. |

|

Delivery Time: |

The delivery time will take about 15-20 days after payment. |

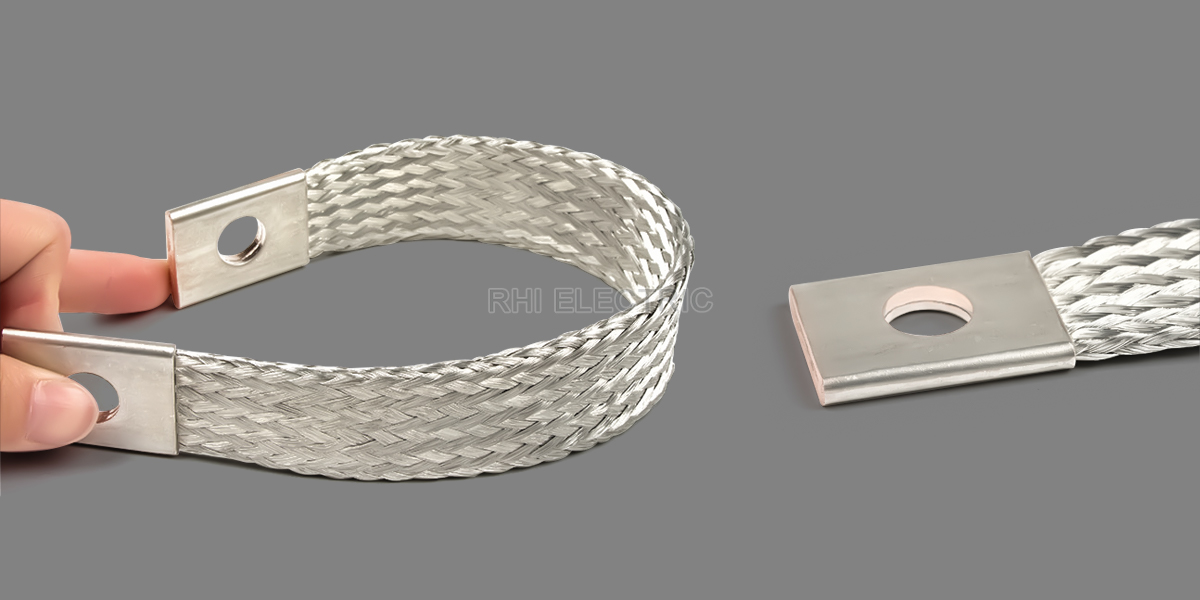

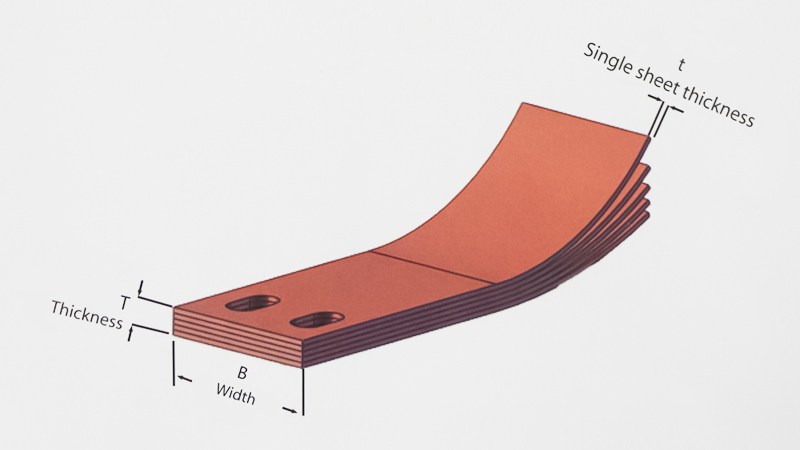

The busbar conductor is composed of multiple layers of electrolytic copper sheets, with both ends joined using diffusion welding technology. This construction provides excellent electrical conductivity along with outstanding flexibility and resilience.

Diffusion welding creates a strong, low-resistance connection that effectively minimizes the impact of stress from displacement, thermal expansion, and vibration. This reduces fatigue and structural damage under high-temperature or heavy-load conditions, thereby extending the busbar's lifespan and ensuring stable operation of the electrical system. Such designs are widely used in high-reliability electrical systems, including electric vehicles and energy storage applications.

|

Material |

Single Sheet Thickness(t) |

Width(B) |

Thickness(T) |

||||||||

|

T2M Cu strip |

0.1 |

13 |

14 |

15 |

16 |

17 |

18 |

20 |

23 |

25 |

1~10 |

|

Al strip |

0.2 |

18 |

22 |

28 |

30 |

35 |

40 |

45 |

48 |

60 |

1~10 |

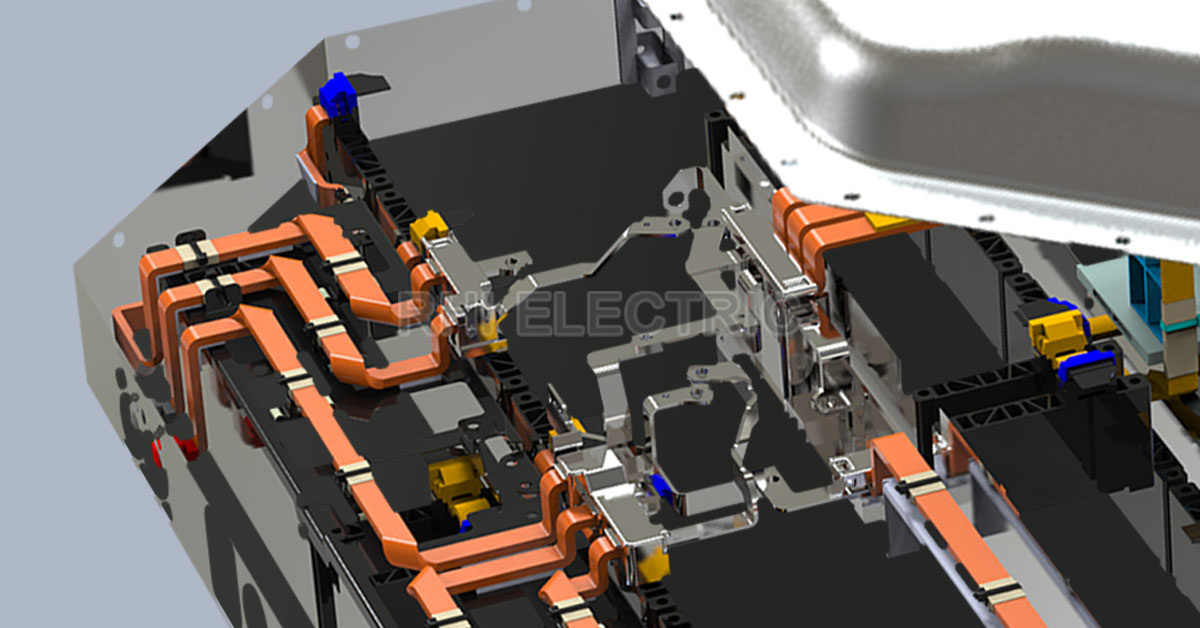

Application

Flexible busbars made from multi-layer electrolytic copper provide excellent conductivity, heat dissipation, and vibration absorption, making them ideal for EV power systems. Insulated with heat shrink tubing, they ensure reliable, durable connections between battery packs while protecting against moisture, corrosion, and damage. Their flexibility also enables efficient space use in compact EV designs, enhancing system performance, safety, and longevity.