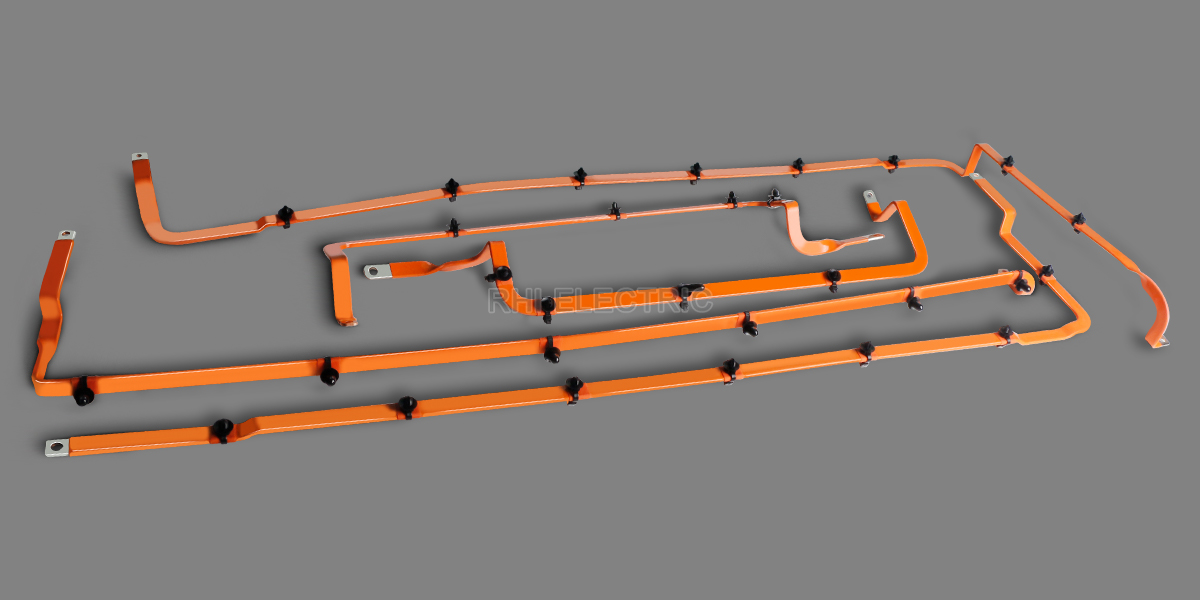

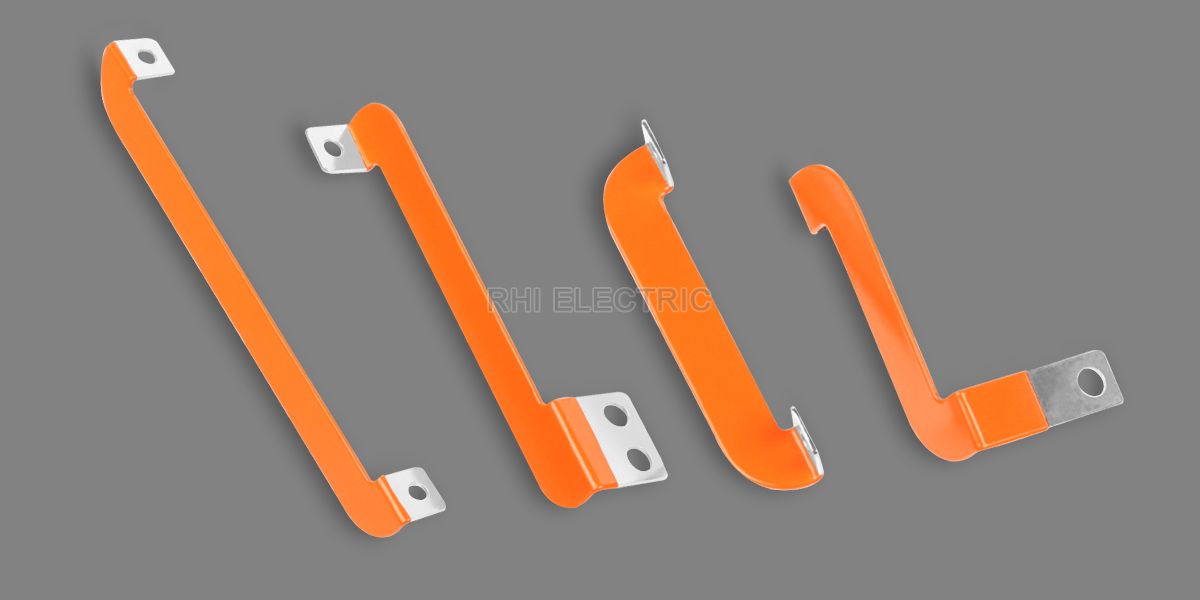

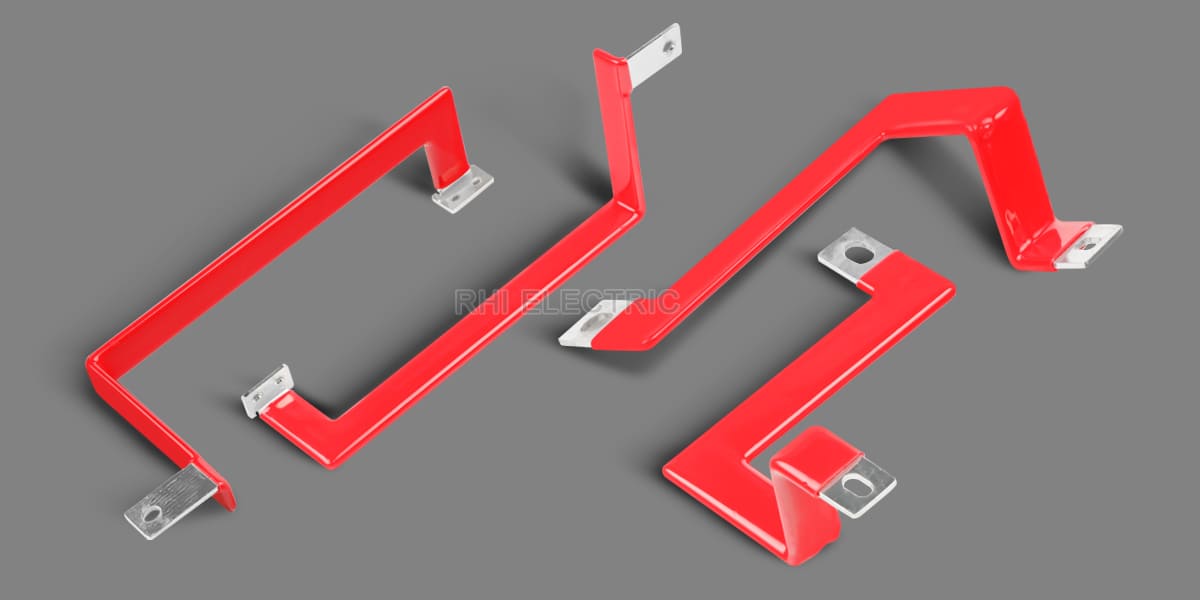

Extruded Rigid Copper Busbar

Rigid busbar is produced through an extrusion process, featuring high strength & excellent conductivity. Made of premium copper, power busbar with PA12 or PVC insulation, provides excellent vibration & wear resistance, multi-dimensional forming, saving installation space & time.

