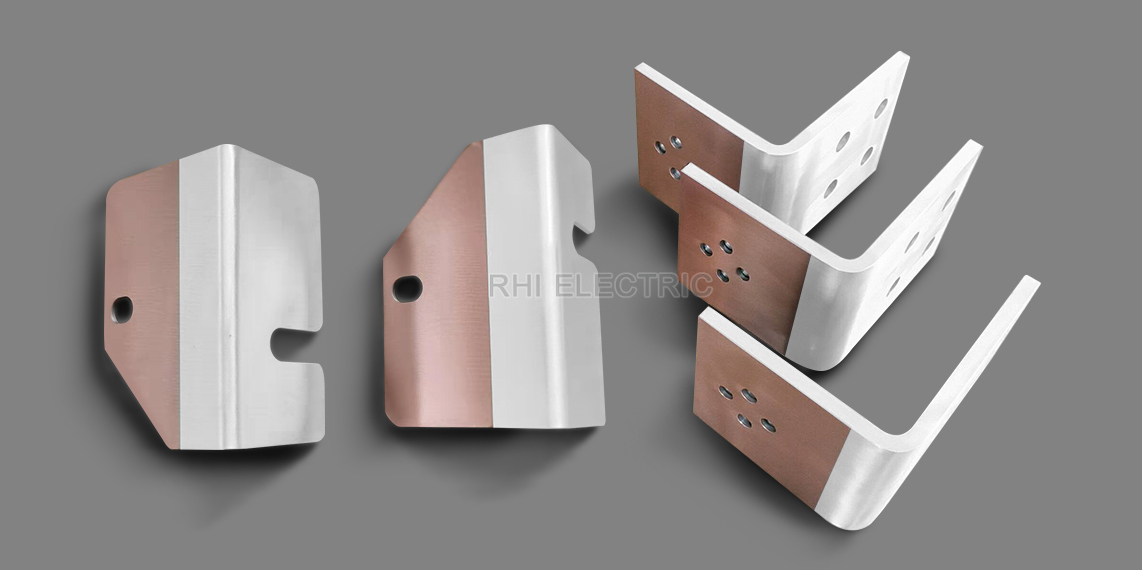

Copper-to-Aluminium Composite Busbars for Power Applications

RHI uses advanced diffusion welding to produce copper-aluminium busbars, with aluminium as the primary conductor and rigid copper welded at the ends. This lightweight and cost-effective composite busbar is ideal for cost-sensitive power connections, combining copper's conductivity with aluminium's low weight, ensuring excellent performance while reducing equipment weight.

Cu-Al bimetallic material is an advanced solution used across industries. Through diffusion brazing, T2 copper is securely bonded to 6-series aluminium, forming a permanent joint. This process preserves the properties of both materials and supports continuous automated production.

