Copper Clad Aluminium Busbar for New Energy

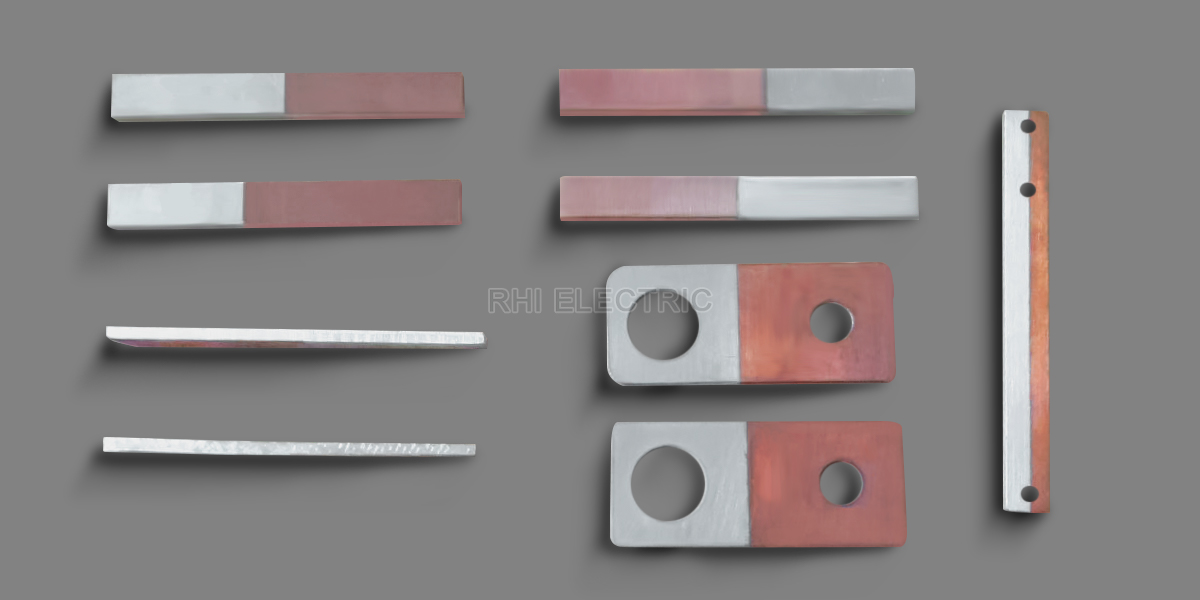

The copper-clad aluminium (CCA) busbar, also known as a bimetal conductive bar, represents the third generation of energy-saving conductor materials following copper and aluminium. Widely used in power transmission and distribution, it features an aluminium core encased in a copper layer. The CCA busbar offers the combined benefits of both metals, providing high electrical conductivity and reduced weight.

In the new energy industry, combining copper and aluminium is ideal due to copper's excellent thermal conductivity and aluminium's lightweight and cost-effectiveness. This blend enhances heat dissipation and offers design flexibility. Copper ensures efficient heat management, while aluminium reduces overall weight, ideal for weight-sensitive applications. Aluminium's affordability aids cost control, and both metals' good corrosion resistance ensures stability in diverse environments. This strategy balances performance, cost, and lightweight design.

Technical Parameters Reference

|

Current Capacity: |

86% pure copper (less 14% than copper busbar) |

|

DC Resistivity: |

≤0.02554Ω·mm2/m (soft) ≤0.02606Ω·mm/m (hard) |

|

Elongation: |

≥11% (soft) ≥1.5% (hard) |

|

Tensile Strength: |

≥90MPa (soft) ≥110MPa (hard) |

|

Shear Strength: |

≥35MPa |

Features

- Low density & lightweight: A copper-clad aluminium busbar weighs only 44% of a copper bus bar, reducing material and logistics costs.

- Good performance: Performance is good, but the current capacity is only 86% of the copper busbar.

- Energy-saving: Copper-aluminium composite busbar is a green product to save energy and environmental protection.