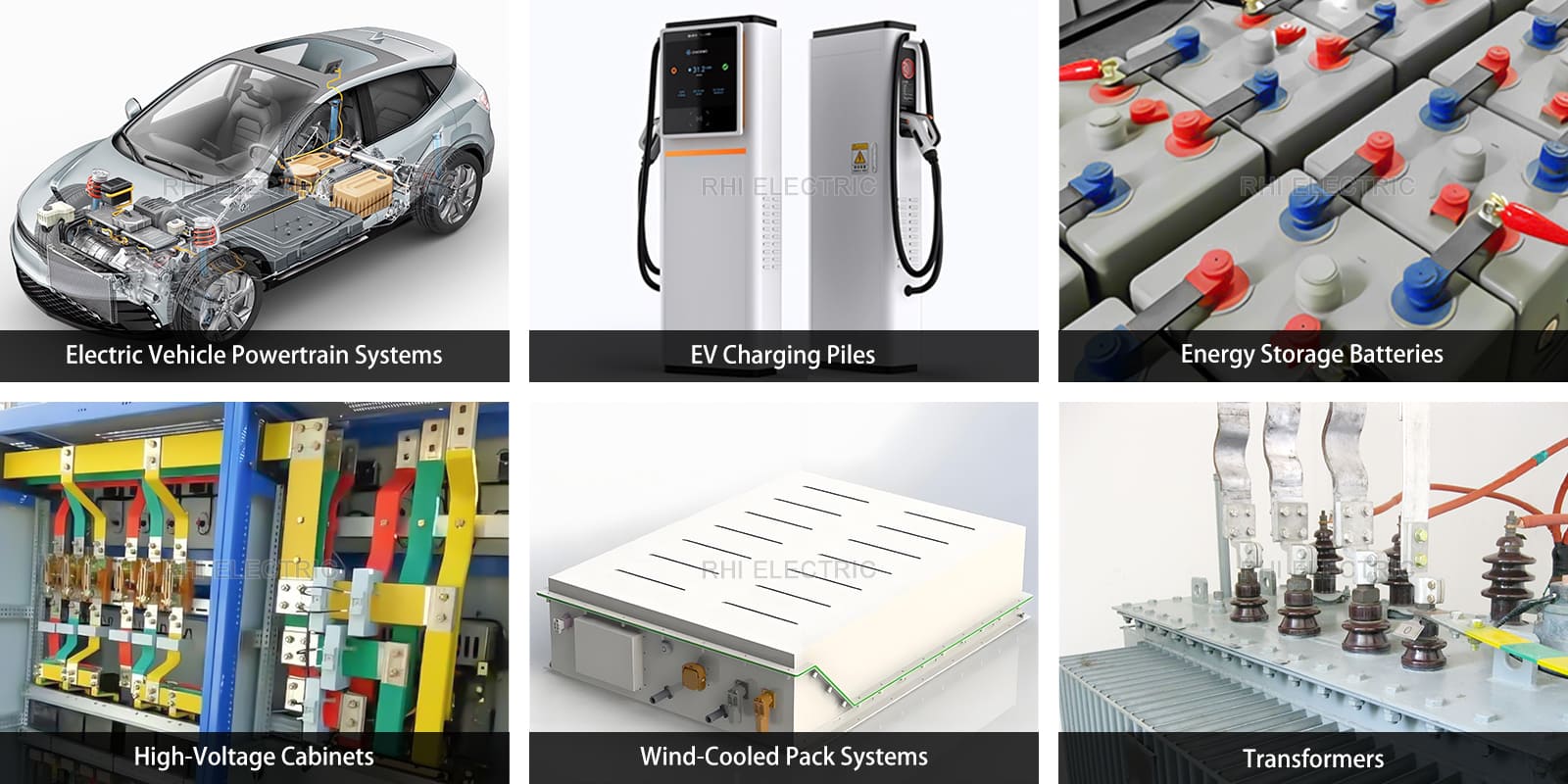

Application

Extruded copper busbars are widely used in various electrical systems due to their excellent conductivity and durability, significantly improving system efficiency and reliability.

-

Electric Vehicle Batteries: Extruded copper busbars provide stable current conduction and excellent insulation in electric vehicle batteries, ensuring the safety and reliability of the battery system.

-

EV Charging Piles: In charging stations, copper busbars enable efficient power transmission with corrosion resistance and oxidation protection, enhancing the efficiency and safety of the charging process.

-

Energy Storage Batteries: Insulated busbars play a critical role in current connections within energy storage systems, maintaining superior electrical performance under high temperatures and large currents, ensuring stable energy storage and release.

-

High-Voltage Cabinets: Extruded copper busbars are used in high-voltage cabinets, offering excellent insulation and heat dissipation, supporting the safe operation of high-current loads.