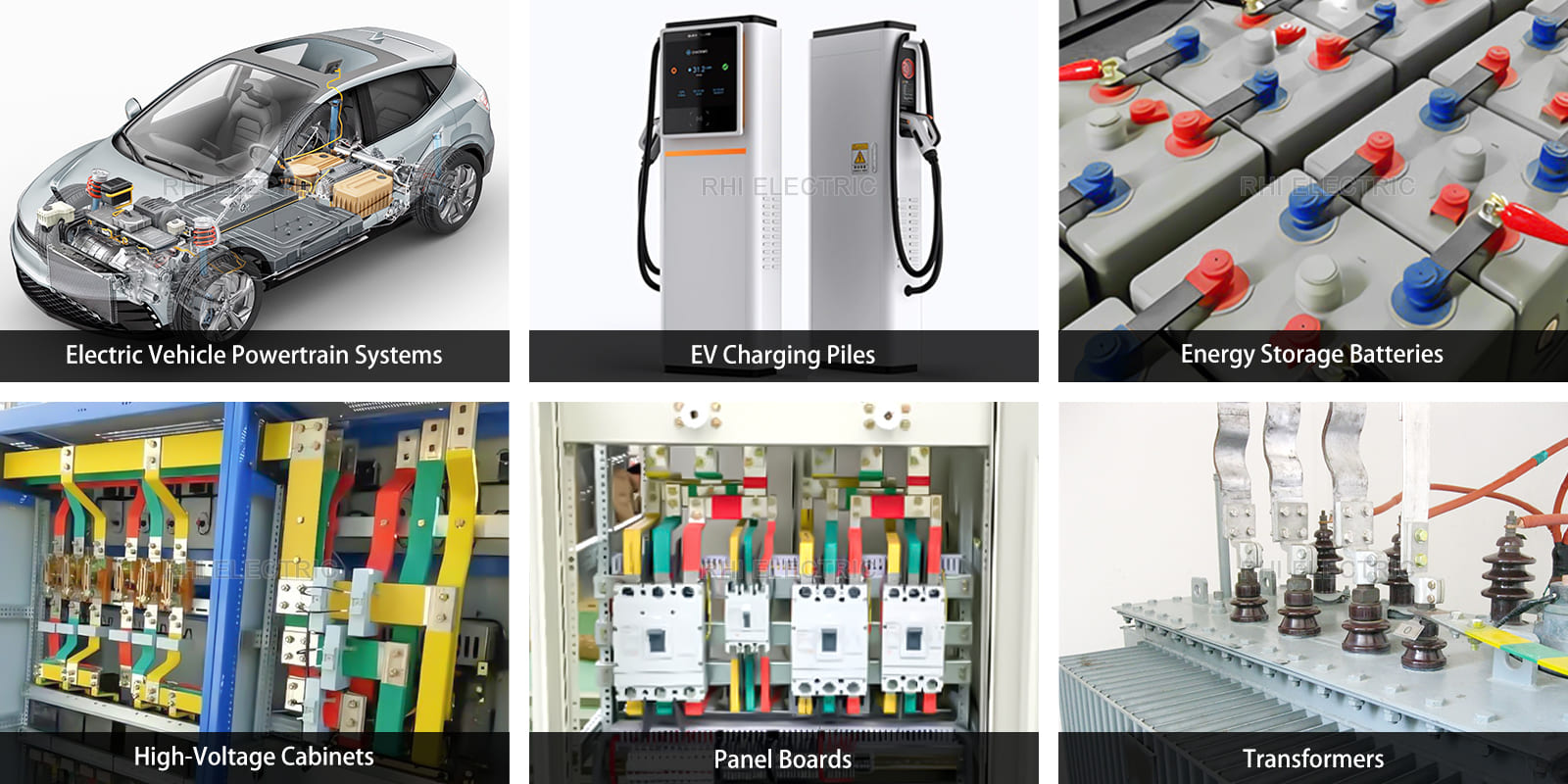

These composite busbars are increasingly replacing copper busbars in EV battery packs, energy storage systems, high-voltage cabinets, panel board, and air-cooled Pack systems, etc. They effectively prevent issues like surface oxidation, arcing, and overheating, resulting in lower power consumption and providing substantial economic and practical advantages.

Features

- Low density and lightweight, reducing material and shipping costs.

- Excellent electrical performance, equivalent to 86% of pure copper's conductivity.

- Good tensile strength, flexibility, and elongation.

- Strong, with excellent resistance to oxidation and corrosion.

Product Details

|

Conductor Material: |

Copper material: T2 Y2 Aluminium material: 6101 T63 Or other materials upon request. |

|

Surface Treatment: |

Nickel Plating Tin Plating Silver Plating |

|

Edge: |

Full Round Edges Rounded Corners Square Corners |

|

Width & Length: |

As your request. |

|

Insulating Material: |

PVC (dipping), PA12, EVA, PE and Epoxy Powder Coating |

|

Quote Response Time: |

After receiving the drawings and verifying their feasibility, it will take 5-7 days to make a quotation. |

|

Delivery Time: |

The delivery time will take about 15-20 days after payment. |

|

Certificate: |

IATF16949/ ISO45001/ ISO14001 |

|

File Formats Accepted: |

JPG DWG DXF |