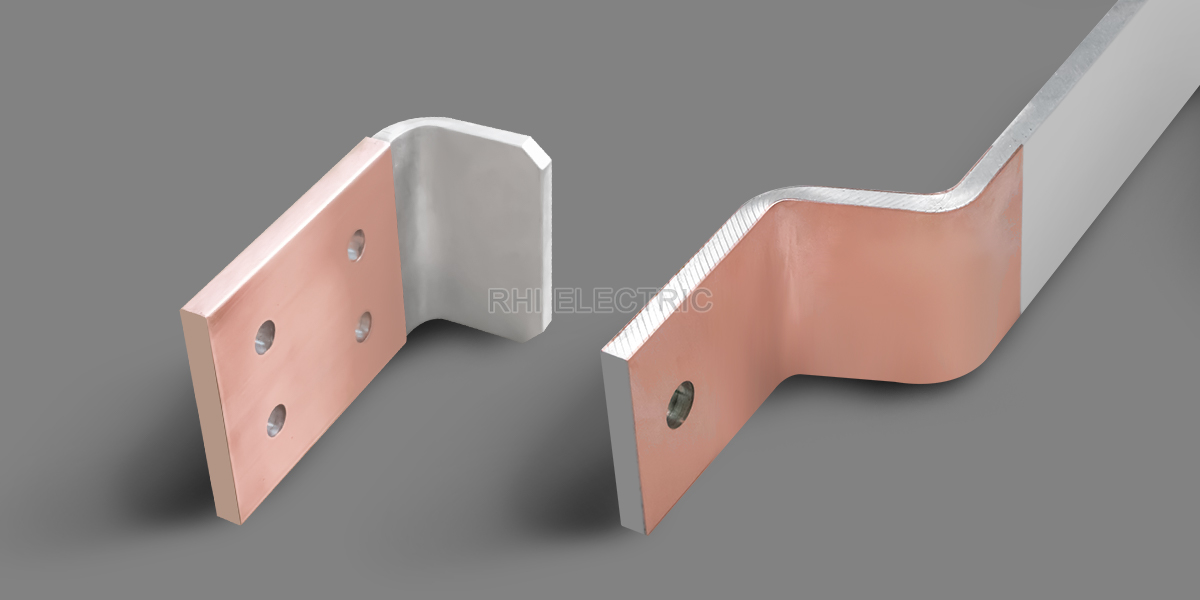

- Good mechanical properties: It has good tensile strength, bendability and elongation.

- Stable & durable: The surface is the same as copper bus bar, it has high strength, anti-oxidation and corrosion resistance.

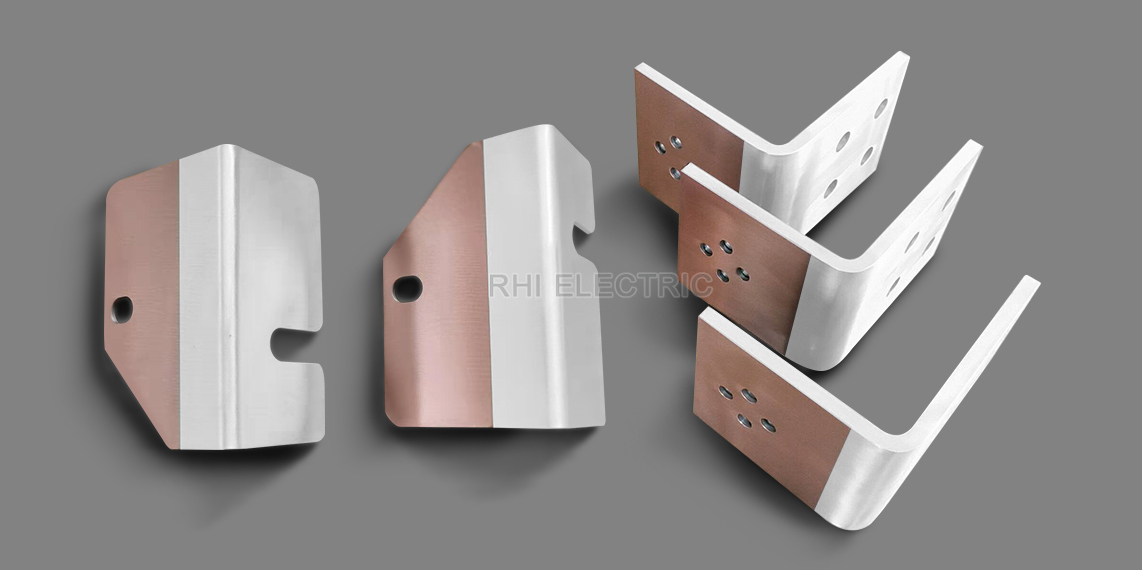

Product Details

|

Conductor Material: |

Copper material: T2 Aluminium material: 1060 Or other materials per your request. |

|

Surface Treatment: |

Nickel Plating Tin Plating Silver Plating |

|

Edge: |

Full Round Edges Rounded Corners Square Corners |

|

Width & Length: |

As your request. |

|

Insulating Material: |

PVC (dipping), PA12, EVA, PE and Epoxy Powder Coating |

|

Quote Response Time: |

After receiving the drawings and verifying their feasibility, it will take 5-7 days to make a quotation. |

|

Delivery Time: |

The delivery time will take about 15-20 days after payment. |

|

Certificate: |

IATF16949/ ISO45001/ ISO14001 |

|

File Formats Accepted: |

JPG DWG DXF |

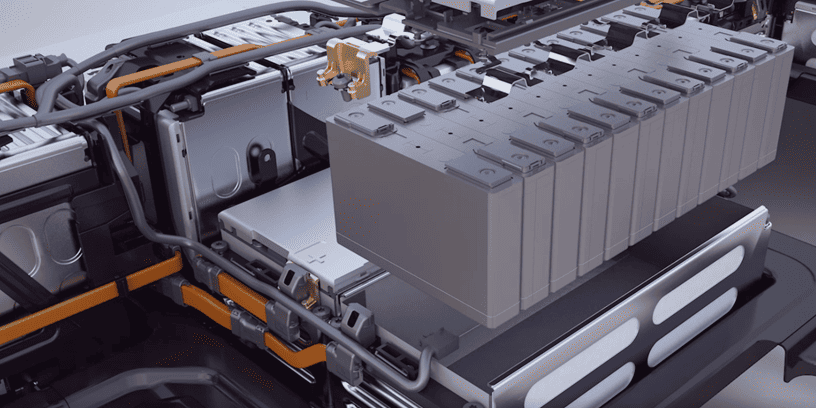

Applications

Using specific processes to leverage the properties of copper and aluminium, the interface between the two metals is fused or diffused to form a tight metallurgical bond, creating a bimetallic composite conductor. Copper-aluminium composite busbars are an excellent choice for power connections in electric vehicle battery packs, offering efficient current-carrying capabilities and enhanced performance in energy distribution.