-

Air-Cooled Pack Systems: In air-cooled Pack systems, copper busbars enhance heat dissipation, effectively preventing thermal runaway and ensuring stable system operation.

-

Transformer: Electrical bus bars are used for internal and external connections in transformers, ensuring stable current transmission and reliable component connections, preventing electrical faults, and adapting to high-temperature, high-load conditions.

Spec Sheet

|

Thickness |

Insulating Material |

Withstand Voltage |

Temperature Resistant |

|

0.4-0.8mm |

PA12 |

2700V |

150°C |

|

0.5-2mm |

PVC |

35OOV |

-40-125°C |

Product Details

|

Customization: |

Customized packaging: Min. order: 100 Customized logo: Min. order: 100 |

|

Material Standard: |

T2 Copper ( E-CU58, CU-ETP, C11000, C1100 ) TU2 ( OF-CU, CU-OFE, CU-OF, C10100, C1011 ) Aluminium (1060 ) Other materials customizable. |

|

Surface Treatment: |

Bare, Tin Plating |

|

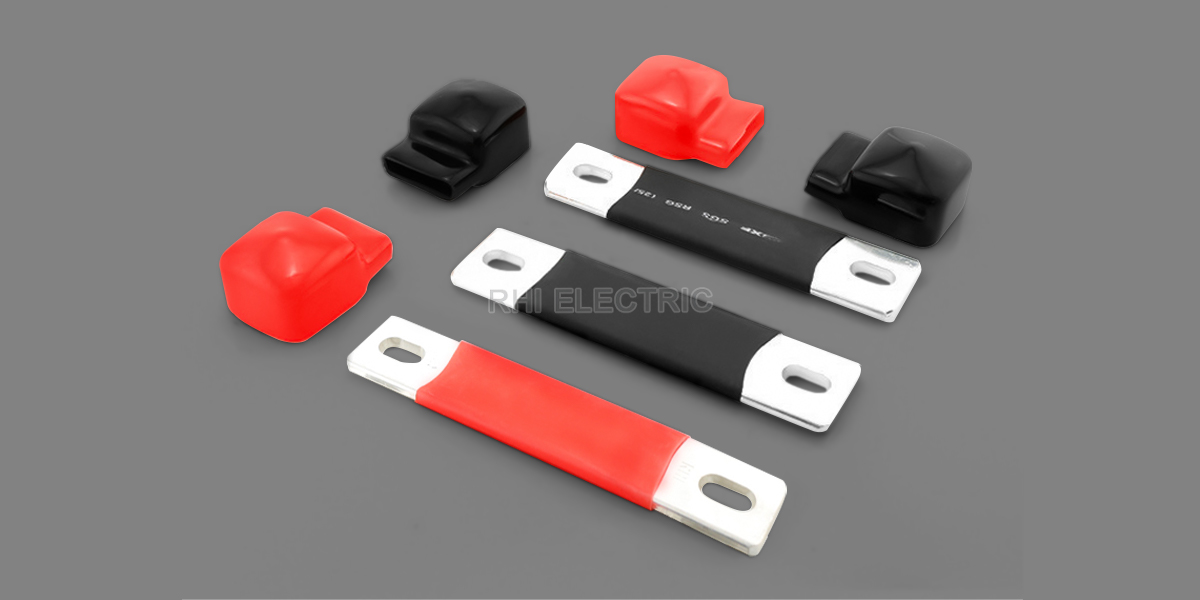

Insulation: |

PVC, PA12, PA11 |

|

Operating Temperature: |

-40℃-125℃ |

|

Available Components: |

Cable Ties, Labels, Laser Marking, Anti-collision Foam, etc. |

|

Quote Response Time: |

After receiving the drawings and verifying their feasibility, it will take 5-7 days to make a quotation. |

|

Quality Management Standard: |

Meet Auto Industry IATF16949 |

|

Eco-friendly Certificate: |

RoHS, REACH |

|

Delivery Time: |

The delivery time will take about 15-20 days after payment. |